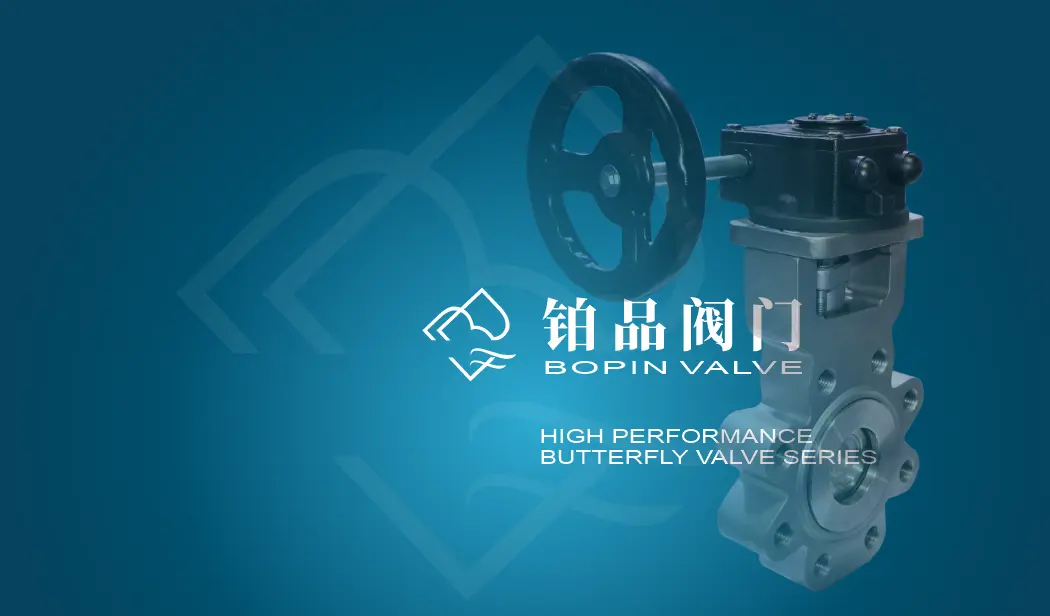

How to Identify Double Eccentric High-Performance Butterfly Valves by Appearance

Double eccentric high-performance Butterfly Valves are an advanced type of valve commonly used in industries where high performance, reliability, and tight shut-off are required. These valves are characterized by their unique design, which includes a double offset mechanism, setting them apart from standard butterfly valves. Understanding their appearance and identifying features is crucial for engineers, operators, and maintenance personnel to ensure correct application and operation.

1. Basic Overview of a Double Eccentric Butterfly Valve

A butterfly valve is a quarter-turn valve used to regulate or isolate the flow of fluids through a pipeline. The double eccentric design refers to the positioning of the valve's shaft and disc, where the shaft is positioned off-center from the valve body and the disc is offset from the valve's axis. This design reduces friction, improves sealing, and increases the lifespan of the valve.

High-performance butterfly valves typically have features that make them suitable for high-pressure, high-temperature, or corrosive fluid applications. They are often made from durable materials like stainless steel, cast iron, or alloys, and they provide superior performance compared to traditional single eccentric or resilient-seated butterfly valves.

2. Key Identification Features

a. Double Eccentric Design

The most prominent feature of a double eccentric butterfly valve is the offset design. This includes:

First Eccentricity: The disc is offset from the centerline of the valve body, which reduces the contact area between the disc and the valve seat during operation.

Second Eccentricity: The valve shaft itself is positioned offset, creating an additional advantage in terms of reducing wear and tear and improving the tightness of the shut-off.

This double eccentric design minimizes the mechanical forces exerted on the valve components during operation, leading to a more efficient and long-lasting valve.

b. Valve Disc Shape

In high-performance butterfly valves, the valve disc tends to have a more precise and streamlined shape compared to standard butterfly valves. The disc often has a "cambered" or "conical" profile, making it easier for the valve to move smoothly and reducing the resistance in the flow path. This streamlined disc profile helps achieve better shutoff performance and control, especially under high-pressure conditions.

