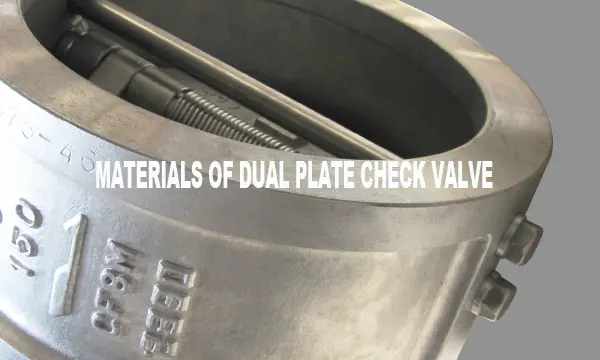

OPTIONAL MATERIALS OF DUAL PLATE CHECK VALVES

BOPIN starts with the selection of suppliers for castings and components, and proceed to each step including machining, assembly, and rigorous testing. We comprehensively control the details to ensure that every check valve meets the high standards expected by our customers, providing them with reliable solutions. We continuously research and improve our manufacturing processes, always keeping our product quality at the forefront of the industry. Providing you with high-end quality check valves is our unchanging goal.

The selection of materials for the components of BOPIN Dual Plate Check Valve is crucial to its performance and longevity. The body, discs, seat, seals, hinges, and shafts must all be made from materials that match the specific demands of the application, considering factors such as temperature, pressure, fluid type, and environmental conditions. By carefully choosing materials based on these factors, engineers can ensure that dual plate check valves operate reliably, efficiently, and with minimal maintenance, reducing downtime and increasing system safety and performance.

- Body

The body of a dual plate check valve is the outer casing that houses the internal mechanisms and is responsible for withstanding internal pressure and external forces. The material selection for the body is crucial to ensure the valve can handle the operating pressures and resist corrosion, erosion, and fatigue over time.

Common Optional Materials:

Carbon Steel (ASTM A216 WCB): Carbon steel is a popular material choice for valve bodies due to its strength, durability, and cost-effectiveness. It is suitable for applications where the fluid is non-corrosive or where the pressure and temperature are moderate. However, it has limited resistance to corrosion compared to other materials.

Stainless Steel (ASTM A351 CF8, CF8M): Stainless steel is the most commonly used material for the body in environments where corrosion resistance is required. Stainless steel grades such as CF8 (304) and CF8M (316) are popular due to their high resistance to corrosion from water, chemicals, and other corrosive substances. The material is also favored for high-temperature applications due to its strength at elevated temperatures.

Ductile Iron (ASTM A536): Ductile iron is an alternative to cast iron and provides better strength and wear resistance. It is used in applications where high mechanical strength is necessary but corrosion resistance is not as critical. This material is commonly found in larger valves used in water treatment plants.

Alloy Steel (ASTM A217 WC6, WC9): Alloy steels, such as WC6 and WC9, offer enhanced resistance to high temperatures and pressure. These materials are ideal for power plants and industries that handle high-temperature fluids, such as steam or hot oils.

Cast Iron (ASTM A126 Class B): Cast iron is a cost-effective choice for low-pressure, non-corrosive applications. It provides good strength but lacks the corrosion resistance of stainless steel or alloys. It is commonly used in water and wastewater applications where corrosion is not a major concern.

- Discs (Plates)

The discs or plates of a dual plate check valve are critical components that allow the valve to function properly. They pivot to open or close depending on the direction of flow. The material used for the discs must be durable, lightweight, and resistant to both wear and corrosion, as the discs experience significant mechanical stress and wear due to the flow medium.

Common Optional Materials:

Stainless Steel (ASTM A240 304, 316): Stainless steel is widely used for discs due to its excellent strength, corrosion resistance, and ability to withstand harsh environments. Type 316 stainless steel (CF8M) is preferred in marine or chemical applications because of its superior resistance to corrosion.

