FORGED STAINLESS STEEL BELLOWS GATE VALVE

1. Introduction

2. Design Standards and Compliance

|

Item

|

Standard / Specification

|

|

Design & Manufacture

|

API 602 / ASME B16.34

|

|

Flange End Connection

|

ASME B16.5 (RF, RTJ)

|

|

Face-to-Face Dimension

|

ASME B16.10

|

|

Pressure-Temperature Rating

|

ASME B16.34

|

|

Testing & Inspection

|

API 598

|

|

Materials & Marking

|

ASTM, MSS-SP-25

|

|

Optional Standard

|

BS 5352, ISO 15848 (Emission Standard)

|

|

Pressure Class Range

|

Class 150, 300, 600, 900

|

|

Size Range

|

½” – 4” (DN15 – DN100)

|

|

Operation

|

Manual handwheel, gearbox, or electric actuator

|

3.Construction Features

Main Construction Features:

|

Component

|

Detailed Description

|

|

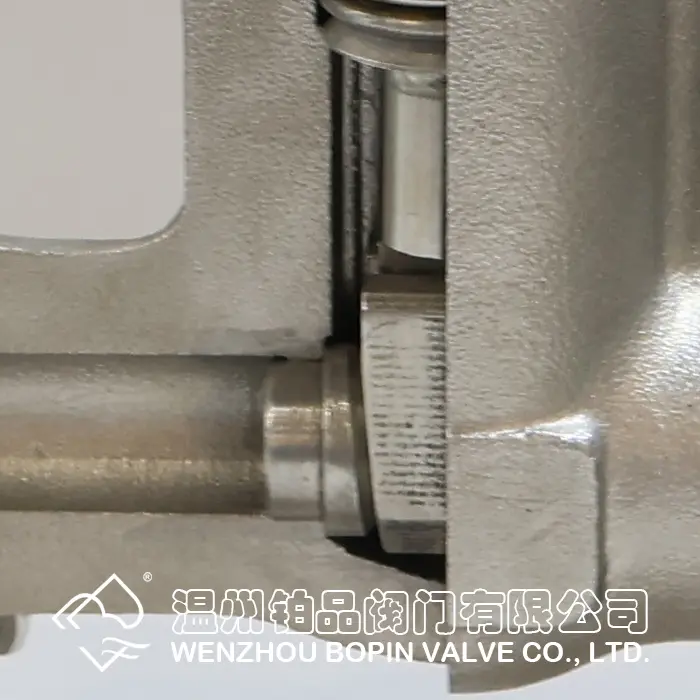

Bellows Seal Assembly

|

A multiple-ply stainless steel bellows (commonly SS304, SS316L, or Inconel 625) is welded to the stem and bonnet, forming a sealed barrier that eliminates external leakage. This structure provides over 10,000 operational cycles without failure, greatly extending valve life.

|

|

Forged Body and Bonnet

|

The valve body and bonnet are precision-forged to ensure superior grain flow and high mechanical strength. Forged construction minimizes porosity and casting defects, resulting in higher pressure capability and better resistance to thermal shock.

|

|

Bolted Bonnet Connection

|

The bolted bonnet allows easy access for maintenance while ensuring secure pressure containment. Spiral wound or graphite gaskets provide leak-free sealing at the body-bonnet interface.

|

|

Backseat Design

|

A precision-machined backseat in the bonnet provides an additional sealing surface when the valve is fully open, protecting the bellows and packing from system pressure and prolonging service life.

|

|

Flexible Wedge

|

The solid or flexible wedge design ensures tight sealing and compensates for minor body seat misalignment caused by temperature fluctuations, reducing the risk of jamming.

|

|

Stem and Yoke Construction

|

The rising stem allows visual indication of valve position. It is precision-machined, ground, and polished for smooth operation and reduced friction between stem and packing.

|

|

Forged Flanged Ends

|

The valve ends are machined according to ASME B16.5 flange dimensions. Raised Face (RF) or Ring Type Joint (RTJ) options are available for high-pressure sealing integrity.

