0102030405

API 594 Stainless Steel Lug Type Dual Plate Check Valve

1. Overview of API 594 Stainless Steel Lug Type Dual Plate Check Valve

The API 594 Stainless Steel Lug Type Dual Plate Check Valve is a compact, high‑performance non‑return valve designed to prevent reverse flow in piping systems while maintaining minimal pressure loss. Manufactured in accordance with API 594, this valve is widely used in oil and gas, petrochemical, chemical processing, power generation, water treatment, marine, and general industrial services. The dual plate (also known as double door or split disc) design combines fast response, low cracking pressure, and short face‑to‑face dimensions, making it an ideal solution for space‑constrained installations and high‑cycle applications.

2. Applicable Standards and Design Codes

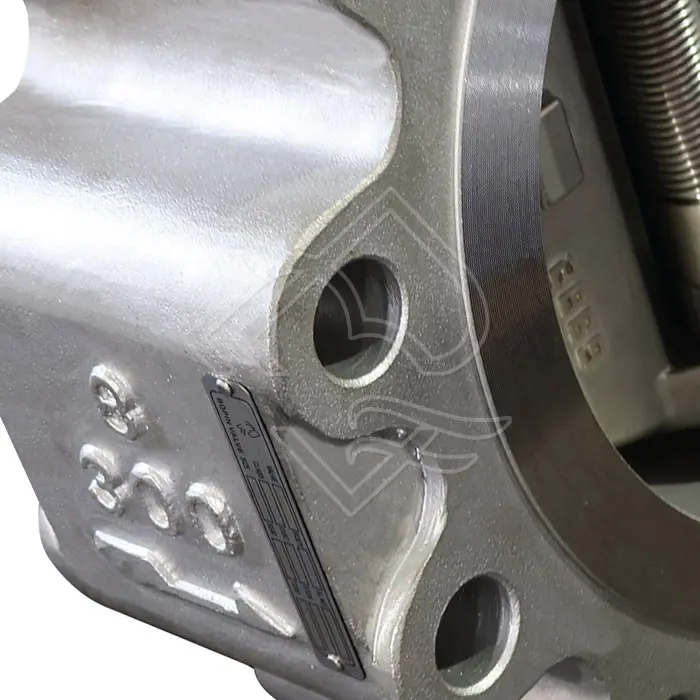

The valve is designed and manufactured to comply with API 594, which governs wafer and lug type check valves, including dual plate configurations. Face‑to‑face dimensions typically follow API 594 or ASME B16.10, ensuring interchangeability with other standard check valves. Flanged connections and drilling are compatible with ASME B16.5 or EN 1092‑1, depending on project requirements. Pressure‑temperature ratings are generally in accordance with ASME B16.34, while materials comply with ASTM standards such as ASTM A351 CF8, CF8M, or CF3M for stainless steel castings.

