Function of Safety Valve

The main function of a safety valve is to automatically relieve excess pressure from a system to prevent damage or failure. When the pressure in a steam system exceeds a pre-determined set point, the safety valve opens to discharge steam, thereby reducing the pressure back to a safe level.

In the context of a steam system, this function is particularly crucial. Steam boilers and other pressurized equipment operate under high temperatures and pressures. If the pressure becomes too high, there is a risk of explosion or rupture, which could cause significant damage, injury, or loss of life. A safety valve ensures that this risk is minimized.

Safety valves are typically spring-loaded devices that close tightly when the system pressure is within safe limits and automatically open when the pressure exceeds the set threshold. After the pressure returns to normal, the valve re-seals itself.

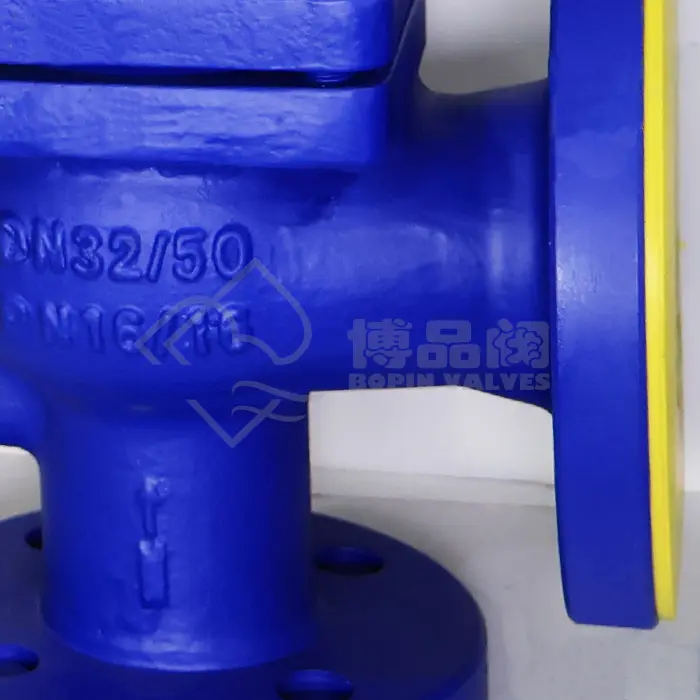

Design Principles of DIN Safety Valves

DIN standards for safety valves ensure a high level of performance, reliability, and safety in steam systems. The design of a DIN safety valve includes the following key features:

Set Pressure: The set pressure is the threshold at which the safety valve opens. This is usually determined by the design pressure of the steam system and should be calibrated precisely.

Blow-off Pressure: The valve should open fully at a pressure that is typically 10% to 15% higher than the set pressure. This ensures that excess steam is vented quickly to reduce the risk of over-pressurization.

Valve Body: The valve body must be made of high-strength materials to withstand the pressure and temperature conditions present in the steam system. Common materials include carbon steel, stainless steel, and bronze.

Seat and Disc: The seat and disc are the critical sealing components of the valve. The design of the seat ensures a tight seal when the valve is closed, while the disc allows for the quick opening and closing of the valve when the pressure fluctuates.

Spring Mechanism: A spring-loaded mechanism is used to control the opening and closing of the valve. The spring is calibrated to the desired pressure setting. If the system pressure exceeds this set point, the spring force is overcome, causing the valve to open.

Drainage: The safety valve design must include provisions for discharging steam and preventing any water accumulation, which could affect the performance of the valve.

Leakage Prevention: One of the critical factors for ensuring the safety of a steam system is preventing leakage. The DIN safety valve design must ensure that it does not leak when the system is under normal operating pressure.

Testing and Certification: DIN safety valves must be rigorously tested to meet specific performance criteria, including the set pressure, blow-off pressure, and leakage rates. These tests are performed in compliance with the relevant DIN standards to ensure the valve performs reliably under real-world conditions.

Key DIN Standards for Safety Valves

Several DIN standards are relevant for safety valves used in steam systems. These standards define various requirements, including material specifications, performance criteria, and testing procedures.

DIN EN 13709: This is the European standard that provides the general requirements for safety valves used in pressure systems, including steam boilers. It outlines criteria for design, materials, performance, and testing.

DIN EN 12266: This standard deals with the testing of safety valves and covers various types of tests to verify that the valve performs as expected, including the seat tightness test, functional testing, and overpressure tests.

DIN 3320: This standard addresses the dimensional requirements for safety valves and ensures that the valve sizes match the application’s requirements.

DIN 4812: This standard specifies the requirements for valves used in steam systems, including safety valves, ensuring compatibility with steam pressures and temperatures.

DIN 2533: This standard provides specifications for the design and installation of steam boiler safety valves, including guidelines for materials, calibration, and maximum pressure ratings.

Application of DIN Safety Valves in Steam Systems

Steam systems are used in various industries, from power plants to food processing and chemical manufacturing. In these systems, safety valves perform several key roles:

Boiler Protection: Steam boilers are one of the most common applications of safety valves. A boiler safety valve protects the system from over-pressurization, which can cause boiler explosions. The valve automatically releases excess pressure to prevent the boiler from reaching dangerous levels.

Pressure Relief in Piping Systems: Safety valves are also used in steam piping systems to maintain a safe operating pressure. If there is a sudden surge in pressure, the safety valve will relieve the pressure and ensure the integrity of the piping.

Protection of Pressure Vessels: Steam is often used in pressure vessels for processes like sterilization or distillation. A DIN safety valve is essential to ensure these vessels do not experience excessive internal pressure, preventing failure.

Superheated Steam Systems: In systems that use superheated steam, the safety valve must be capable of handling the higher pressures and temperatures involved. Specially designed DIN safety valves are used to ensure the safe operation of such systems.

Industrial Applications: Industries such as oil refineries, chemical plants, and power stations rely heavily on safety valves to protect both equipment and personnel from over-pressurization. In these industries, safety valves are essential for the safe operation of steam turbines, condensate recovery systems, and various other pressurized equipment.

Energy Generation: Steam turbines used in electricity generation often incorporate DIN safety valves to protect against over-pressurization, ensuring that the turbine and its associated components are not damaged.

Benefits of DIN Safety Valves

Reliability: DIN safety valves are designed to be highly reliable and durable, providing protection over long periods without frequent maintenance or failure.

Compliance with International Standards: As DIN is a widely recognized and respected standard, using DIN-certified safety valves ensures that the system complies with global safety standards.

Cost-Effectiveness: Properly functioning safety valves prevent costly equipment damage and potential downtime due to pressure-related issues.

Safety: The primary benefit of a safety valve is the enhanced safety it provides. By preventing dangerous over-pressurization, safety valves protect both personnel and equipment, reducing the risk of accidents and fatalities.

Performance Assurance: The rigorous testing and certification process ensures that DIN safety valves operate effectively, maintaining a safe working pressure under varying operating conditions.

Conclusion

The DIN safety valve is an essential device in any steam system, offering a critical layer of protection against excessive pressure, which can lead to catastrophic failure. Its design is carefully calibrated to open and close at specific pressures, ensuring optimal protection. By adhering to stringent DIN standards, these valves provide reliable, safe, and efficient operation across various industrial sectors, from power generation to manufacturing and processing industries.

Incorporating a DIN safety valve into a steam system is a prudent decision for maintaining system integrity and safeguarding against the risks associated with over-pressurization. Proper selection, installation, and maintenance of these valves are crucial in ensuring long-term system reliability and operational safety.