SINGLE DISC WAFER TYPE CHECK VALVE MANUFACTURER

1.About API 594 Swing Check Valve

2. Key Characteristics of API 594 Swing Check Valve

3. Working Principle of a Swing Check Valve

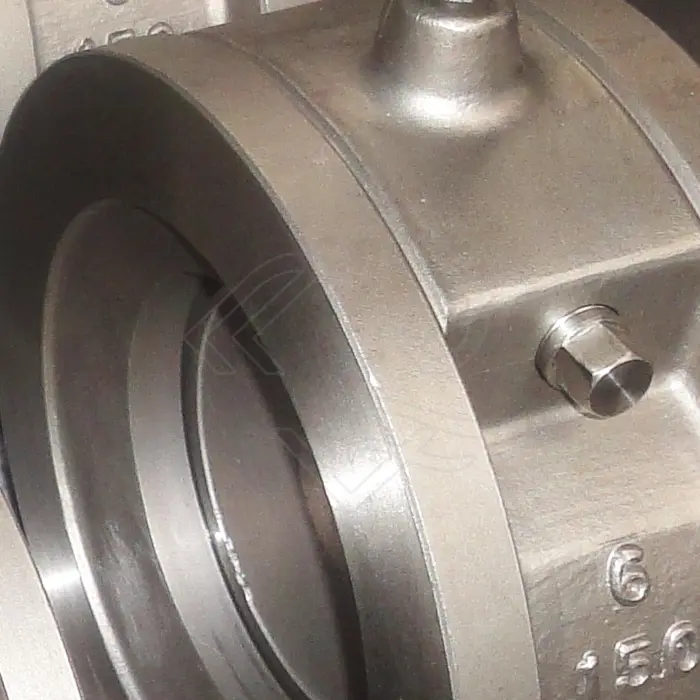

A swing check valve operates based on the principle of fluid pressure. When the fluid flows in the direction that the valve is designed to allow, the pressure forces the valve disc to swing open. This allows fluid to pass through the valve unobstructed. When the fluid flow stops or reverses direction, the valve disc swings shut due to the back pressure from the reverse flow or the weight of the disc itself, ensuring that no fluid flows back into the system.

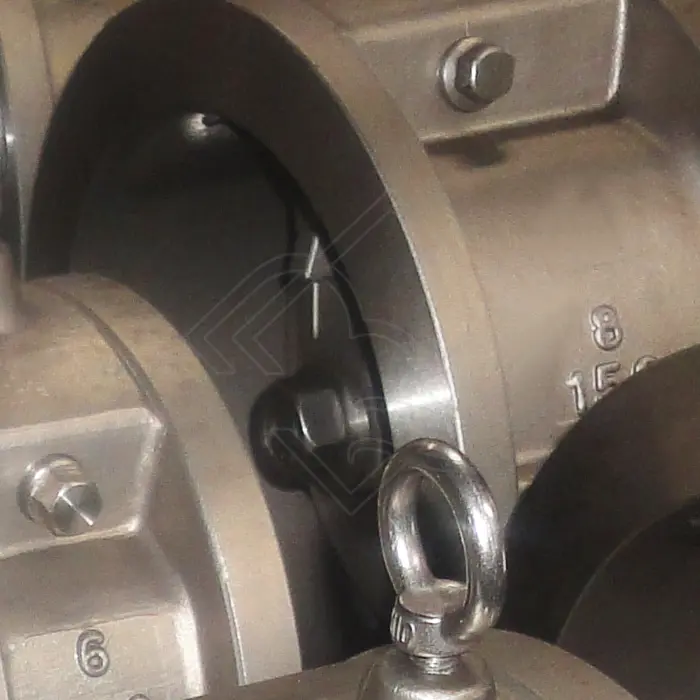

The swing mechanism is typically aided by a hinge pin or hinge pin assembly that allows the plate to move freely. The motion of the valve plate ensures that there is a tight seal when the valve is closed, preventing backflow and thus protecting downstream equipment from damage or contamination.