3. Construction and Design Features

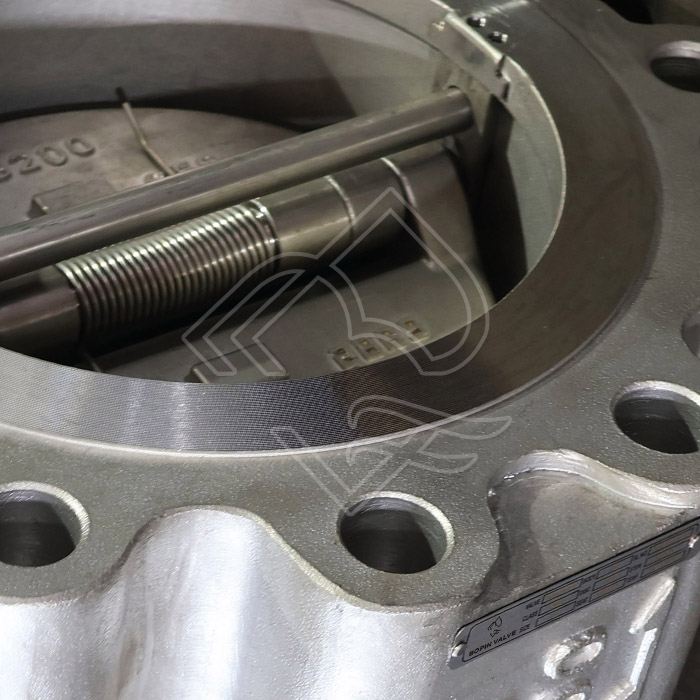

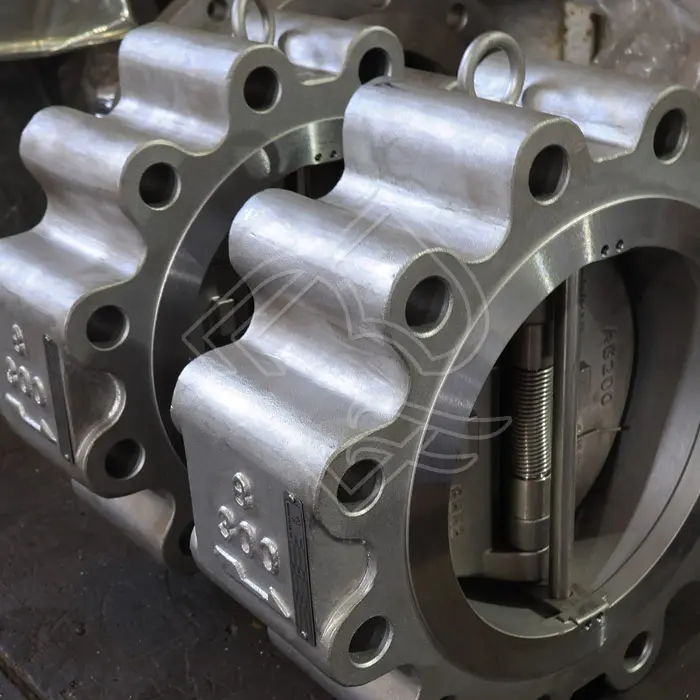

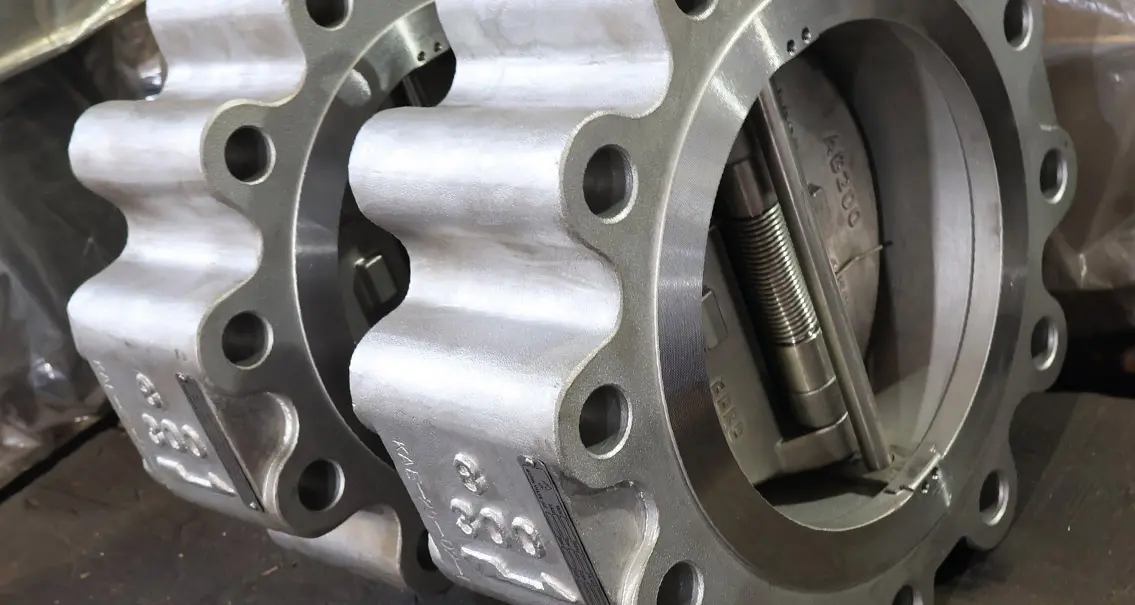

The lug type body incorporates threaded lugs around the periphery of the valve, allowing it to be bolted directly between two flanges. This configuration enables dead‑end service and facilitates easy removal of downstream piping without disturbing the upstream side. The dual plate assembly consists of two semicircular discs mounted on a central hinge pin. Each plate is spring‑loaded, ensuring rapid closing action as soon as forward flow decreases.

