0102030405

FULLY FLUORINE-LINED VALVES

Features of Fully Fluorine-Lined Valves

1. Superior Chemical Resistance

Fluorine-lined valves are designed to resist strong acids, bases, and other aggressive chemicals that would typically degrade standard valve materials. PTFE, PFA, and FEP linings offer near-universal chemical resistance, making these valves ideal for highly corrosive applications.

2. High Temperature Tolerance

Fluoropolymers have excellent thermal stability, allowing these valves to function effectively in both high and low temperatures. PTFE-lined valves, for example, can operate in temperatures ranging from -200°C to 260°C, ensuring reliability in extreme conditions.

3. Low Friction and Anti-Adhesive Properties

The smooth surface of fluoropolymers prevents material buildup, reducing the risk of blockages and contamination. This feature is particularly beneficial in processes requiring high-purity materials, such as pharmaceutical and semiconductor industries.

4. Leak Prevention and Tight Sealing

Fully fluorine-lined valves provide excellent sealing performance due to the flexibility and resilience of the fluoropolymer lining. This ensures minimal leakage, even under high-pressure conditions, making them a safe choice for hazardous media.

5. Durability and Longevity

Compared to conventional valves, fluorine-lined valves offer extended service life due to their resistance to corrosion, wear, and chemical degradation. This reduces maintenance costs and downtime, leading to improved operational efficiency.

Types of Fully Fluorine-Lined Valves

1. Ball Valves

Fluorine-lined ball valves offer excellent flow control, minimal pressure drop, and full bore design, making them suitable for high-purity and corrosive applications.

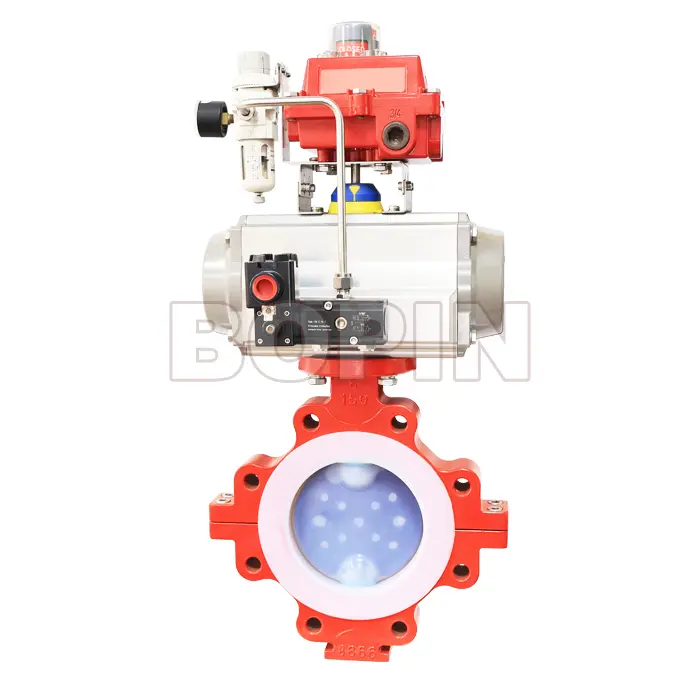

2. Butterfly Valves

These valves feature a compact design with a fluoropolymer-lined disc and body, providing effective shut-off and regulation in corrosive environments.

3. Diaphragm Valves

With a PTFE-lined diaphragm, these valves are ideal for handling aggressive chemicals, ensuring contamination-free operation in pharmaceutical and food industries.

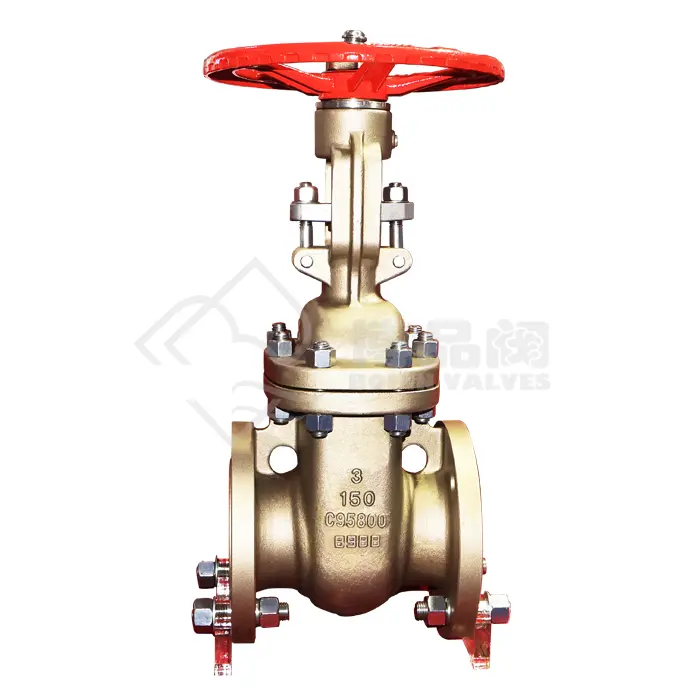

4. Gate Valves

Fluorine-lined gate valves provide robust shut-off capabilities, particularly in applications requiring minimal turbulence and pressure loss.

5. Globe Valves

Offering precise flow control, fluorine-lined globe valves are used in applications demanding fine regulation and high resistance to aggressive fluids.

Applications of Fully Fluorine-Lined Valves

1. Chemical Processing Industry

These valves are widely used for handling acids, alkalis, solvents, and other corrosive chemicals in chemical plants

2. Pharmaceutical and Biotechnology

Their high purity and contamination-resistant properties make them essential for processing active pharmaceutical ingredients (APIs) and other sensitive compounds.

3. Water and Wastewater Treatment

Fluorine-lined valves are used in water treatment plants to handle chlorine, ozone, and other aggressive disinfectants.

4. Food and Beverage Industry

Non-reactive and easy-to-clean surfaces make these valves ideal for handling food-grade chemicals and ensuring hygiene in processing plants.

5. Semiconductor Manufacturing

Used in ultrapure water and chemical handling applications, these valves ensure that semiconductor fabrication processes remain contamination-free.

Fully fluorine-lined valves offer an unparalleled combination of chemical resistance, durability, and reliability. Their ability to withstand harsh environments, resist contamination, and provide excellent sealing makes them indispensable in various industries. Investing in high-quality fluorine-lined valves leads to improved operational efficiency, reduced maintenance costs, and enhanced safety, making them a valuable asset for any facility handling aggressive fluids.