0102030405

LUGGED STAINLESS STEEL HIGH PERFORMANCE BUTTERFLY VALVES

1. What is a Lugged Stainless Steel High-Performance Butterfly Valve?

A butterfly valve is a flow control device that regulates the flow of fluid through a pipe by using a rotating disc. The term “butterfly” refers to the appearance of the valve’s disc when it is in the open position, resembling the wings of a butterfly. A high-performance butterfly valve is engineered to withstand higher pressures, temperatures, and demanding flow control applications. The lugged design refers to the valve's method of installation, where the valve body is equipped with threaded lugs on each side of the valve. These lugs allow the valve to be installed between two flanged pipe sections, providing a robust and secure connection.

The stainless steel construction makes these valves resistant to corrosion, ensuring a long operational life, especially in environments where harsh or corrosive fluids are transported.

The stainless steel construction makes these valves resistant to corrosion, ensuring a long operational life, especially in environments where harsh or corrosive fluids are transported.

2. Construction of the Lugged Stainless Steel High-Performance Butterfly Valve

The construction of a Lugged Stainless Steel High-Performance Butterfly Valve consists of several key components, each of which plays an important role in the valve's operation and durability:

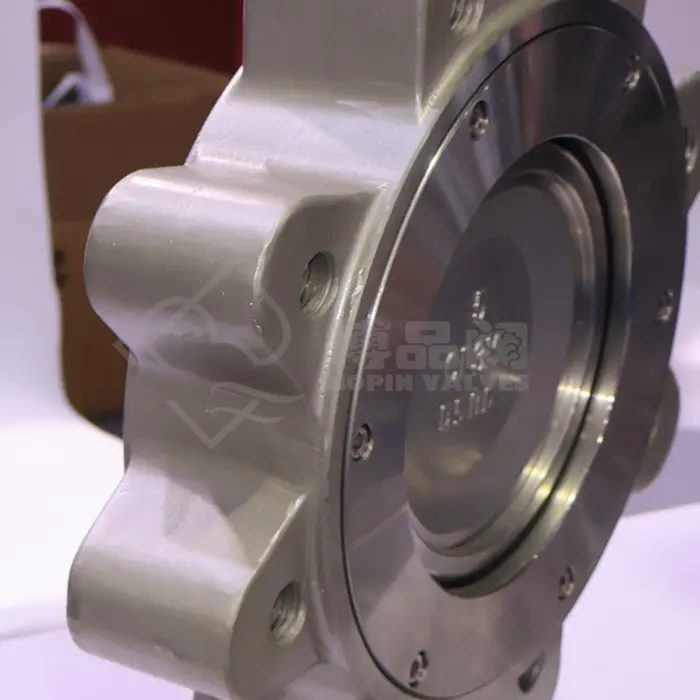

2.1. Valve Body (Lugged Design)

The body of the valve is made from stainless steel, which is known for its excellent resistance to corrosion, high temperatures, and mechanical wear. The lugged design allows for easier installation and removal of the valve from the piping system, making it ideal for applications where maintenance is frequent or the valve needs to be isolated without disassembling the entire piping system.

Lugged Design: The lugged feature allows the valve to be mounted between two flanges. The lugs are threaded holes in the body that allow for bolts to securely attach the valve to the system, without the need for a separate flange between the valve and pipe.

