High-Quality Resilient Seated Butterfly Valve | Top Exporters & Suppliers

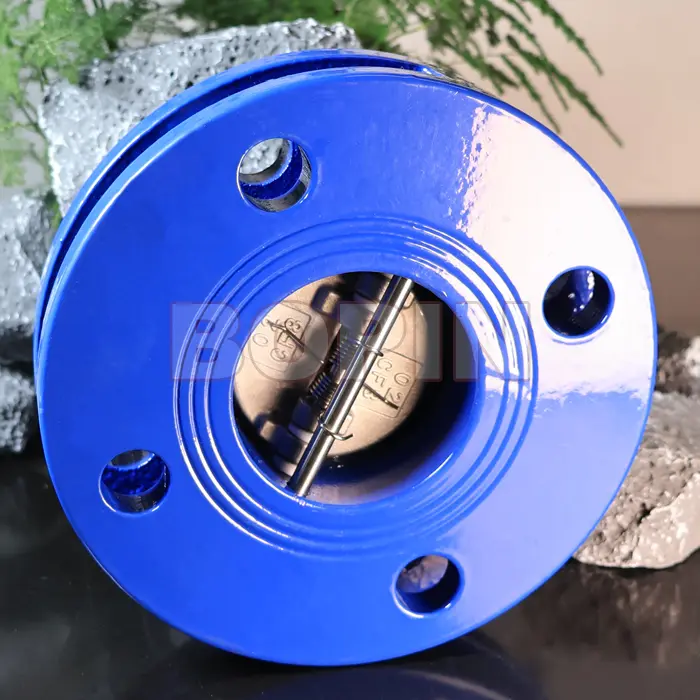

Introducing our Resilient Seated Butterfly Valve, designed for those who prioritize durability and efficiency in their operations. As a wholesale provider and exporter, I understand the needs of B2B purchasers looking for high-quality solutions that perform reliably under pressure. Our Butterfly Valves feature a resilient seating design that ensures a tight seal and exceptional flow control, making them perfect for various applications, Whether you're an exporter seeking to elevate your product offerings or a manufacturer in need of dependable components, our valves stand out for their robust construction and long-lasting performance. Manufactured at YONGJIA BOPIN VALVE FACTORY, we prioritize quality to meet international standards. Partner with us for competitive prices and unmatched service as you fulfill your business needs with our top-notch valve solutions. Let’s work together to enhance your operations!

