0102030405

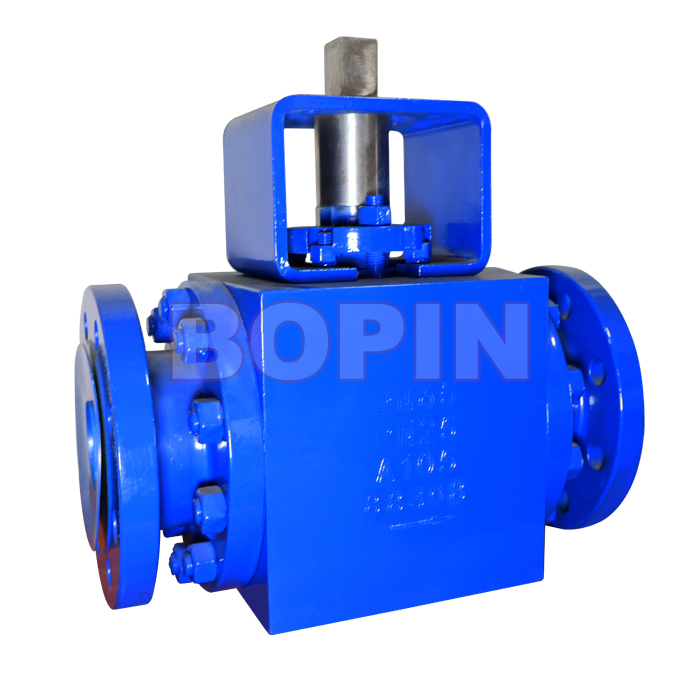

EN Standard Free Forged Steel Three-Way Ball Valve

Understanding the EN Standard

The EN Standard refers to the European Standards, which provide a unified set of rules and guidelines for manufacturing and testing various industrial products. In the case of the EN Standard Free Forged Steel Three-Way Ball Valve, it means that the valve has been manufactured to meet stringent European safety, quality, and operational standards.

EN standards ensure the valve’s compatibility with European Union (EU) regulations, particularly in terms of environmental safety, performance, and material selection. The EN standard establishes specific criteria for design, materials, testing methods, and manufacturing processes, ensuring that the valve offers reliable performance and long service life.

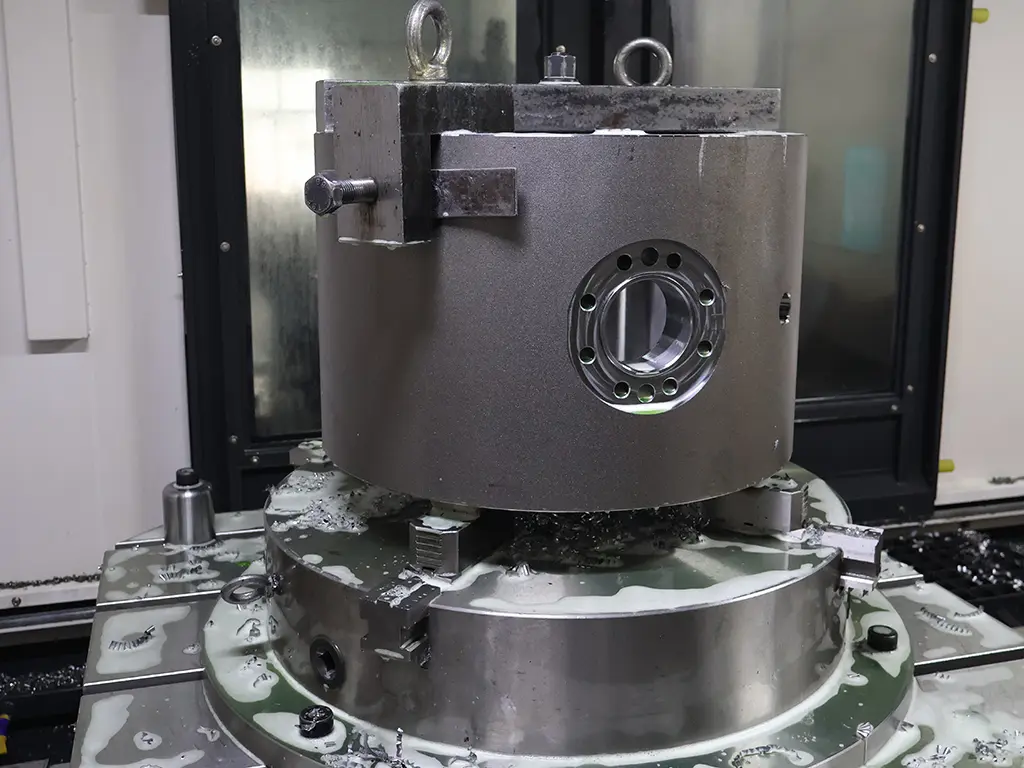

Free Forged Steel: The Backbone of Durability

Forged steel is a popular material used in the manufacturing of high-performance valves. The forging process involves shaping steel under high pressure, resulting in a material with superior mechanical properties compared to cast steel or other alternatives. The free forging process, in particular, allows for greater precision and flexibility, producing valves with exceptional strength, toughness, and resistance to extreme conditions such as high pressure, temperature, and corrosion.

For the EN Standard Free Forged Steel Three-Way Ball Valve, the use of free forged steel ensures that the valve can withstand high operating pressures and temperatures. It also enhances the overall integrity of the valve, preventing issues such as cracking or fatigue under stress. The strength of the material combined with the precision of the forging process leads to a valve that can operate reliably over long periods without failure.

