IMPORTANCES OF FLANGE HOLE COUNTERSUNKING FOR LOW PRESSURE & SMALL SIZE FLANGED VALVES.

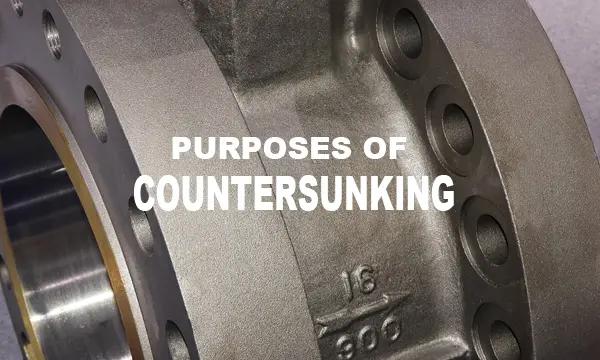

Dimpling is a process of machining countersunk holes on flanges to ensure a good fit between bolt heads or nuts and the flange surface, avoiding stress concentration. For low-pressure and small-diameter valves, the requirements for countersunking processing need to be analyzed in conjunction with specific standards and application scenarios.

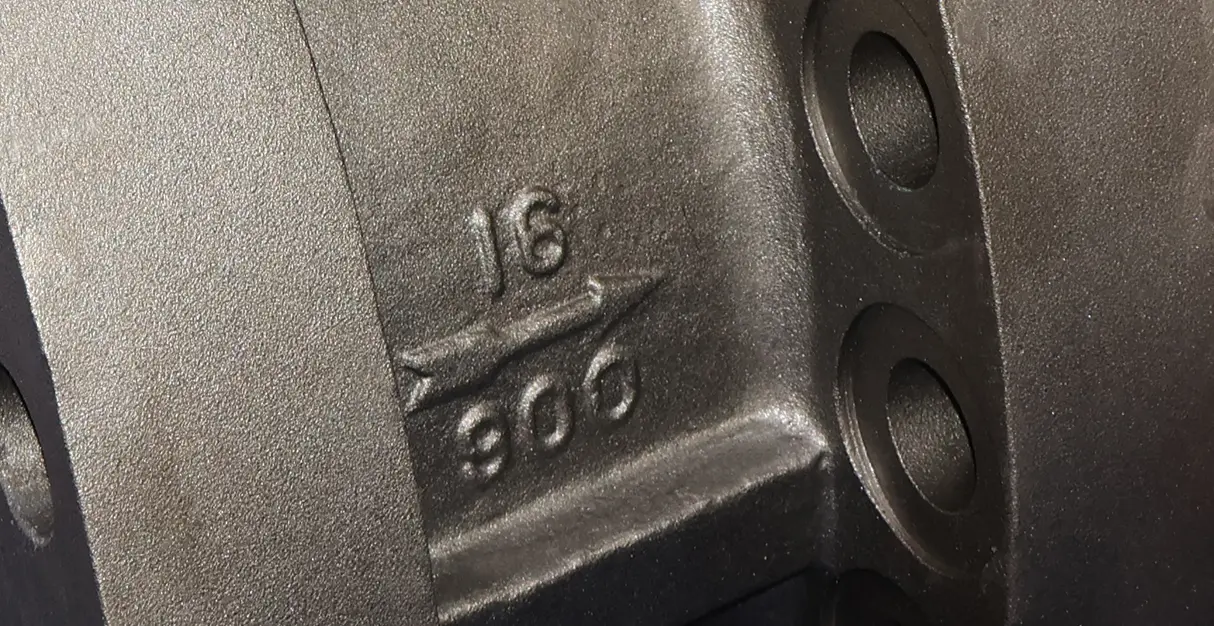

In terms of standard applicability, the MSS standard clearly applies to flange countersunking of Industrial Valves, including bronze, cast iron, malleable iron, or steel integral cast valves, covering bolts with nominal sizes ranging from% inches to 3% inches. This means that even for small-diameter valves (such as valves with smaller nominal sizes), as long as flange connections are involved and product standards require it, countersunking may still need to follow such specifications to ensure the reliability of bolted connections.

Processing limitations and wall thickness requirements are key factors. Dimpling processing will cut into the neck of the mating flange or valve housing, so the wall thickness after processing must not be less than the minimum wall thickness specified in the corresponding standard. For low-pressure and small-diameter valves, the material wall thickness is usually thin, which may impose stricter restrictions on countersunking processing, such as controlling the countersunking diameter and different axial deviations to avoid weakening the structural strength of the valve.

In low-pressure applications, although the pressure load is low, countersunking still helps to improve the sealing and durability of the connection, reducing the risk of leakage caused by bolt loosening or stress concentration. For small-diameter valves (such as those below DN50), if the design involves flange connections and frequent disassembly, countersunking may be used to facilitate bolt operation, but the impact of machining on thin-walled structures needs to be balanced.

In actual installation, for pipelines with low temperature or special working conditions, it is recommended to connect short pipes near bends or tees before welding flanges to leave room for cold insulation thickness and loading and unloading space. This approach may indirectly involve countersunking, but it focuses more on pipeline flexibility and cold insulation structure design rather than directly addressing valve countersunking requirements.

The requirements for low-pressure and small-diameter valves in flat processing mainly depend on product standards, flange dimensions, and structural strength constraints. Small caliber valves require special attention to meeting the minimum wall thickness during processing due to their thin wall thickness. Low pressure environments may reduce the strict requirements for countersunking depth, but standard consistency still needs to be observed.

In summary, countersunking of flange surfaces is a mechanical machining process that uses countersunking drills to cut the surface of the workpiece, forming a flat or countersunk structure. This process plays a key role in flange processing, mainly reflected in the following aspects.

A: Provide a flat assembly support surface

The core function of countersunking is to cut a flat surface perpendicular to the hole axis around the flange hole, providing a stable support surface for bolts, nuts, or other connecting components. This flat surface can effectively avoid bias and looseness during assembly, ensuring the reliability and sealing of the connection, especially in situations that bear large loads or vibrations (such as engine cylinder heads, gearbox housings, etc.).

B: Improve connection accuracy and sealing performance

Through countersunking treatment, the surface roughness and perpendicularity of the flange plane are optimized, reducing the risk of stress concentration or leakage caused by uneven surfaces. For example, in bolted connections, a flat countersunk surface can ensure uniform distribution of preload force, thereby improving the overall sealing performance and fatigue life of the structure.

C: Adapt to different structural requirements and mass production

The countersunking process can be adapted to structural requirements such as countersunking and step holes by adjusting the countersunking type (such as flat bottom, cone, or composite), and can achieve efficient sequential machining on CNC machines, reducing tool wear and improving consistency. For the application of large flanges, rocker drilling machines and other equipment, optimizing the cutting path can also reduce tool marks and further ensure processing quality.

D: Optimize processing efficiency and surface quality

Modern countersunking technology reduces cutting resistance and vibration, improves surface smoothness and machining efficiency through the design of split cutting tools, depth control devices, and chip removal improvements (such as gas collectors). In the reverse countersunking process, reverse machining of bolt hole end faces can also be achieved, further expanding its applicability in complex flange structures.