0102030405

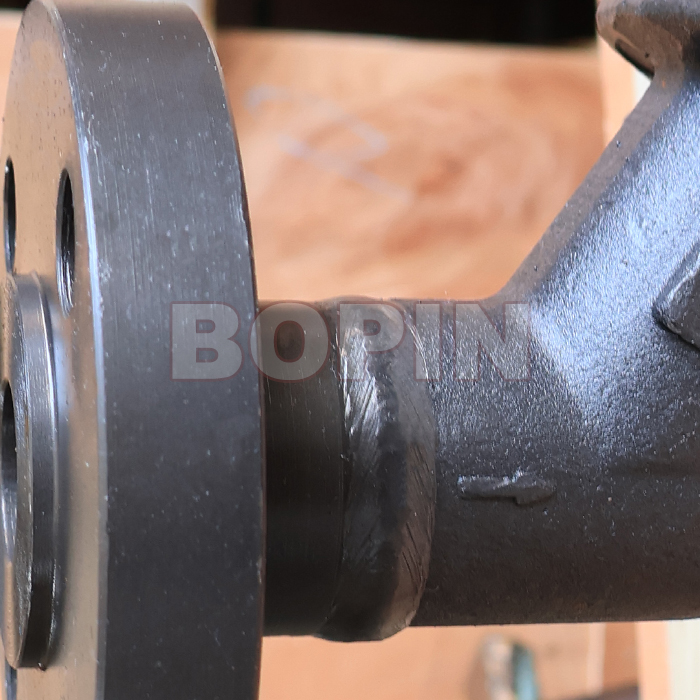

FLANGED FORGED STEEL Y-STRAINER

What is a Forged Steel Y Strainer

A forged steel Y strainer is a type of strainer used to filter particles from a fluid or gas. It is commonly used in pipelines for industrial applications where the flow of liquids or gases can carry debris, particles, or contaminants that could damage machinery or affect system performance. The Y strainer's primary function is to ensure that the fluid or gas passing through a system is free from large particulates.

The strainer is named after its "Y" shape, which is designed to make installation in pipelines convenient, as it allows for better space utilization, ease of maintenance, and higher flow efficiency. Forged steel refers to the manufacturing process used to create the body of the strainer. Unlike cast steel, which is poured into molds, forged steel is formed by applying heat and pressure to a solid billet of steel, resulting in a stronger, more durable product.

The strainer is named after its "Y" shape, which is designed to make installation in pipelines convenient, as it allows for better space utilization, ease of maintenance, and higher flow efficiency. Forged steel refers to the manufacturing process used to create the body of the strainer. Unlike cast steel, which is poured into molds, forged steel is formed by applying heat and pressure to a solid billet of steel, resulting in a stronger, more durable product.

Forged Steel Y Strainer Design and Construction

The construction of a forged steel Y strainer includes several critical components:

Body: The main structure of the strainer, which is forged from a steel billet to provide excellent mechanical strength. The body is typically designed to be resistant to corrosion and wear.

Filter Element: The filter or straining element inside the body of the Y strainer is usually made of stainless steel mesh or perforated metal. This filter traps debris and other particulate matter from the fluid or gas flow. The size of the mesh can vary depending on the filtration requirements.

Inlet and Outlet Ports: The inlet and outlet ports are the openings through which the fluid enters and exits the strainer. These are typically flanged or threaded to facilitate easy connection to the pipeline.

Cap or Lid: The cap or lid of the Y strainer is used to cover the filter element and is usually removable for cleaning and maintenance. The cap is typically sealed with a gasket to prevent leakage.

Blow-off Valve: Many forged steel Y strainers come with a blow-off valve that allows operators to flush out accumulated debris without removing the filter element.

The design of the Y strainer allows for a compact and robust structure that is easy to install and maintain, making it a reliable choice in demanding environments.

Body: The main structure of the strainer, which is forged from a steel billet to provide excellent mechanical strength. The body is typically designed to be resistant to corrosion and wear.

Filter Element: The filter or straining element inside the body of the Y strainer is usually made of stainless steel mesh or perforated metal. This filter traps debris and other particulate matter from the fluid or gas flow. The size of the mesh can vary depending on the filtration requirements.

