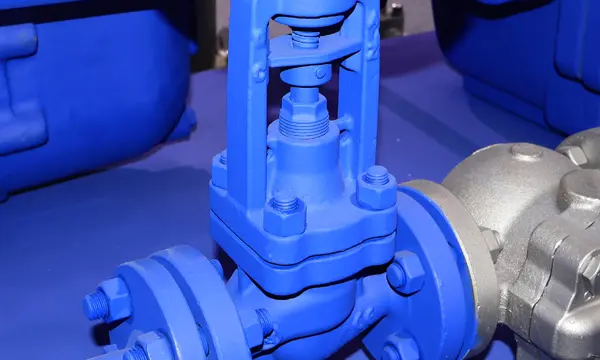

Order of DIN 3356 GS-C25 Bellows Sealed Globe Valves Secured for Russian Market

In a significant development for the industrial valve sector, a new order of DIN 3356 Flange End GS-C25 Bellows Sealed Globe Valves has been confirmed by BOPIN VALVE for delivery to the Russian market. This shipment reflects the continued demand for high-performance sealing technologies in critical industries such as oil and gas, power generation, and chemical processing across Russia. The order represents not only a commercial milestone for the manufacturer but also a reaffirmation of the growing reliance on advanced European valve standards in Russian industrial infrastructure.

According to industry sources, the order comprises a large quantity of bellows sealed globe valves ranging in sizes from DN 25 to DN 200, with pressure ratings of PN16, These valves are constructed from GS-C25 carbon steel and are fully compliant with the DIN 3356 standard.

The valves will be supplied with flange end connections in accordance with DIN EN 1092-1, ensuring smooth integration with existing pipeline systems in Russian facilities. The bellows sealing system is designed to guarantee zero fugitive emissions, a feature increasingly demanded in both domestic and export-oriented Russian industries due to tightening environmental requirements.

The end-users for this order include a mix of refineries, chemical plants, and district heating networks, all of which require reliable shut-off and control of steam, water, oil, and chemical flows.

The Russian industrial sector has been undergoing modernization, with emphasis on environmental compliance and operational safety. Traditional globe valves that rely solely on gland packing are more susceptible to leakage over time, especially in high-pressure and high-temperature applications.

The DIN 3356 GS-C25 Bellows Sealed Globe Valve addresses this challenge through:

Hermetically sealed design – Stainless steel bellows welded to the stem and bonnet eliminate emissions.

Backup safety – Graphite or PTFE gland packing as a secondary seal.

Durability – GS-C25 carbon steel body provides mechanical strength at pressures up to 40 bar and temperatures up to 425 °C.

Versatility – Suitable for steam, condensate, chemical, oil, and gas services.

By adopting these valves, Russian companies demonstrate a clear commitment to improving plant reliability, reducing maintenance cycles, and meeting stricter environmental regulations.

The order signals a growing demand for European-standard valves in Russia, particularly in industries with high safety and environmental requirements. Despite global economic challenges, Russia continues to invest in infrastructure upgrades, refinery modernization, and chemical processing expansion projects.

Industry analysts point out several implications of this order:

Sustainability Push – With Russia facing international scrutiny over emissions, industries are pressured to adopt leak-free technologies. Bellows Sealed Valves represent a practical step toward compliance.

Technological Transfer – The adoption of DIN-standard products indicates a preference for proven European engineering over lower-cost alternatives, highlighting quality as a key purchase factor.

Energy Sector Reliability – Russia’s vast oil and gas industry requires uninterrupted operation. Valves with longer service lives and reduced maintenance needs directly translate into lower downtime and higher efficiency.

End-User Industries

The valves in this order are earmarked for deployment across three major Russian sectors:

Oil & Gas Refineries

Control of feedstock, distillation streams, and steam systems.

Bellows sealed valves ensure no leakage of volatile hydrocarbons, enhancing worker and plant safety.

Chemical Processing Plants

Handling aggressive or hazardous media.

Bellows seals prevent toxic releases, aligning with international best practices.

District Heating and Power Generation

Russia’s extensive district heating networks rely heavily on steam and hot water control valves.

Bellows sealed valves offer long-term reliability, reducing frequent maintenance in remote installations.

The GS-C25 body material offers mechanical robustness while maintaining cost-effectiveness. Combined with precision machining, stellite seat options, and stainless steel bellows, the valve design ensures:

Tight shut-off to DIN leakage class A

Compliance with EN 12266 pressure testing

Backseat capability for repacking under pressure

Long bellows life-cycle (up to 10,000 operations tested)

This technical superiority explains why Russian buyers increasingly prefer these valves over conventional packed designs.

For manufacturers, securing a large-scale order from Russia represents both market penetration and strategic positioning. Russia’s industrial modernization drive creates opportunities for long-term supply contracts. Once installed, valves require ongoing spares and service support, ensuring continued business relationships.

From Russia’s perspective, sourcing valves built to DIN 3356 standards enhances equipment reliability while ensuring compliance with international safety and environmental frameworks—a key factor in exporting petrochemical products to global markets.

The successful completion of this order is expected to strengthen the position of DIN-standard valves in Russia’s industrial supply chain. As more plants modernize and adopt emission-free sealing technologies, demand for bellows sealed globe valves is set to grow steadily.

Industry insiders predict that this delivery could be followed by repeat orders for larger-diameter valves and customized solutions for Russia’s expanding energy and chemical projects.

The order of DIN 3356 Flange End GS-C25 Bellows Sealed Globe Valves for the Russian market highlights a decisive shift toward advanced sealing technologies and European engineering standards in critical industrial sectors. With rising environmental concerns, operational safety demands, and the need for reliable process control, the bellows sealed globe valve stands out as a preferred choice for Russia’s refineries, chemical plants, and district heating systems.

This milestone not only reinforces the value of GS-C25 bellows sealed globe valves in demanding service conditions but also underscores the strategic importance of aligning with global best practices in fluid control solutions.