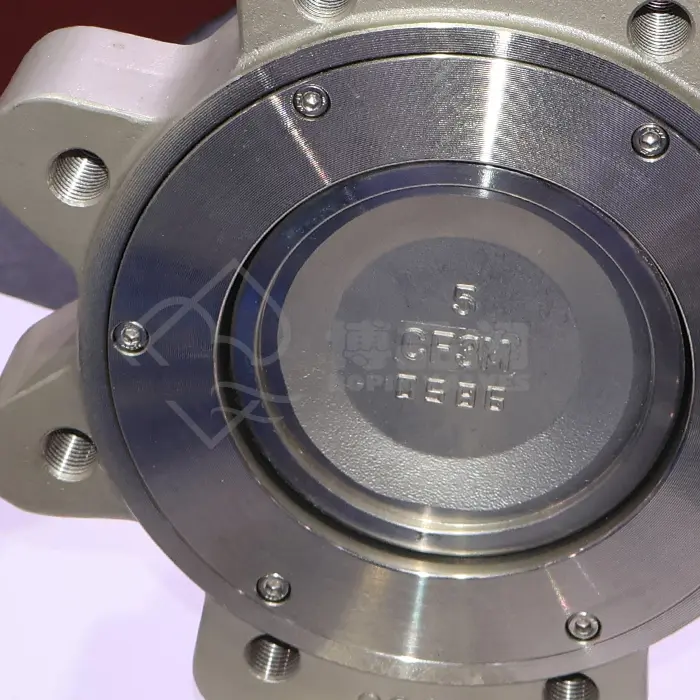

2.2. Disc

The disc is the central element of the butterfly valve, responsible for controlling the flow of fluid. The disc is attached to a shaft and rotates to either allow or block the passage of fluid. In high-performance butterfly valves, the disc is designed to ensure tight shutoff with minimal leakage.

The disc is typically constructed from stainless steel or other durable alloys, ensuring that it remains strong and resistant to erosion and corrosion, even under extreme conditions.

2.3. Shaft

The shaft connects the disc to the actuator and is the element that allows the valve to rotate. The shaft is usually made from high-strength stainless steel, ensuring that it can withstand the mechanical stresses during operation. It is designed to ensure smooth operation of the valve and prevent wobbling or misalignment.

2.4. Seat

The seat is a critical component of the butterfly valve. It provides a seal around the valve disc to prevent leaks. High-performance butterfly valves often use elastic or polymer-based seats that provide a reliable seal even under high pressures and temperatures. The seat material can vary depending on the application, with options including elastomers, PTFE, or metal.

2.5. Actuator (Manual or Automated)

The actuator is responsible for rotating the shaft and the valve disc. Manual actuators can be handwheels, gear operators, or levers, whereas automated actuators may include electric, pneumatic, or hydraulic systems. The actuator choice depends on the application’s requirements, such as speed, precision, and control.

2.1. Valve Body (Lugged Design)

The body of the valve is made from stainless steel, which is known for its excellent resistance to corrosion, high temperatures, and mechanical wear. The lugged design allows for easier installation and removal of the valve from the piping system, making it ideal for applications where maintenance is frequent or the valve needs to be isolated without disassembling the entire piping system.

Lugged Design: The lugged feature allows the valve to be mounted between two flanges. The lugs are threaded holes in the body that allow for bolts to securely attach the valve to the system, without the need for a separate flange between the valve and pipe.

2.2. Disc

The disc is the central element of the butterfly valve, responsible for controlling the flow of fluid. The disc is attached to a shaft and rotates to either allow or block the passage of fluid. In high-performance butterfly valves, the disc is designed to ensure tight shutoff with minimal leakage.

The disc is typically constructed from stainless steel or other durable alloys, ensuring that it remains strong and resistant to erosion and corrosion, even under extreme conditions.

2.3. Shaft

The shaft connects the disc to the actuator and is the element that allows the valve to rotate. The shaft is usually made from high-strength stainless steel, ensuring that it can withstand the mechanical stresses during operation. It is designed to ensure smooth operation of the valve and prevent wobbling or misalignment.

2.4. Seat

The seat is a critical component of the butterfly valve. It provides a seal around the valve disc to prevent leaks. High-performance butterfly valves often use elastic or polymer-based seats that provide a reliable seal even under high pressures and temperatures. The seat material can vary depending on the application, with options including elastomers, PTFE, or metal.

2.5. Actuator (Manual or Automated)

The actuator is responsible for rotating the shaft and the valve disc. Manual actuators can be handwheels, gear operators, or levers, whereas automated actuators may include electric, pneumatic, or hydraulic systems. The actuator choice depends on the application’s requirements, such as speed, precision, and control.

3. Working Principle

The Lugged Stainless Steel High-Performance Butterfly Valve operates based on the simple principle of a rotating disc. Here is how it works:

Open Position: When the actuator rotates the disc, it is positioned parallel to the flow path, allowing fluid to pass through the valve. In the open position, the valve offers minimal resistance to the fluid flow.

