TRIPLE OFFSET BUTTERFLY VALVE MANUFACTURER

Overview of API 609 Standard

API 609 is the American Petroleum Institute standard that covers butterfly valves with flanged, lugged, and wafer ends. It specifies requirements for design, materials, pressure–temperature ratings, dimensions, testing, and inspection. Valves manufactured to API 609 are typically classified as either resilient-seated or high-performance metal-seated butterfly valves. Triple offset butterfly valves fall under the high-performance category and are intended for applications where zero leakage and fire-safe performance are essential.

Triple Offset Design Concept

The defining feature of this valve is its triple offset geometry, which eliminates the rubbing action between the disc and seat during operation. The three offsets are:

First Offset (Shaft Offset): The shaft is positioned behind the plane of the sealing surface, reducing interference between the disc and seat during opening and closing.

Second Offset (Radial Offset): The shaft is offset from the centerline of the valve bore, allowing the disc to move away from the seat early in the opening stroke.

Third Offset (Cone Angle Offset): The sealing surfaces are machined at an inclined cone angle rather than being concentric. This creates a cam-like action that ensures contact between disc and seat only at the final closing position.

This triple offset configuration results in a true torque-seated, metal-to-metal seal, minimizing wear and enabling excellent sealing performance even after many cycles.

First Offset (Shaft Offset): The shaft is positioned behind the plane of the sealing surface, reducing interference between the disc and seat during opening and closing.

Second Offset (Radial Offset): The shaft is offset from the centerline of the valve bore, allowing the disc to move away from the seat early in the opening stroke.

Third Offset (Cone Angle Offset): The sealing surfaces are machined at an inclined cone angle rather than being concentric. This creates a cam-like action that ensures contact between disc and seat only at the final closing position.

This triple offset configuration results in a true torque-seated, metal-to-metal seal, minimizing wear and enabling excellent sealing performance even after many cycles.

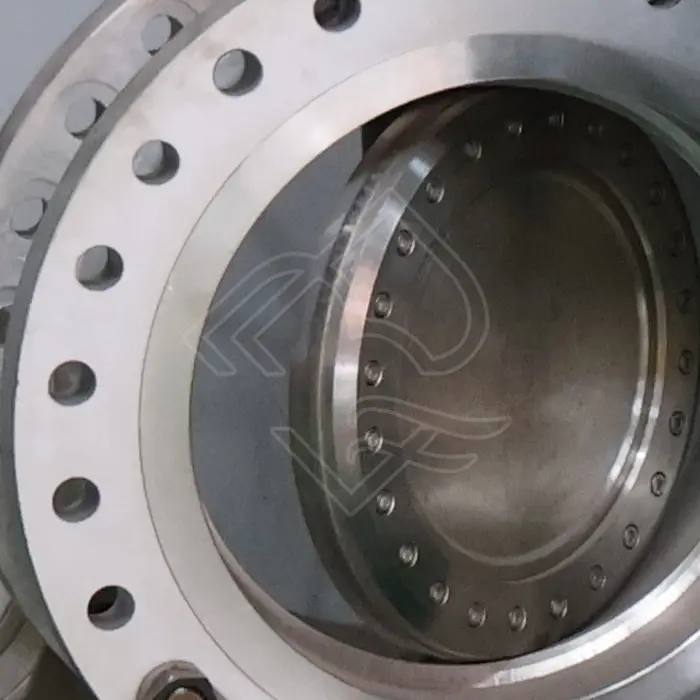

Flange End Construction

Flange end triple offset butterfly valves are supplied with integral flanges drilled in accordance with international standards such as ASME B16.5, ASME B16.47, or EN 1092. Flanged ends provide robust and secure bolted connections to the pipeline, making them suitable for high-pressure and large-diameter applications. Compared with wafer or lug types, flanged end valves offer improved alignment, rigidity, and ease of installation in critical services.

The flange end design also simplifies maintenance, as the valve can be removed without disturbing adjacent piping when proper isolation is in place.

The flange end design also simplifies maintenance, as the valve can be removed without disturbing adjacent piping when proper isolation is in place.