|

4. Materials of Construction

The valve is available in a variety of forged stainless steel grades to suit different media and operating environments.

|

Component

|

Material Options (ASTM / AISI Grade)

|

Remarks

|

|

Body & Bonnet

|

ASTM A182 F304 / F304L / F316 / F316L / F321

|

Corrosion-resistant stainless steels

|

|

Bellows

|

SS304, SS316L, Inconel 625

|

Welded multi-layer bellows assembly

|

|

Disc / Wedge

|

A182 F316 / F316L with hard-faced seating

|

Optional Stellite 6 overlay

|

|

Stem

|

A182 F316 / F321

|

Ground and polished surface

|

|

Seat Ring

|

A276 316L or Stellite

|

Integral or welded type

|

|

Bonnet Gasket

|

Graphite + SS304 spiral wound

|

High-temperature sealing

|

|

Packing

|

Graphite or PTFE

|

Secondary seal

|

|

Handwheel

|

Carbon steel / Ductile iron

|

Ergonomic design for manual operation

|

Optional materials like Duplex (F51), Super Duplex (F53), or Alloy 20 can be supplied for specialized applications such as sour gas or acid service.

5. Working Principle

The bellows sealed gate valve operates through the linear movement of a wedge gate that opens or closes the flow passage. When the handwheel is turned counterclockwise, the stem rises, lifting the gate off the seat to allow fluid flow. Turning the handwheel clockwise lowers the gate back onto the seat, completely stopping the flow.

During operation, the bellows flex axially with the stem movement but maintains a hermetic seal between the stem and bonnet. This prevents any process medium from escaping through the stem area — a common leakage path in conventional gate valves.

An auxiliary gland packing serves as a secondary seal and a safety backup in the unlikely event of bellows rupture, ensuring continued sealing integrity.

6. Key Advantages

Zero Leakage to Atmosphere

The bellows assembly provides absolute sealing between the valve interior and environment, complying with stringent fugitive emission standards such as ISO 15848 and TA-Luft.

Long Service Life

The welded multi-ply bellows design accommodates thousands of open/close cycles without fatigue or deformation.

Enhanced Safety and Environmental Protection

Ideal for toxic, flammable, or hazardous media — preventing accidental emissions and ensuring compliance with safety regulations.

Forged Stainless Steel Construction

Offers excellent corrosion resistance, mechanical strength, and dimensional stability under high temperature and pressure.

Maintenance-Free Operation

The bellows eliminates the need for frequent packing adjustment or replacement, reducing downtime and operational costs.

Compact and Robust Design

The forged body provides smaller dimensions and lighter weight compared to cast valves of similar pressure ratings.

Optional Features

Drain plug for cavity venting

By-pass connection for pressure equalization

Locking device for position security

Actuator mounting pad for automation

7. Typical Applications

The API Forged Stainless Steel Bellows Sealed Gate Valve is suitable for a broad range of industrial applications, especially where leakage prevention and environmental safety are paramount:

Refineries and Petrochemical Plants – Handling hydrocarbons, H₂S, or hot oil lines

Power Generation – Steam isolation and condensate systems

Chemical Processing – Corrosive and toxic fluids

Pharmaceutical Industry – High-purity media control

Cryogenic and Gas Systems – Ensuring tight shutoff under low temperature

Vacuum Systems – Maintaining absolute tightness in low-pressure applications

8. Testing and Inspection

Each valve is subjected to rigorous quality control and inspection procedures as per API 598 standards, including:

Shell Test: Hydrostatic pressure test for body integrity

Seat Leakage Test: Ensures tight sealing capability

Bellows Leak Test: Helium leak test for zero emission verification

Operational Test: Cycle test for smooth operation and stem alignment

Dimensional and Visual Inspection: Per ASME and ASTM standards

All valves are supplied with EN 10204 3.1 Material Test Certificates, hydrostatic test records, and traceability documentation.