FLANGED FORGED STEEL Y-STRAINER

A forged steel Y strainer is an essential component in many industrial systems, designed to filter out debris and contaminants from liquids or gases that flow through pipelines. The "Y" shape refers to the physical structure of the strainer, which resembles the letter "Y," and the forged steel construction indicates that the body of the strainer is created through a forging process, ensuring greater strength and durability. In this article, we will explore the various aspects of forged steel Y strainers, including their design, functionality, applications, types, advantages, maintenance, and considerations for selection.

BUT-WELDED END TRIPLE OFFSET BUTTERFLY VALVE

A but-welded end triple offset butterfly valve is a highly specialized valve used in many industrial applications to control the flow of fluids, gases, or steam within a pipeline. This valve combines the characteristics of a butterfly valve with advanced sealing technology to offer exceptional performance, durability, and efficiency in demanding environments. The but-welded end triple offset butterfly valve is an advanced valve design offering a combination of durability, high-performance sealing, low operating torque, and leak-proof operation. Its unique design makes it an excellent choice for demanding industries such as oil and gas, power generation, water treatment, and chemical processing. With its minimal maintenance requirements and long operational life, it provides a cost-effective solution for controlling the flow of fluids or gases in critical systems.

3 WAY FORGED STEEL BALL VALVE

Forged steel F304 3-way ball valves are essential components in fluid and gas control systems, widely used in industrial applications due to their high strength, durability, and resistance to corrosion. These valves are designed for directing, mixing, or diverting flow in a piping system. Manufactured using forged stainless steel F304, they offer superior performance in high-pressure and high-temperature environments

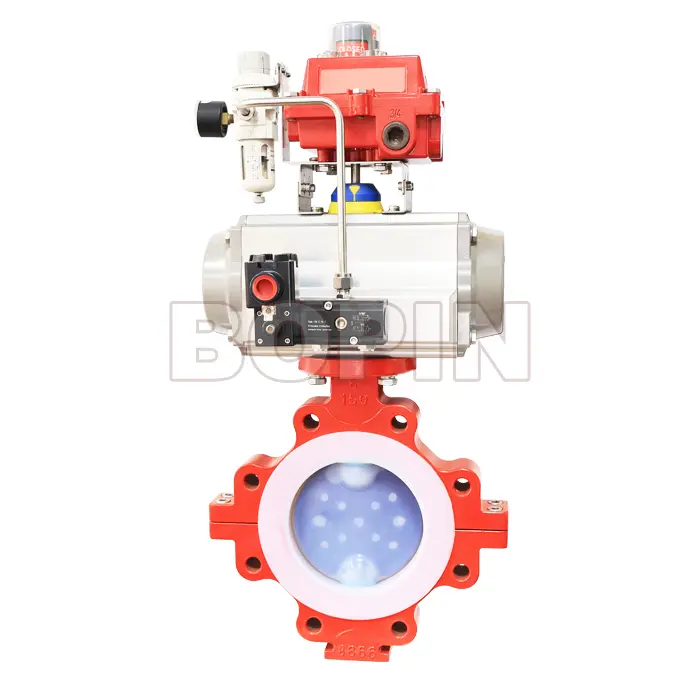

FULLY FLUORINE-LINED VALVES

Fully fluorine-lined valves are specialized industrial valves designed to handle highly corrosive and aggressive chemical applications. These valves incorporate a lining of fluoropolymers, such as polytetrafluoroethylene (PTFE), perfluoroalkoxy (PFA), or fluorinated ethylene propylene (FEP), to provide exceptional chemical resistance, durability, and longevity. They are widely used in industries such as chemical processing, pharmaceuticals, water treatment, and semiconductor manufacturing.

PRESSURE SEALED VALVES

Pressure sealed valves are an essential component in a wide range of industrial systems where the safe and reliable control of fluid or gas flow is paramount. These valves are designed to operate under high-pressure conditions, preventing leaks and ensuring system integrity. In this article, we will explore what pressure sealed valves are, their function, design, applications, and benefits.

Plug Valves Manufacturers

Introduction API 599, published by the American Petroleum Institute (API), is a widely recognized standard for the design, construction, testing, and performance requirements of plug valves, particularly for the oil, gas, and petrochemical industries. This standard ensures the reliability, safety, and operational efficiency of plug valves in various critical applications, such as controlling the flow of fluids and gases under high pressures and temperatures. Plug valves are essential in numerous processes due to their ability to provide a tight seal, simple operation, and effective flow regulation.

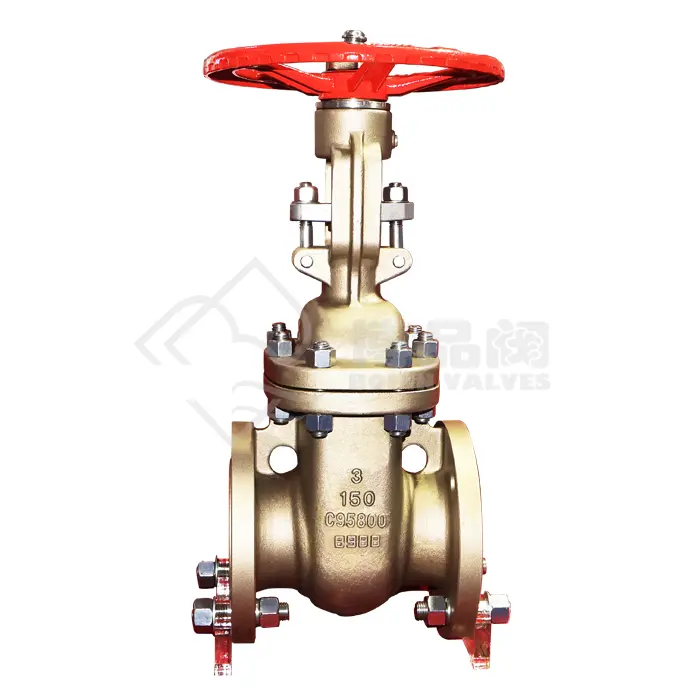

Forged Steel Valves

Forged steel valves are a crucial component in many industrial systems, offering significant advantages in terms of strength, durability, and reliability. The forging process enhances the material properties of the steel, ensuring that these valves can withstand extreme pressures, temperatures, and corrosive environments. With a wide range of applications across industries such as oil and gas, power generation, chemical processing, and water treatment, forged steel valves continue to play an essential role in ensuring the smooth operation of critical systems. By choosing the right type of forged steel valve for each application, industries can benefit from improved performance, reduced maintenance, and longer service life.

Forged Steel Check Valve

A forged steel swing check valve is an essential component in many industrial systems, providing reliable backflow prevention with a simple, effective mechanism. Made from forged steel, these valves offer exceptional durability, high-pressure and high-temperature resistance, and excellent performance across a wide range of applications. Whether used in pipelines, chemical processing, or power generation, the forged steel swing check valve ensures that systems operate safely and efficiently by preventing reverse flow and minimizing the risk of damage or contamination.