0102030405

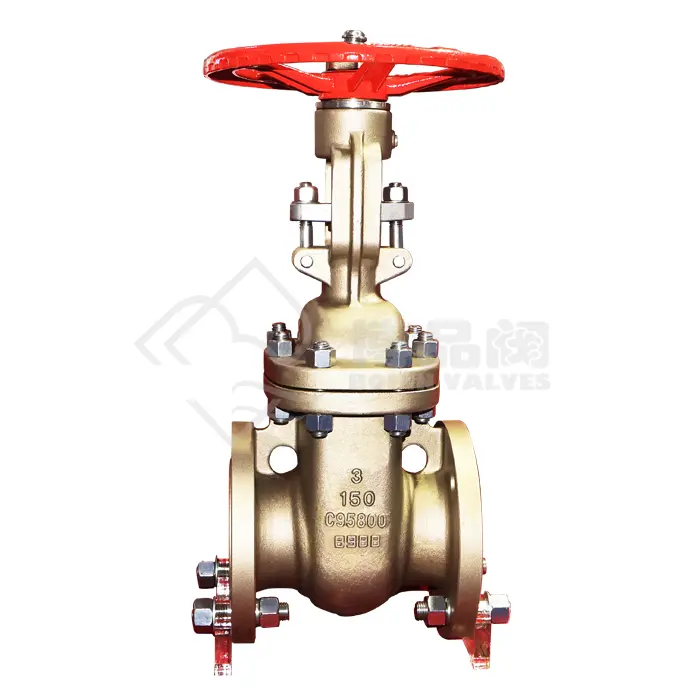

MONOFLANGE DBB GAUGE VALVE

API Standard: DBB Valve Definition and Features

What is a Double Block and Bleed (DBB) Valve?

A Double Block and Bleed (DBB) valve is a critical component in applications where safety and leak prevention are paramount. The DBB valve system is designed to isolate a portion of a pipeline or system by having two separate sealing points, with a venting or bleeding option in between. The two isolation points ensure that even if one seal fails, the other seal will prevent fluid leakage. The vent or bleed feature allows for safe and controlled discharge of any trapped fluid, ensuring that the system remains safe during maintenance, commissioning, or depressurization procedures.

In a DBB gauge valve, this design is used to isolate a pressure gauge or measurement device while also allowing for the safe venting of any trapped fluid, preventing corrosion, pressure buildup, or hazardous leaks. The vent port enables technicians to safely release pressure from the instrument without interfering with the main system.