Quick Tips To Resilient Seated Buttfly Valve Application Supplier

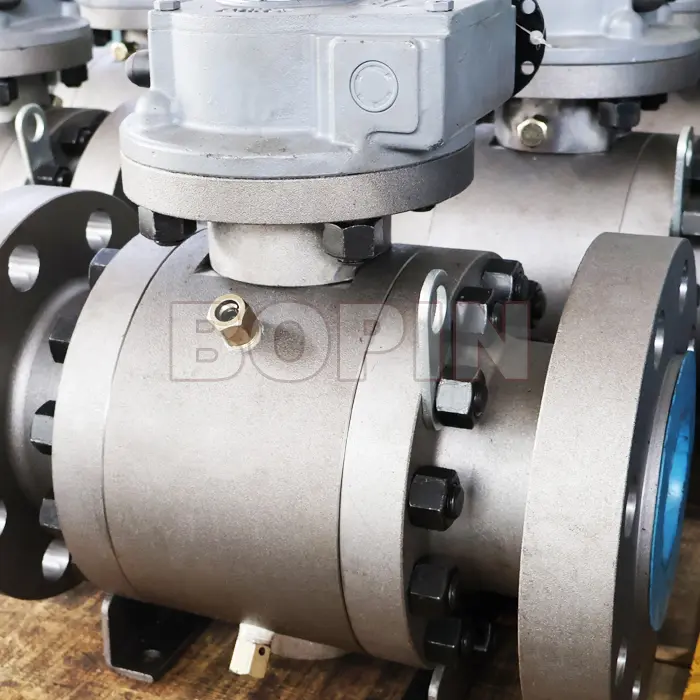

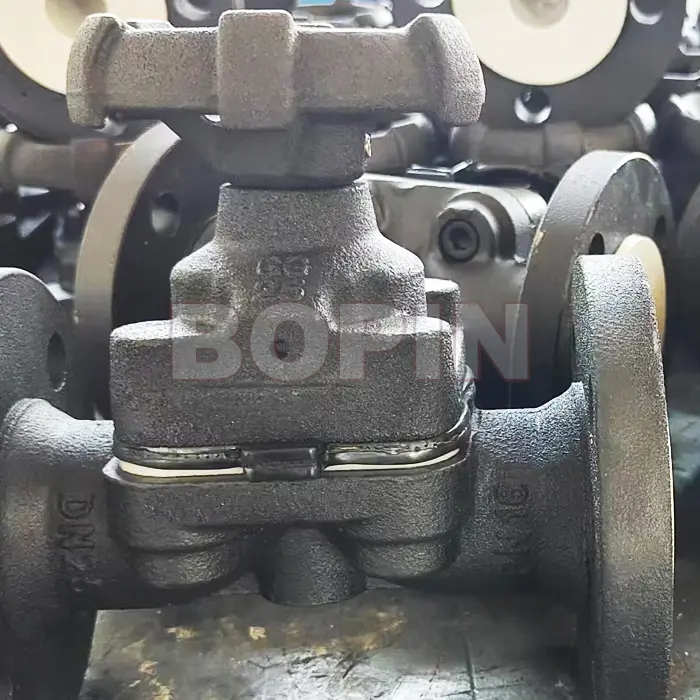

When it comes to sourcing resilient seated butterfly valves, finding a reliable supplier is crucial for ensuring operational efficiency and reliability. BOPIN VALVE stands out as an industry leader, offering tailored solutions that meet specific customer needs in terms of material, size, pressure rating, and specialized applications. Whether you're in the oil and gas sector, water treatment, or any industry requiring fluid control, BOPIN VALVE can provide you with high-quality valves designed for optimal performance. Choosing the right butterfly valve is essential for maximizing system efficiency. With BOPIN VALVE's bespoke design services, customers can expect valves that align perfectly with their operational requirements. This level of customization not only enhances functionality but also contributes to long-term cost savings by minimizing repair and replacement needs. As a global supplier, BOPIN VALVE is committed to supporting clients in achieving their goals through improved product reliability and efficiency. Incorporating these resilient seated butterfly valves into your operations can significantly reduce maintenance downtime and improve process safety. BOPIN VALVE leverages advanced manufacturing techniques to produce valves that withstand the rigors of various applications while maintaining peak performance. Purchasing from a trusted supplier like BOPIN VALVE ensures that you receive durable, reliable, and efficient products that will support your operations for years to come.

Quick Tips To Resilient Seated Butterfly Valve Application Supplier

| Parameter | Description | Material Options | Temperature Range | Pressure Rating |

|---|---|---|---|---|

| Body Type | Type of construction, determines the hydraulic performance. | Carbon Steel, Stainless Steel, PVC | -10°C to 150°C | 150 psi to 300 psi |

| Sealing Type | Method of sealing when valve is closed. | EPDM, NBR, PTFE | -10°C to 120°C | 100 psi to 200 psi |

| Actuation Method | Means of opening and closing the valve. | Manual, Electric, Pneumatic | -20°C to 140°C | 150 psi to 250 psi |

| End Connections | Types of connections to other piping. | Flanged, Welded, Threaded | -40°C to 200°C | 200 psi to 600 psi |

Champions of Resilient Seated Buttfly Valve Products Industry Giant

L

Lucas Harris

The products are durable and well-made. The after-sales support was efficient and informative.

31 May 2025

N

Noah Carter

Greatly pleased with the quality and durability! The after-sales service was quick and efficient.

08 May 2025

A

Abigail Phillips

Amazing quality and very professional service! I felt valued as a customer.

21 May 2025

L

Logan Edwards

Absolutely love the item! The support team was efficient and very knowledgeable.

06 July 2025

I

Isaac Turner

Exceptional quality! The representatives were very helpful and efficient in their service.

11 June 2025

H

Hunter Wright

The quality is second to none! The staff went out of their way to ensure I was satisfied.

18 May 2025