Additionally, the disc is usually designed with a thin edge that enhances sealing capabilities, making it less likely to distort or damage the valve seat.

c. Valve Body and Construction

High-performance butterfly valves typically have a metal-bodied design, made of materials such as stainless steel, alloy steel, or bronze, designed for extreme operating conditions. The valve body will typically appear heavier and more robust than that of standard butterfly valves. The valve will have a smooth, streamlined design, minimizing flow resistance and allowing for higher flow rates and more efficient operation.

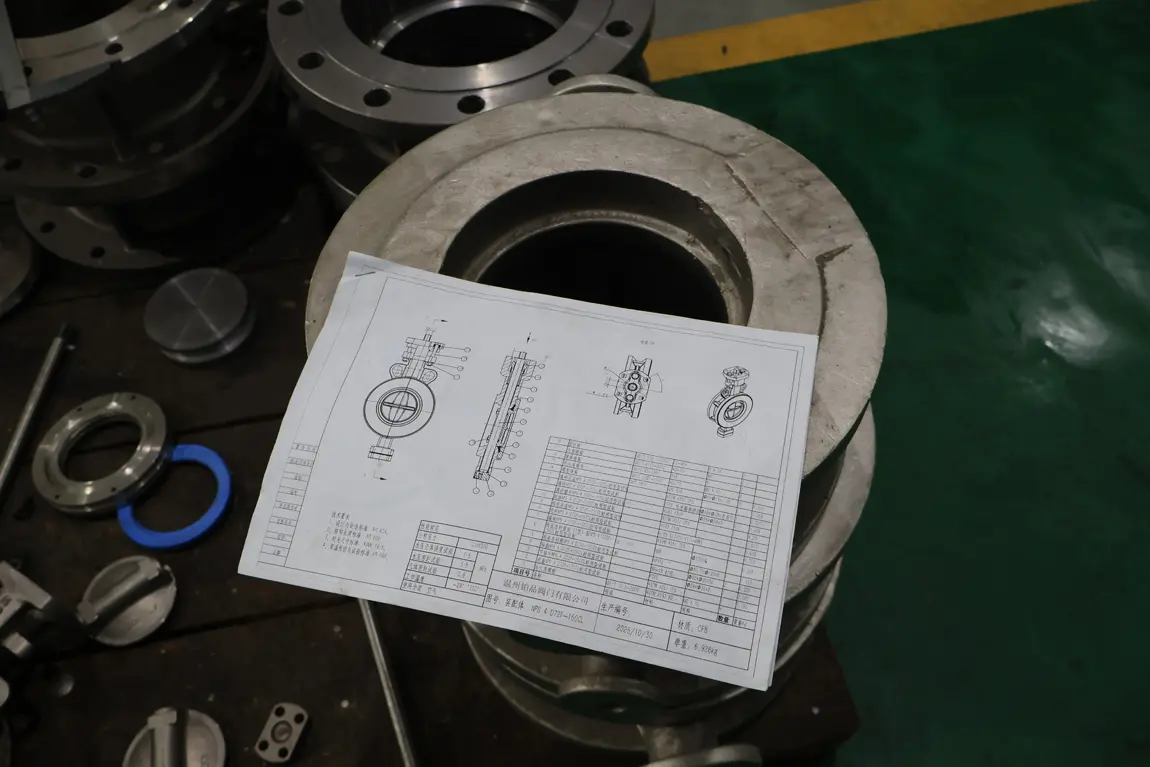

The body is often cast, and reinforced flanges or bolting patterns are visible, as these valves are built to handle high-pressure and high-temperature applications.