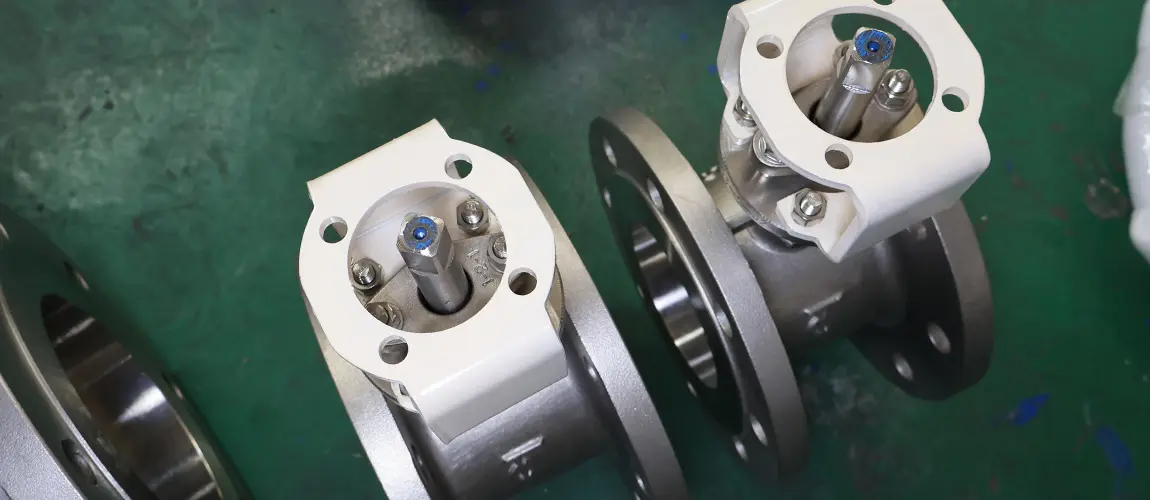

Worm Gear Operation

Worm gear operation is commonly used for medium to large size triple offset butterfly valves or where higher operating torque is required. The worm gear assembly consists of a handwheel connected to a worm and gear mechanism that multiplies torque and allows smooth, controlled operation.

Key advantages of worm gear operation include:

- Reduced operating effort, making it easier to operate large valves manually

- Self-locking mechanism, preventing accidental movement due to line pressure or vibration

- Precise control, especially important for valves used in throttling or modulating service (where permitted)

- Compatibility with actuators, as worm gear units can be easily adapted for electric or pneumatic actuation

Key advantages of worm gear operation include:

- Reduced operating effort, making it easier to operate large valves manually

- Self-locking mechanism, preventing accidental movement due to line pressure or vibration

- Precise control, especially important for valves used in throttling or modulating service (where permitted)

- Compatibility with actuators, as worm gear units can be easily adapted for electric or pneumatic actuation

Materials of Construction

API 609 triple offset butterfly valves are available in a wide range of materials to suit different service conditions. Typical materials include:

Body: Carbon steel (A216 WCB), low-temperature carbon steel (LCB/LCC), alloy steel, stainless steel (CF8, CF8M), duplex and super duplex stainless steels

Disc: Stainless steel, duplex stainless steel, alloy steel with hardfacing

Seat: Laminated metal seal, often consisting of stainless steel with graphite or other high-temperature sealing layers

Stem: Stainless steel or high-strength alloy steel

Material selection is based on pressure, temperature, corrosion resistance, and process fluid characteristics.

Body: Carbon steel (A216 WCB), low-temperature carbon steel (LCB/LCC), alloy steel, stainless steel (CF8, CF8M), duplex and super duplex stainless steels

Disc: Stainless steel, duplex stainless steel, alloy steel with hardfacing

Seat: Laminated metal seal, often consisting of stainless steel with graphite or other high-temperature sealing layers

Stem: Stainless steel or high-strength alloy steel

Material selection is based on pressure, temperature, corrosion resistance, and process fluid characteristics.

Sealing & Performance

The metal-seated triple offset design provides bidirectional, bubble-tight shut-off, typically meeting leakage Class A or zero leakage requirements as defined by API 609. The torque-seated seal ensures that sealing force increases with closing torque, making the valve suitable for high-pressure applications.

These valves are also inherently fire-safe due to their metal-to-metal sealing design, making them compliant with fire-safe standards such as API 607 when tested accordingly.

Pressure and Temperature Range

API 609 flange end triple offset butterfly valves are designed to operate over a wide pressure and temperature range. Depending on material selection and pressure class, they can handle pressures up to ASME Class 600 or higher and temperatures ranging from cryogenic levels to above 600°C. This versatility makes them suitable for steam, hydrocarbons, hot oil, and other severe services.

These valves are also inherently fire-safe due to their metal-to-metal sealing design, making them compliant with fire-safe standards such as API 607 when tested accordingly.

Pressure and Temperature Range

API 609 flange end triple offset butterfly valves are designed to operate over a wide pressure and temperature range. Depending on material selection and pressure class, they can handle pressures up to ASME Class 600 or higher and temperatures ranging from cryogenic levels to above 600°C. This versatility makes them suitable for steam, hydrocarbons, hot oil, and other severe services.

Applications

- Common applications include:

- Oil and gas transmission and processing

- Refining and petrochemical plants

- Power generation and steam systems

- LNG and cryogenic services (with appropriate design)

- High-temperature and high-pressure isolation duties

- They are primarily used as on/off isolation valves but can also be applied in limited control services where specified.

- Oil and gas transmission and processing

- Refining and petrochemical plants

- Power generation and steam systems

- LNG and cryogenic services (with appropriate design)

- High-temperature and high-pressure isolation duties

- They are primarily used as on/off isolation valves but can also be applied in limited control services where specified.

Advantages of API 609 Flange End Triple Offset Butterfly Valves

- Zero leakage, metal-to-metal sealing

- Long service life with minimal wear

- Compact and lightweight compared to gate or globe valves

- Fire-safe and suitable for severe service

- Reliable operation with worm gear for large sizes

- Long service life with minimal wear

- Compact and lightweight compared to gate or globe valves

- Fire-safe and suitable for severe service

- Reliable operation with worm gear for large sizes