Shutoff: When the actuator turns the disc 90 degrees to the closed position, the disc is perpendicular to the flow, blocking the fluid from passing through the valve. The elastic seat material creates a tight seal between the valve disc and the valve body, preventing leakage.

Flow Control: By adjusting the position of the disc, the valve can provide partial control over the flow rate. This feature is particularly useful in applications where precise flow regulation is required.

The lugged design enhances the valve's versatility in installation, allowing it to be quickly isolated or replaced without needing to remove the entire pipeline. It also reduces the risk of valve damage during maintenance, as the flanged design offers better support.

Open Position: When the actuator rotates the disc, it is positioned parallel to the flow path, allowing fluid to pass through the valve. In the open position, the valve offers minimal resistance to the fluid flow.

Shutoff: When the actuator turns the disc 90 degrees to the closed position, the disc is perpendicular to the flow, blocking the fluid from passing through the valve. The elastic seat material creates a tight seal between the valve disc and the valve body, preventing leakage.

Flow Control: By adjusting the position of the disc, the valve can provide partial control over the flow rate. This feature is particularly useful in applications where precise flow regulation is required.

The lugged design enhances the valve's versatility in installation, allowing it to be quickly isolated or replaced without needing to remove the entire pipeline. It also reduces the risk of valve damage during maintenance, as the flanged design offers better support.

4. Advantages of Lugged Stainless Steel High-Performance Butterfly Valve

4.1. Corrosion Resistance

The use of stainless steel ensures that these valves can withstand corrosive environments, making them ideal for applications involving aggressive fluids like chemicals, wastewater, or saline water. The stainless steel also ensures longer valve life, reducing the need for frequent replacements.

4.2. High Performance at Elevated Temperatures and Pressures

High-performance butterfly valves are designed to handle extreme conditions, including high-pressure and high-temperature systems. The valve’s design and material choice make it ideal for steam, gas, and other challenging applications that require robust performance.

4.3. Compact and Lightweight

Compared to other types of valves, such as gate or globe valves, butterfly valves are compact and lightweight. This makes them easy to install and suitable for use in systems where space is limited or where weight is a concern.

4.4. Low Maintenance

The design of the Lugged Stainless Steel High-Performance Butterfly Valve is simple and straightforward, with fewer moving parts than many other valve types. This reduces the need for frequent maintenance and minimizes the risk of mechanical failure.

4.5. Leak-Proof Sealing

The high-performance seating system ensures that the valve provides a tight shutoff. This makes it highly reliable for applications where leakage is unacceptable, such as in hazardous fluid systems.

4.6. Flexibility in Installation

The lugged design enables easy installation and removal of the valve without the need for welding or additional pipe fittings. This flexibility is particularly useful in applications where valves need to be frequently replaced or maintained.

The use of stainless steel ensures that these valves can withstand corrosive environments, making them ideal for applications involving aggressive fluids like chemicals, wastewater, or saline water. The stainless steel also ensures longer valve life, reducing the need for frequent replacements.

4.2. High Performance at Elevated Temperatures and Pressures

High-performance butterfly valves are designed to handle extreme conditions, including high-pressure and high-temperature systems. The valve’s design and material choice make it ideal for steam, gas, and other challenging applications that require robust performance.

4.3. Compact and Lightweight

Compared to other types of valves, such as gate or globe valves, butterfly valves are compact and lightweight. This makes them easy to install and suitable for use in systems where space is limited or where weight is a concern.

4.4. Low Maintenance

The design of the Lugged Stainless Steel High-Performance Butterfly Valve is simple and straightforward, with fewer moving parts than many other valve types. This reduces the need for frequent maintenance and minimizes the risk of mechanical failure.

4.5. Leak-Proof Sealing

The high-performance seating system ensures that the valve provides a tight shutoff. This makes it highly reliable for applications where leakage is unacceptable, such as in hazardous fluid systems.