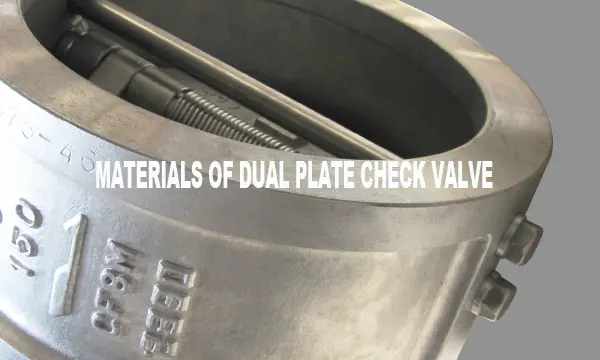

d. Seating System

The seat of a double eccentric high-performance butterfly valve is typically metal-seated, which offers superior sealing capabilities and resistance to wear, particularly in high-temperature or abrasive environments. The seating material may be made from metals such as stainless steel or alloy, providing better performance than the rubber or elastomer seats seen in lower-end butterfly valves.

The seat is often designed to be self-adjusting, ensuring a tighter seal as the valve operates over time. The pressure applied by the eccentric design ensures that the disc compresses the seat material uniformly, ensuring a leak-proof shut-off.

e. Actuation Mechanism

High-performance butterfly valves are often equipped with actuators that can be pneumatic, electric, or hydraulic. The actuation system is typically more robust and designed for precise control under challenging conditions. The actuator will often be visibly larger and more sophisticated than the manual handwheel used in standard butterfly valves.

The actuator is usually attached to the valve shaft, and in some designs, you may notice gear mechanisms or pneumatic motors visible at the top or side of the valve, allowing for fine-tuned adjustments and quicker valve cycling.

f. Stem and Shaft Design

The valve stem and shaft in a double eccentric high-performance butterfly valve are usually stronger and more durable than those found in standard butterfly valves. The shaft is designed to support the eccentric mechanism and is often made of stainless steel or other corrosion-resistant materials. The shaft and stem design are critical in providing smooth rotation and preventing excessive wear.

g. Flange and Connections

The flange connections of a high-performance butterfly valve are heavy-duty and reinforced, designed to handle higher pressure and temperature ratings. The bolt holes around the flange are often larger and may be marked with pressure ratings or size specifications for ease of installation.

Some models also feature integrated sealing gaskets or O-rings that improve the tightness of the valve when it is installed in a pipeline. These gaskets are usually made of high-performance materials, such as PTFE, for greater resistance to thermal cycling and chemicals.

3. Physical Size and Design Considerations

Larger Valve Sizes: Double eccentric butterfly valves tend to be larger in size compared to standard butterfly valves, especially when designed for high-performance applications. They are often seen in pipeline sizes ranging from 2" to 48" or more. The larger the valve, the more robust the components will appear.

Thicker Wall Construction: Given their high-performance nature, these valves typically have thicker walls and may include reinforced ribs along the body to prevent distortion under high operating pressures.

4. Additional Design Features

a. Flow Control

Double eccentric high-performance butterfly valves are often used where precise flow control is required. The valve’s appearance will reflect this with more refined control mechanisms in place, including actuator systems that allow for fine control over the valve’s position.

b. Valve Position Indicator

In high-performance applications, a position indicator is often visible on the valve to show whether the valve is open, partially open, or closed. This is important for operators to visually monitor the valve’s status, especially in automated systems.

5. Differentiating from Other Types of Butterfly Valves

Compared to standard butterfly valves, the double eccentric high-performance version can be identified by the following features:

Offset Disc: A key feature is the eccentric placement of the disc, which reduces friction during operation and improves sealing.

Thicker Construction: The high-performance valve will be bulkier, with thicker walls and stronger materials.

Metal Seat Design: Unlike resilient-seated butterfly valves, which have rubber or elastomer seats, these valves use metal seats for better sealing and performance at higher temperatures and pressures.

Of course, the aforementioned description involves highly specialized knowledge. If a layperson were to visually inspect the appearance, they would essentially be looking at the position of the sealing ring. If the sealing ring is fixed to the valve plate with screws, and the screws are visible through the valve plate, then it is a three-eccentric butterfly valve. If the sealing ring is on the valve body, and the valve plate appears bare without screws, then it is a double-eccentric high-performance butterfly valve.