Features of the Three-Way Ball Valve

The three-way ball valve, as the name suggests, has a ball with three ports that allow the valve to control the flow of fluids in multiple directions. Here are some key features:

Ball Design: The ball inside a three-way ball valve has three ports and is typically operated by a handle or actuator to rotate it to different positions. This enables the valve to control flow in various directions—either directing flow from one inlet to two outlets, or mixing flows from two inlets into one outlet.

Port Configurations: There are two common types of port configurations for three-way ball valves:

L-port: This configuration allows the flow to be directed from one inlet to two outlets or vice versa, forming an “L” shape inside the valve.

T-port: The T-port configuration allows flow to be directed from one inlet to two outlets, creating a “T” shape, which allows for more flexibility in flow direction control.

Sealing Performance: Free forged steel three-way ball valves are equipped with tight seals, typically made of materials like PTFE (Polytetrafluoroethylene) or metal, which provide excellent sealing performance. These seals ensure that there is minimal leakage and prevent fluid loss, which is critical in high-pressure or hazardous applications.

Compact Design: Despite their high functionality, three-way ball valves have a compact design. This allows them to fit into spaces where larger valve types may not be suitable, making them ideal for installations where space is limited.

Ease of Operation: The design of the valve makes it simple to operate, either manually with a handle or via an actuator for automated systems. The three-way ball valve provides smooth flow regulation, even with viscous fluids or high-pressure conditions.

Benefits of EN Standard Free Forged Steel Three-Way Ball Valves

The EN Standard Free Forged Steel Three-Way Ball Valve offers several benefits that make it a preferred choice for many industrial applications. These include:

High Strength and Durability: The free forged steel construction gives the valve high tensile strength, resistance to mechanical stresses, and the ability to endure high temperatures and pressures. This makes it ideal for critical and demanding applications.

Versatility in Flow Control: The ability to change the flow direction in a three-way ball valve allows operators to control fluid distribution, mixing, or diversion. This flexibility makes it an essential component in complex piping systems.

Corrosion Resistance: Forged steel, especially when coated with corrosion-resistant materials or treated with protective finishes, can withstand corrosive fluids and harsh environments. This is crucial for industries dealing with aggressive chemicals, seawater, or high-temperature fluids.

Low Maintenance: The precision of the forging process and the high-quality material result in valves that require less maintenance compared to other types. The absence of casting defects also reduces the chances of wear and tear, leading to longer operational life.

Safety and Reliability: EN standards are designed to meet rigorous safety requirements, ensuring that the valve performs consistently under various operational conditions. The high reliability of these valves reduces the risk of failure, which can be costly and dangerous in critical systems.

Applications of EN Standard Free Forged Steel Three-Way Ball Valves

The EN Standard Free Forged Steel Three-Way Ball Valve is widely used across various industries due to its versatility and durability. Here are some typical applications:

Oil and Gas Industry: In the oil and gas sector, these valves are essential for controlling the flow of hydrocarbons through pipelines and storage tanks. The ability to direct and mix flows efficiently is crucial in exploration, drilling, and refinery operations.

Chemical Processing: The valve’s ability to handle aggressive chemicals, along with its leak-proof design, makes it ideal for use in chemical processing plants. It is used for mixing, diverting, or controlling the flow of chemical substances in production lines.

Power Generation: In power plants, these valves are employed to regulate the flow of steam, water, or other fluids used in the generation of power. Their reliability ensures efficient operation in critical systems like boilers, turbines, and condensers.

Water Treatment: The valve’s durability and precise flow control make it valuable in water and wastewater treatment facilities. It helps in managing the flow of water through filtration, chemical dosing, and disinfection systems.

Efficient Operation: Automatic opening and closing reduce the need for manual intervention, improving system safety.

HVAC Systems: In heating, ventilation, and air conditioning systems, three-way ball valves control the distribution of hot or cold fluids to maintain desired temperature conditions in various zones.

Pharmaceutical and Food Processing: These industries require stringent control of flow paths, particularly when dealing with sensitive or hazardous materials. The three-way ball valve ensures safe handling and efficient fluid flow control.

Compliance with International Standards

The EN Standard Free Forged Steel Three-Way Ball Valve adheres to a number of international standards, ensuring its reliability and compatibility with global industrial systems. Common standards include:

ISO 9001: A certification for quality management systems that ensures the valve manufacturer follows standardized processes for consistent quality.

PED (Pressure Equipment Directive): This certification ensures that the valve is designed and manufactured to handle high-pressure environments safely.

API (American Petroleum Institute) Standards: Widely followed in the oil and gas industry, API standards ensure that the valve meets rigorous operational and safety requirements.

ASME (American Society of Mechanical Engineers): ASME standards ensure the valve is capable of withstanding the required temperature and pressure specifications in power and chemical applications.

Marine and Shipbuilding: Installed in seawater, fuel, and ballast systems.

Conclusion

The EN Standard Free Forged Steel Three-Way Ball Valve represents a sophisticated and reliable solution for flow control in industrial applications. Thanks to its robust construction, versatility, and compliance with international standards, it is an essential component in systems that demand high performance and safety. Its ability to operate efficiently in high-pressure, high-temperature, and corrosive environments makes it indispensable in industries ranging from oil and gas to water treatment and chemical processing.

By understanding the valve’s design, materials, benefits, and applications, companies can make informed decisions to optimize their fluid and gas management systems, ensuring greater reliability and efficiency in their operations.