Why Choose Ductile Iron GGG40 Bellows Sealed Valves

1. Superior Mechanical Properties of GGG40 Ductile Iron

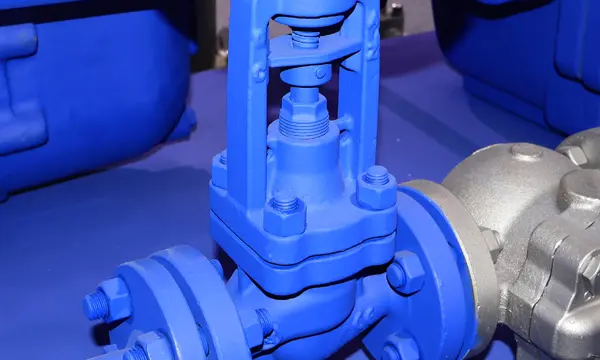

Ductile iron, specifically GGG40 (a grade of nodular cast iron), is known for its excellent mechanical properties. Unlike traditional gray cast iron, ductile iron has a microstructure that provides higher strength and flexibility. This is due to the inclusion of graphite nodules in the material, which significantly improves toughness, ductility, and resistance to cracking. The mechanical properties of GGG40 make it ideal for use in valves that operate under high pressure and temperature conditions.

The GGG40 material has:

High tensile strength: It can withstand substantial pressure without cracking, making it ideal for high-pressure applications.

Excellent impact resistance: Its toughness ensures that it can resist sudden impacts or vibrations in industrial systems.

Good wear resistance: This characteristic ensures that the valve will perform well over time, even in abrasive environments.

These properties are particularly important in industries like oil and gas, chemical processing, and power generation, where valves are exposed to extreme conditions.

2. Corrosion Resistance in Harsh Environments

In many industrial settings, valves are exposed to aggressive chemicals, salts, and other corrosive substances that can cause rapid wear and failure if the material is not resistant. Ductile iron GGG40 offers superior corrosion resistance compared to standard gray cast iron, making it an excellent choice for industries dealing with corrosive fluids.

While ductile iron is not completely immune to corrosion, it provides a better resistance than many other metals, especially in neutral and slightly acidic environments. Moreover, its resistance to saltwater corrosion makes it particularly useful in marine applications.

The addition of a bellows seal further enhances the corrosion resistance of the valve. Bellows seals are usually made of stainless steel or other corrosion-resistant alloys, which prevent leakage at the valve stem and protect the valve internals from external corrosive environments.

3. Leak-Free Operation with Bellows Seals

One of the most important considerations in valve selection is the ability to prevent leakage, especially when dealing with hazardous, toxic, or high-pressure fluids. Traditional valve seals, like stem packing, can degrade over time, leading to leaks and, in some cases, catastrophic failures. Bellows seals eliminate this risk.

Bellows-sealed valves are designed to create a tight seal around the valve stem, ensuring that there are no leaks along the stem. This is especially important in applications where toxic or highly pressurized fluids are involved. The flexible nature of the bellows allows the valve stem to move without compromising the integrity of the seal. This design minimizes the risk of fugitive emissions and enhances the safety and environmental sustainability of the operation.

The bellows seal system:

Prevents fluid leakage along the valve stem.

Reduces the need for frequent maintenance or re-packing.

Enhances the safety of operations, particularly in industries like chemical, pharmaceutical, or petrochemical manufacturing.

4. Durability and Long Service Life

Valves are subject to constant wear due to fluid flow, temperature fluctuations, and mechanical stress. Over time, this wear can lead to leaks, performance degradation, and, eventually, valve failure. The use of ductile iron GGG40 ensures that the valve can withstand these stresses for a longer period than other valve materials.

GGG40’s toughness and wear resistance ensure that the valve components, including the valve body, stem, and seals, will last longer, even under harsh operating conditions. This durability translates to fewer valve replacements, reducing both operational downtime and maintenance costs. As a result, the total cost of ownership for the valve is significantly lower in the long run.

5. Resistance to Fatigue and Thermal Expansion

Ductile iron is highly resistant to fatigue, which is a critical consideration for valves used in frequent cycling applications. In industries where valves are regularly opened and closed, the ability to withstand repeated mechanical stresses is essential. GGG40 material is capable of withstanding repeated mechanical stress without cracking, making it ideal for applications in power plants, refineries, and chemical plants.

Additionally, ductile iron has a relatively low thermal expansion coefficient, meaning it maintains its shape and dimensional integrity even when subjected to extreme temperature variations. This is particularly useful in applications involving high-temperature fluids, such as steam, where expansion and contraction can lead to valve distortion and leakage. The thermal stability of ductile iron ensures a reliable performance over a wide range of operating temperatures.

6. Ease of Maintenance and Replacement

Maintenance and downtime are critical factors for most industries. The combination of GGG40 ductile iron and bellows seals makes these valves low-maintenance compared to traditional valve designs. The bellows seal system eliminates the need for regular packing maintenance, which can be a time-consuming and costly process. Since the bellows are not subject to the same wear and tear as packing material, the valve’s performance is maintained longer without requiring frequent service.

Furthermore, if the valve does need to be repaired or replaced, ductile iron components are easier to work with compared to harder, brittle materials like cast steel. The material can be easily machined, allowing for quicker repairs and reducing the overall downtime of the system.

7. Flexibility and Versatility in Application

Ductile iron GGG40 bellows-sealed valves are versatile and can be used in a wide variety of applications, ranging from low-pressure systems to high-pressure, high-temperature environments. The combination of corrosion resistance, durability, and precise sealing makes these valves suitable for applications such as:

Chemical processing: Handling aggressive chemicals and preventing leaks of hazardous fluids.

Power generation: Controlling steam and water flow in power plants.

Water treatment: Regulating the flow of water or wastewater.

Marine and offshore: Ensuring reliable operation in saltwater environments.

Oil and gas: Managing high-pressure fluids safely and efficiently.

8. Cost-Effectiveness

While ductile iron GGG40 bellows-sealed valves might have a higher upfront cost compared to standard cast iron or other materials, their long service life and low maintenance requirements make them a cost-effective choice in the long run. The durability, safety, and performance advantages often outweigh the initial cost, especially in demanding industrial applications.

Additionally, the corrosion resistance and fatigue resistance of ductile iron GGG40 reduce the likelihood of costly valve failures, making it a smart investment for operations that cannot afford unplanned downtime.

Choosing ductile iron GGG40 bellows-sealed valves for industrial applications offers a range of benefits that enhance both the performance and safety of fluid handling systems. The combination of superior mechanical properties, corrosion resistance, leak-free operation, durability, and low maintenance make these valves a reliable solution for industries such as chemical processing, power generation, water treatment, and oil and gas. Their ability to withstand extreme conditions and provide long-lasting service makes them an excellent choice for demanding applications. By choosing ductile iron GGG40 bellows-sealed valves, industries can enjoy improved operational efficiency, reduced downtime, and a lower total cost of ownership.