Inlet and Outlet Ports: The inlet and outlet ports are the openings through which the fluid enters and exits the strainer. These are typically flanged or threaded to facilitate easy connection to the pipeline.

Cap or Lid: The cap or lid of the Y strainer is used to cover the filter element and is usually removable for cleaning and maintenance. The cap is typically sealed with a gasket to prevent leakage.

Blow-off Valve: Many forged steel Y strainers come with a blow-off valve that allows operators to flush out accumulated debris without removing the filter element.

The design of the Y strainer allows for a compact and robust structure that is easy to install and maintain, making it a reliable choice in demanding environments.

Forging Process in Steel Strainer Construction

The term "forged steel" refers to the specific manufacturing process that involves shaping the steel using compressive forces, often at high temperatures. This process improves the internal grain structure of the steel, resulting in enhanced strength and durability compared to cast or machined steel.

In the forging process, a steel billet (a solid block of steel) is heated to a high temperature and then pressed into a mold or die under high pressure. This process increases the material’s density, reduces internal defects, and improves mechanical properties such as tensile strength, impact resistance, and fatigue resistance. Forged steel Y strainers are particularly valuable in high-pressure or high-temperature applications because they can withstand extreme operational conditions.

In the forging process, a steel billet (a solid block of steel) is heated to a high temperature and then pressed into a mold or die under high pressure. This process increases the material’s density, reduces internal defects, and improves mechanical properties such as tensile strength, impact resistance, and fatigue resistance. Forged steel Y strainers are particularly valuable in high-pressure or high-temperature applications because they can withstand extreme operational conditions.

Applications of Forged Steel Y Strainers

Forged steel Y strainers are versatile and widely used in various industries, including:

Oil and Gas: In the oil and gas industry, forged steel Y strainers are employed to filter debris from the fluid lines, preventing damage to pumps, valves, and compressors. They are especially useful in offshore platforms, refineries, and pipelines where the fluid flow may contain impurities.

Chemical and Petrochemical: These strainers are used in chemical plants and petrochemical facilities to filter out solid particles from reactive chemicals or hazardous fluids. Their ability to handle high temperatures and pressures makes them ideal for these challenging environments.

Water Treatment: Forged steel Y strainers are commonly found in water filtration systems, helping to prevent dirt and particulate matter from entering the system, ensuring the water remains clean and safe for use.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, these strainers help ensure that circulating water or other fluids remain free of contaminants that could harm the system.

Food and Beverage Industry: In food processing plants, these strainers help maintain the quality and safety of liquids by removing foreign particles that might otherwise contaminate the products.

Oil and Gas: In the oil and gas industry, forged steel Y strainers are employed to filter debris from the fluid lines, preventing damage to pumps, valves, and compressors. They are especially useful in offshore platforms, refineries, and pipelines where the fluid flow may contain impurities.

Chemical and Petrochemical: These strainers are used in chemical plants and petrochemical facilities to filter out solid particles from reactive chemicals or hazardous fluids. Their ability to handle high temperatures and pressures makes them ideal for these challenging environments.

Water Treatment: Forged steel Y strainers are commonly found in water filtration systems, helping to prevent dirt and particulate matter from entering the system, ensuring the water remains clean and safe for use.

HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, these strainers help ensure that circulating water or other fluids remain free of contaminants that could harm the system.

Food and Beverage Industry: In food processing plants, these strainers help maintain the quality and safety of liquids by removing foreign particles that might otherwise contaminate the products.

Types of Forged Steel Y Strainers

Forged steel Y strainers come in different variants, designed for various applications and operating conditions. The main types include:

Simplex Y Strainer: A single strainer with one filter element, used for less critical applications where continuous operation is not as important. Simplex strainers require manual cleaning or replacement of the filter.

Duplex Y Strainer: This variant consists of two Y strainers in parallel, allowing for continuous filtration. While one filter is in use, the other can be cleaned or replaced without interrupting the fluid flow.

Multi-element Y Strainer: These strainers contain multiple filter elements for handling higher flow rates or when finer filtration is required. They are suitable for systems with large volumes of fluid or gas.