4.6. Flexibility in Installation

The lugged design enables easy installation and removal of the valve without the need for welding or additional pipe fittings. This flexibility is particularly useful in applications where valves need to be frequently replaced or maintained.

5. Applications of Lugged Stainless Steel High-Performance Butterfly Valve

Due to their high performance, reliability, and versatility, Lugged Stainless Steel High-Performance Butterfly Valves are used across a wide range of industries:

5.1. Oil & Gas Industry

In the oil and gas sector, butterfly valves are used in pipelines, pump stations, and processing facilities to control the flow of oil, gas, and other fluids. The corrosion-resistant stainless steel construction is especially important in offshore applications where exposure to saltwater and other harsh environments is common.

5.2. Water and Wastewater Treatment

These valves are frequently used in water and wastewater treatment plants to regulate the flow of water, chemicals, and slurries. Their resistance to corrosion and ability to provide tight shutoff makes them ideal for controlling and isolating flow in harsh water treatment environments.

5.3. Chemical and Petrochemical Industries

In chemical processing and petrochemical facilities, butterfly valves control the flow of chemicals, fuels, and other volatile liquids. Their ability to handle high temperatures and pressures makes them indispensable in these applications.

5.4. Power Generation

In power plants, high-performance butterfly valves regulate the flow of steam, water, and gases through various systems. The stainless steel construction ensures they can withstand high-temperature steam and corrosive conditions over extended periods.

5.5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, butterfly valves regulate the flow of air, water, and other fluids in ducts and pipes. Their compact design and efficient operation make them a preferred choice in HVAC applications.

5.1. Oil & Gas Industry

In the oil and gas sector, butterfly valves are used in pipelines, pump stations, and processing facilities to control the flow of oil, gas, and other fluids. The corrosion-resistant stainless steel construction is especially important in offshore applications where exposure to saltwater and other harsh environments is common.

5.2. Water and Wastewater Treatment

These valves are frequently used in water and wastewater treatment plants to regulate the flow of water, chemicals, and slurries. Their resistance to corrosion and ability to provide tight shutoff makes them ideal for controlling and isolating flow in harsh water treatment environments.

5.3. Chemical and Petrochemical Industries

In chemical processing and petrochemical facilities, butterfly valves control the flow of chemicals, fuels, and other volatile liquids. Their ability to handle high temperatures and pressures makes them indispensable in these applications.

5.4. Power Generation

In power plants, high-performance butterfly valves regulate the flow of steam, water, and gases through various systems. The stainless steel construction ensures they can withstand high-temperature steam and corrosive conditions over extended periods.

5.5. HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, butterfly valves regulate the flow of air, water, and other fluids in ducts and pipes. Their compact design and efficient operation make them a preferred choice in HVAC applications.

6. Maintenance and Troubleshooting

6.1. Inspection and Maintenance

Routine inspection and maintenance of Lugged Stainless Steel High-Performance Butterfly Valves are essential for ensuring optimal performance. Regularly check for:

Wear or damage to the valve disc and seat

Corrosion or scaling of the valve components

Loose bolts or lugs

Proper actuator function

6.2. Troubleshooting Common Issues

Leakage: If the valve leaks, inspect the seat and disc for damage or debris. Clean the valve and ensure the seat is intact.

Sticking or Jammed Disc: Check the shaft and actuator for wear, corrosion, or misalignment. Lubricate as necessary.

Improper Seal: If the valve does not provide a tight shutoff, it may be due to a worn or damaged seat or disc. Replace these components as needed.

Routine inspection and maintenance of Lugged Stainless Steel High-Performance Butterfly Valves are essential for ensuring optimal performance. Regularly check for:

Wear or damage to the valve disc and seat

Corrosion or scaling of the valve components

Loose bolts or lugs

Proper actuator function

6.2. Troubleshooting Common Issues

Leakage: If the valve leaks, inspect the seat and disc for damage or debris. Clean the valve and ensure the seat is intact.

Sticking or Jammed Disc: Check the shaft and actuator for wear, corrosion, or misalignment. Lubricate as necessary.

Improper Seal: If the valve does not provide a tight shutoff, it may be due to a worn or damaged seat or disc. Replace these components as needed.