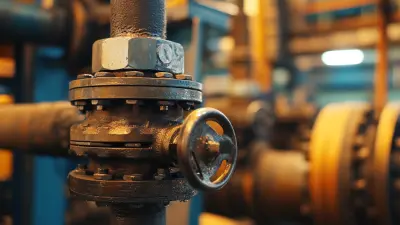

Welded Bonnet But-Welded End Forged Steel Gate Valves - Top OEM Suppliers & Exporters

When sourcing top-quality **Welded Bonnet But-Welded End Forged Steel Gate Valves**, choosing reputable **manufacturers** ensures superior performance and durability. Our valves are engineered for exceptional reliability across various industrial applications. At YONGJIA BOPIN VALVE FACTORY, we take pride in crafting high-performance valves that meet rigorous quality standards. Through collaboration with trusted **factories**, we guarantee that each valve is made with premium materials and cutting-edge technology. These valves are built to withstand demanding conditions, offering seamless operation. Experience the difference in quality and performance with our welded bonnet but-welded end forged steel gate valves. Your satisfaction remains our top priority.10 Essential Tips For Welded Bonnet But-Welded End Forged Steel Gate Valves Custom Solutions, Leads the Global Market

When it comes to industrial applications, the choice of valves can significantly impact operational efficiency and reliability. At BOPIN VALVE, we understand the importance of custom solutions, especially for welded bonnet but-welded end forged steel gate valves, which are essential in demanding environments. Here are 10 essential tips for choosing the right valve that can help you optimize your operations while remaining competitive in the global market. Firstly, consider your specific requirements in terms of materials and sizes. Customized valves from BOPIN VALVE ensure that your operations run smoothly and are adept at handling various pressure ratings and specialized applications, which is critical for maintaining system integrity. Our expertise allows us to tailor designs that meet both standard and unique operational demands, enhancing performance and reliability. Secondly, working with a reliable supplier that offers expert design capabilities like BOPIN VALVE can streamline your procurement process. By leveraging our ability to create customized solutions, you not only ensure that the valves are perfectly suited for their intended use but also gain a partner that is committed to efficiency and quality. In an ever-competitive global market, investing in bespoke valve solutions can lead to significant long-term savings and operational advantages. Choose BOPIN VALVE for your valve requirements and experience the difference in quality and performance.

10 Essential Tips For Welded Bonnet But-Welded End Forged Steel Gate Valves Custom Solutions, Leads the Global Market

| Tip No. | Tip Description | Key Benefits | Industry Application |

|---|---|---|---|

| 1 | Choose the Right Material | Enhanced durability and corrosion resistance | Oil & Gas |

| 2 | Optimize Valve Size | Improved flow rates and pressure drop | Water Treatment |

| 3 | Inspect Regularly | Prevention of leaks and failures | Power Generation |

| 4 | Use High-Quality Seals | Longer service life and leak prevention | Pulp & Paper |

| 5 | Ensure Proper Installation | Reduces the risk of operational issues | Chemical Processing |

| 6 | Implement Automation | Increased efficiency and precision | Manufacturing |

| 7 | Use Pressure Testing | Ensures integrity and reliability | HVAC Systems |

| 8 | Keep Up with Standards | Compliance with regulations | Construction |

| 9 | Educate Staff | Improved overall safety and performance | Water Supply |

| 10 | Plan for Maintenance | Minimizes downtime and costs | Mining |

Insider Tips For Welded Bonnet But-Welded End Forged Steel Gate Valves Sets the Industry Standard Ahead of the Curve

E

Emily Rivera

Very pleased with my order! The customer service was knowledgeable and very helpful.

21 June 2025

J

Jack Clark

The quality is hard to beat! Outstanding after-sales service and very professional representatives.

03 June 2025

D

David Martinez

Impressive quality! The team was quick to assist with all my questions.

10 June 2025

M

Mila Wilson

Stellar quality! The after-sales personnel are incredibly dedicated and professional.

14 June 2025

Z

Zachary Young

The quality really impressed me! The after-sales support was professional and thorough.

14 May 2025

M

Maya Taylor

I couldn’t be happier! The quality is superb, and the support is unrivaled.

30 June 2025