Simplex Y Strainer: A single strainer with one filter element, used for less critical applications where continuous operation is not as important. Simplex strainers require manual cleaning or replacement of the filter.

Duplex Y Strainer: This variant consists of two Y strainers in parallel, allowing for continuous filtration. While one filter is in use, the other can be cleaned or replaced without interrupting the fluid flow.

Multi-element Y Strainer: These strainers contain multiple filter elements for handling higher flow rates or when finer filtration is required. They are suitable for systems with large volumes of fluid or gas.

Advantages of Forged Steel Y Strainers

High Strength and Durability: Forged steel Y strainers offer superior strength compared to cast or machined versions, making them ideal for high-pressure and high-temperature applications.

Corrosion Resistance: Steel alloys used in forging are highly resistant to corrosion, ensuring that the strainer maintains its integrity over time, even in harsh environments.

Reduced Maintenance Needs: The durability of forged steel means that Y strainers require less frequent maintenance and have a longer operational life.

Cost Efficiency: Though forged steel Y strainers may have a higher upfront cost, their longevity and reliability lead to lower maintenance costs and reduced downtime over time.

Versatility: They are available in a variety of configurations and sizes, making them suitable for a wide range of industrial applications.

Corrosion Resistance: Steel alloys used in forging are highly resistant to corrosion, ensuring that the strainer maintains its integrity over time, even in harsh environments.

Reduced Maintenance Needs: The durability of forged steel means that Y strainers require less frequent maintenance and have a longer operational life.

Cost Efficiency: Though forged steel Y strainers may have a higher upfront cost, their longevity and reliability lead to lower maintenance costs and reduced downtime over time.

Versatility: They are available in a variety of configurations and sizes, making them suitable for a wide range of industrial applications.

Maintenance of Forged Steel Y Strainers

Regular maintenance is crucial to ensure that forged steel Y strainers continue to perform efficiently. Maintenance tasks include:

Cleaning: Periodically cleaning the filter element to remove accumulated debris is essential for maintaining optimal flow rates.

Inspection: Regular inspections help identify wear and tear, corrosion, or any other damage to the strainer components. This ensures that problems are addressed before they lead to system failures.

Repacking and Gasket Replacement: The cap or lid of the Y strainer should be checked for leaks and repacked or resealed as necessary.

Blow-off Cleaning: Some models come with a blow-off valve that allows operators to flush out contaminants without removing the filter.

Cleaning: Periodically cleaning the filter element to remove accumulated debris is essential for maintaining optimal flow rates.

Inspection: Regular inspections help identify wear and tear, corrosion, or any other damage to the strainer components. This ensures that problems are addressed before they lead to system failures.

Repacking and Gasket Replacement: The cap or lid of the Y strainer should be checked for leaks and repacked or resealed as necessary.

Blow-off Cleaning: Some models come with a blow-off valve that allows operators to flush out contaminants without removing the filter.

Factors to Consider When Selecting a Forged Steel Y Strainer

When selecting a forged steel Y strainer for a particular application, consider the following factors:

Fluid Type: The properties of the fluid (e.g., temperature, viscosity, chemical composition) should be considered to ensure the strainer material is compatible.

Filtration Requirements: The size of the particles to be filtered determines the mesh size and type of filter element to use.

Flow Rate: The required flow rate and pressure specifications of the system will influence the size and design of the Y strainer.

Pressure and Temperature: The maximum operating pressure and temperature should align with the capabilities of the forged steel strainer.

Maintenance Access: Consider how easy it will be to clean or replace the filter element during regular maintenance.

Fluid Type: The properties of the fluid (e.g., temperature, viscosity, chemical composition) should be considered to ensure the strainer material is compatible.

Filtration Requirements: The size of the particles to be filtered determines the mesh size and type of filter element to use.

Flow Rate: The required flow rate and pressure specifications of the system will influence the size and design of the Y strainer.

Pressure and Temperature: The maximum operating pressure and temperature should align with the capabilities of the forged steel strainer.

Maintenance Access: Consider how easy it will be to clean or replace the filter element during regular maintenance.