Nickel Alloys (Monel, Inconel): Nickel-based alloys such as Monel (NiCu) and Inconel (NiCr) offer exceptional strength and resistance to both high temperatures and corrosive environments. These alloys are commonly used in industries dealing with extreme conditions, such as the chemical and petrochemical industries.

Bronze (C95400): Bronze is used in some applications for its superior corrosion resistance in seawater and other harsh fluids. It is commonly used in marine applications due to its ability to withstand saltwater corrosion.

Aluminum Bronze (C63000): Aluminum bronze is a high-strength material that offers excellent corrosion resistance, particularly in marine and offshore applications. It also has good resistance to wear and erosion.

Carbon Steel (ASTM A105): Carbon steel can be used for disc materials in less demanding applications, particularly when the fluid being handled is not corrosive. It is a cost-effective material choice for general applications.

- Seat

The seat is the component where the disc seals against when the valve closes. The material of the seat must have excellent wear and erosion resistance, as well as good sealing properties to prevent leakage. The material should also be compatible with the fluid being transported.

Common Optional Materials:

Stainless Steel (ASTM A351 CF8M): Stainless steel is a popular choice for valve seats due to its strength and corrosion resistance. It is especially useful in high-performance applications, as it ensures a tight seal and resists corrosion over time.

Hardened Steel (HRC 50-60): Hardened steel is often used for seats in applications where the flow medium is abrasive or where the valve will experience frequent cycling. The hardness provides wear resistance, ensuring the valve maintains its sealing capability over time.

Seat Inserts (PFA, PTFE, Elastomers): For applications involving aggressive chemicals or high temperatures, soft materials such as PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), or elastomers like Viton or nitrile may be used for seat inserts. These materials provide excellent sealing performance and resistance to chemicals, oils, and high temperatures.

Ceramic or Cermet Coatings: In environments where high abrasion is a concern, ceramic or cermet (a combination of ceramic and metal) coatings may be applied to valve seats. These coatings offer enhanced wear resistance while maintaining corrosion protection.

- Hinges &Shafts

The hinge mechanism is a key component in the operation of a dual plate check valve, allowing the plates to pivot open or closed. Hinges and shafts are subjected to mechanical stress and must be made from materials that offer high tensile strength and resistance to wear and corrosion.

Common Optional Materials:

Stainless Steel (ASTM A240 316L): Stainless steel is commonly used for hinge pins and shafts because of its excellent mechanical properties and resistance to corrosion, especially in marine or chemically aggressive environments. The low-carbon version, 316L, is preferred for applications involving chlorine, brine, or seawater.

Alloy Steel (ASTM A182 F11, F22): Alloy steel is used when additional strength is required. This material is well-suited for high-pressure applications and can withstand high mechanical stresses.

Bronze (C95400): Bronze, particularly high-strength grades like C95400, is another material option for hinges and shafts, providing excellent resistance to corrosion and wear in marine and offshore applications.

- Seals and Gaskets

Seals and gaskets are vital for preventing leaks when the valve is closed. The materials selected must provide a tight seal while being resistant to temperature fluctuations, pressure changes, and chemical exposure.

Common Optional Materials:

PTFE (Polytetrafluoroethylene): PTFE is widely used for seals due to its outstanding chemical resistance, high-temperature stability, and low friction properties. It is commonly used in valves that handle aggressive chemicals, oils, or gases.

Viton (FKM): Viton is a synthetic rubber that offers excellent resistance to high temperatures and chemicals. It is commonly used in the chemical and oil industries where aggressive fluids are present.

Nitrile (Buna-N): Nitrile is an economical sealing material, widely used in applications where the fluid is petroleum-based. It offers good resistance to oils, fuels, and other hydrocarbons.

EPDM (Ethylene Propylene Diene Monomer): EPDM seals are commonly used in applications involving steam, water, and other polar liquids. They are resistant to weathering, ozone, and high temperatures, but are not suitable for petroleum-based products.