The compact body profile significantly reduces weight compared with conventional swing check valves. The short face‑to‑face dimension minimizes installation space and lowers material costs for piping supports and structural steel. Internal components are carefully engineered to provide smooth flow paths, reducing turbulence and pressure drop.

4. Materials of Construction

Stainless steel construction provides excellent corrosion resistance, strength, and durability. Common body materials include ASTM A351 CF8 (304 stainless steel) and CF8M (316 stainless steel), offering good resistance to a wide range of corrosive fluids. For more demanding environments, low‑carbon or molybdenum‑enhanced grades such as CF3 or CF3M are available to improve weldability and resistance to pitting and crevice corrosion.

Internal components such as discs, hinge pins, and springs are typically manufactured from stainless steel grades like AISI 304, 316, or precipitation‑hardened alloys, depending on service conditions. Soft or metal seats may be selected based on pressure, temperature, and shutoff requirements. Elastomeric seats provide bubble‑tight sealing at lower temperatures, while metal‑to‑metal seating is preferred for high‑temperature or abrasive services.

5. Operating Principle

During normal operation, forward flow pressure overcomes the spring force, causing the dual plates to open symmetrically. The split disc design reduces the moment of inertia, allowing the plates to respond quickly to changes in flow velocity. When flow decreases or reverses, the springs assist in rapidly closing the plates before reverse flow can fully develop. This fast closing action minimizes water hammer and protects pumps, compressors, and other critical equipment.

The central hinge pin and spring arrangement ensures balanced movement of the plates, reducing wear and extending service life. Because the plates open only partially compared with swing check valves, the risk of slamming is significantly reduced.

6. Performance Characteristics

One of the key advantages of the dual plate check valve is its low pressure drop. The streamlined internal geometry and short flow path reduce energy losses, contributing to improved system efficiency. The low cracking pressure allows the valve to open at minimal differential pressure, making it suitable for low‑pressure and low‑flow applications.

The lug type configuration provides excellent structural integrity and alignment between flanges. It also allows the valve to function as an isolation point when one side of the pipeline is removed, which is particularly beneficial in maintenance operations.

7. Installation and Maintenance

Installation of the API 594 stainless steel lug type dual plate check valve is straightforward. The valve can be installed in horizontal or vertical pipelines, provided the flow direction arrow on the body is correctly aligned with system flow. Proper flange alignment and uniform bolt tightening are essential to ensure leak‑free operation and prevent distortion of the valve body.

Maintenance requirements are minimal due to the simple internal design and reduced number of moving parts. Periodic inspection of springs, hinge pins, and seating surfaces is recommended, especially in high‑cycle or abrasive services. Stainless steel construction enhances longevity and reduces the frequency of replacement compared with carbon steel alternatives.

8. Applications

This valve type is suitable for a wide range of applications, including crude oil and refined petroleum pipelines, chemical processing units, offshore platforms, power plant auxiliary systems, cooling water circuits, and HVAC systems. Its corrosion resistance makes it particularly well suited for seawater, chemicals, and mildly acidic or alkaline media.

In pumping systems, the fast‑closing dual plate mechanism protects pumps from reverse rotation and pressure surges. In gas and vapor services, the lightweight plates and springs provide reliable non‑return performance even at high flow velocities.

9. Advantages

Key advantages of the API 594 stainless steel lug type dual plate check valve include compact size, lightweight construction, low pressure drop, quick response, and reduced water hammer. The lug type body allows for easy installation and maintenance, while stainless steel materials ensure excellent corrosion resistance and long service life. Compliance with international standards guarantees compatibility with global piping systems and project specifications.