Lug Type Double Offset Butterfly Valves - Reliable Supplier & Manufacturer in China

For high-quality Lug Type Double Offset Butterfly Valves, sourcing from top Chinese manufacturers can significantly impact your projects. At YONGJIA BOPIN VALVE FACTORY, we excel in producing durable and reliable valves that adhere to various industry standards. Our double offset design not only ensures superior sealing but also minimizes torque, enhancing performance in demanding applications. With advanced manufacturing processes, we guarantee consistent quality to meet your bulk production needs. Each valve undergoes rigorous testing to ensure it delivers peak performance. Clients can expect competitive pricing and responsive customer support tailored to their specific requirements. Our expertise extends to optimizing supply chains and providing necessary certifications. Partner with us to benefit from sourcing directly from reputable manufacturers in China. Elevate your projects with our premium butterfly valves!

7 Key Tips To Lug Type Double Offset Butterfly Valve Service Backed by Expertise For the Current Year

When it comes to the maintenance and service of Lug Type Double Offset Butterfly Valves, understanding the nuances of their operation is vital for global buyers seeking reliability and efficiency in their systems. At BOPIN VALVE, our expertise allows us to offer tailored solutions that meet the specific requirements of our customers. Here are seven key tips to ensure optimal performance for your valves this year. First, regular inspection of seals and disc position is essential. By ensuring these components remain in good condition, you can avoid potential leaks and operational failures. Additionally, consider the unique materials and applications that your valves will encounter. BOPIN VALVE specializes in designing valves made from varying materials that withstand specific pressures and environmental conditions, enhancing their durability. Secondly, pay attention to the installation process. Proper alignment and support are critical to prevent undue stress on the valve body. Our team is adept at providing guidance and custom solutions that fit your specific operational needs, ensuring seamless integration. Furthermore, keep a detailed log of service history to track performance and identify any recurring issues. This proactive approach not only improves efficiency but also builds a foundation for reliable long-term service. By leveraging our expertise and choosing the right valve tailored for your application, you'll achieve greater reliability and operational efficiency.

7 Key Tips To Lug Type Double Offset Butterfly Valve Service Backed by Expertise For the Current Year

| Tip Number | Service Tip | Importance Level | Frequency of Service | Expert Recommendation |

|---|---|---|---|---|

| 1 | Regular Inspection | High | Monthly | Inspect seals and seating surfaces for wear. |

| 2 | Lubrication | Medium | Every 6 months | Use suitable grease to reduce friction. |

| 3 | Testing Functionality | High | Quarterly | Perform operation tests to ensure proper sealing. |

| 4 | Check for Corrosion | High | Biannually | Inspect exterior and interior surfaces for signs of corrosion. |

| 5 | Ensure Proper Alignment | Medium | Annually | Verify that the valve body is correctly aligned in the pipeline. |

| 6 | Replace Worn Parts | High | As needed | Replace any damaged or excessively worn components immediately. |

| 7 | Documentation of Service | Medium | Ongoing | Keep detailed records of all maintenance activities. |

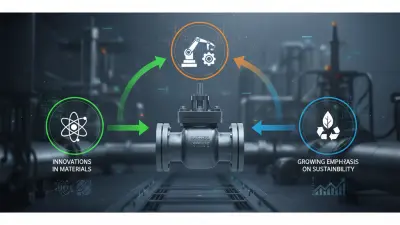

Ultimate Guide To Lug Type Double Offset Butterfly Valve Market Leader Outperforms the Competition

D

Daniel Reed

Absolutely top-notch quality! The follow-up service was excellent, and the team was very knowledgeable.

20 June 2025

O

Oliver Baker

Really impressed with the overall quality. The service team was very professional and attentive.

09 May 2025

L

Liam Perez

I appreciate the quality and great customer service! The staff was delightful to work with.

03 June 2025

L

Logan Edwards

Absolutely love the item! The support team was efficient and very knowledgeable.

06 July 2025

E

Ella Reed

Top-notch quality! The after-sales team provided exceptional service and advice.

10 May 2025

I

Isaac Turner

Exceptional quality! The representatives were very helpful and efficient in their service.

11 June 2025