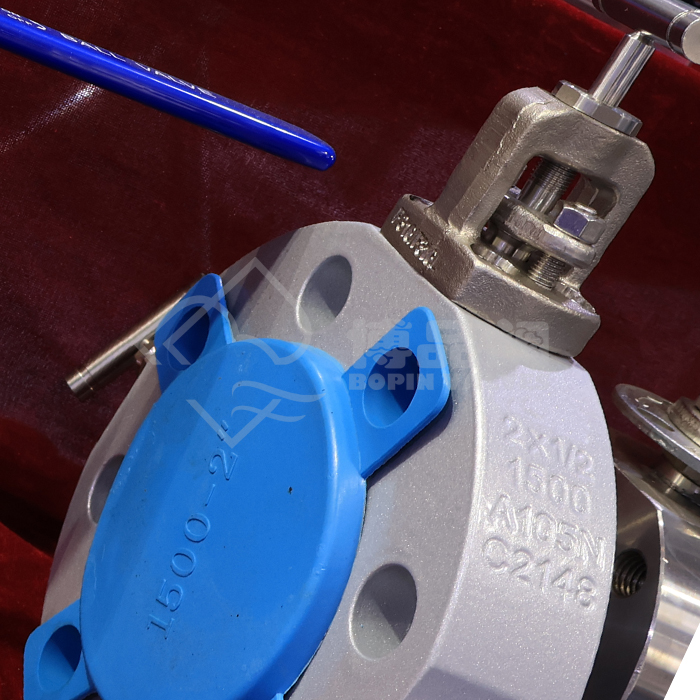

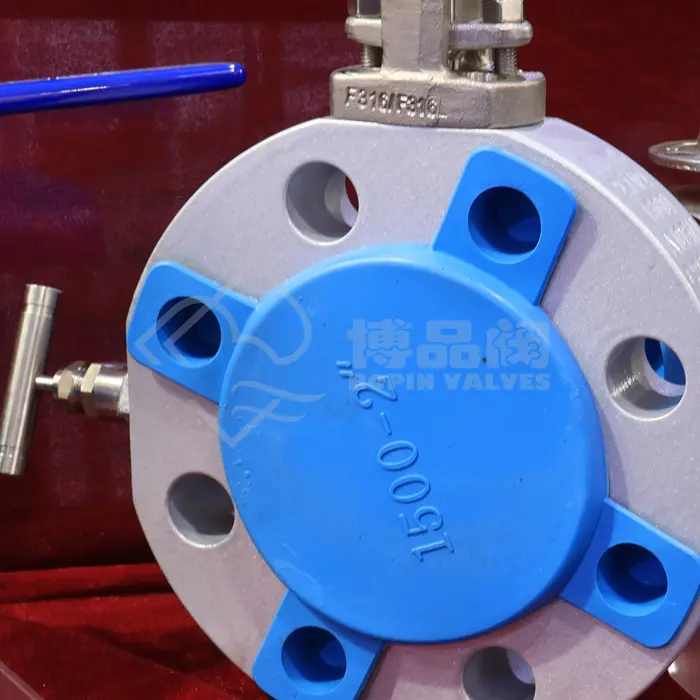

Mono Flange Design

The mono flange design refers to a valve assembly that integrates multiple components, including the valve body, into a single, compact flange unit. This eliminates the need for multiple flanges, seals, and gaskets in the piping system, making the installation process more efficient and reducing the chances of leakage points. The mono flange is designed to attach directly to the pipeline or equipment, offering a streamlined installation.

Some of the benefits of the mono flange design include:

Space Saving: Mono flange valves save space in tight or compact installations, providing a more compact solution compared to traditional multi-piece valve assemblies.

Reduced Leak Paths: By eliminating the need for multiple connections and gaskets, the mono flange design significantly reduces the number of potential leak paths in a system.

Easier Installation: Mono flange valves simplify the installation process by reducing the number of individual components, leading to quicker and less complex setup.

Applications of the API Mono Flange DBB Gauge Valve

DBB gauge valves are essential in many industries where fluid containment and monitoring are critical. Below are some of the key applications for this type of valve:

1. Oil & Gas Industry

The oil and gas industry relies on accurate pressure measurements and isolation systems to maintain safe operation. The DBB gauge valve is used to isolate pressure gauges and monitoring instruments in pipelines, wellheads, and other critical equipment. The double block feature ensures that the gauge remains isolated from the main system during maintenance or failure, while the bleed port allows for safe pressure relief.

2. Petrochemical and Chemical Plants

In chemical plants, managing hazardous and corrosive fluids is essential for both safety and operational efficiency. The DBB gauge valve provides a means to isolate and protect pressure gauges used in hazardous environments. It ensures that even in the event of a leak, the system remains isolated, preventing catastrophic damage to the entire plant.

3. Power Generation

Power plants, especially nuclear, coal, and natural gas facilities, use pressure gauges and instrumentation to monitor the various components of their systems, such as steam lines, boilers, and turbines. The DBB gauge valve provides the necessary isolation to these gauges, ensuring accurate readings while protecting operators from dangerous conditions during maintenance or servicing.

4. Water Treatment and Distribution Systems

Water treatment facilities use pressure gauges and monitoring equipment to control flow, pressure, and chemical dosing systems. The DBB gauge valve is essential for safely isolating instruments during maintenance, ensuring that any trapped fluids are safely vented to prevent damage to the system and equipment.

5. Pharmaceuticals and Food Processing

In the pharmaceutical and food processing industries, where hygiene, safety, and precision are critical, the DBB gauge valve offers an efficient method for isolating pressure instruments. It allows for precise pressure control and protection of the instruments, while minimizing any risk of contamination or failure.

Key Features of the API Mono Flange DBB Gauge Valve

Dual Isolation: The valve features two sealing points for double isolation, ensuring that pressure or hazardous fluids are securely contained within the system.

Bleed Port: The integrated bleed port allows technicians to safely release any trapped pressure from the gauge during maintenance or servicing.

Compact Design: The mono flange design reduces the number of components, simplifying installation and reducing the risk of leaks.

Pressure Rating: Designed to withstand high pressures, making it suitable for high-pressure systems and critical applications.

Leakage Prevention: The double block feature ensures that if one seal fails, the second seal will maintain isolation, preventing any leaks.

Enhanced Safety: The DBB capability ensures that hazardous fluids or gases are safely contained and vented, reducing the risk of exposure or system failure.

Easy Maintenance: The design allows for easy maintenance and servicing, ensuring long-term reliability and operational safety.

Installation and Maintenance Considerations

The installation of a mono flange DBB gauge valve requires careful attention to ensure the system operates safely and efficiently. When installing, it is essential to:

Ensure that the valve is installed with the correct orientation and flow direction.

Verify that the valve is adequately sealed and torqued to the correct specifications to prevent any leaks.

Regularly inspect the valve for signs of wear, corrosion, or damage to ensure long-term reliability.

Follow the manufacturer's recommended maintenance schedules, including cleaning the vent/bleed ports and replacing seals if necessary.