0102030405

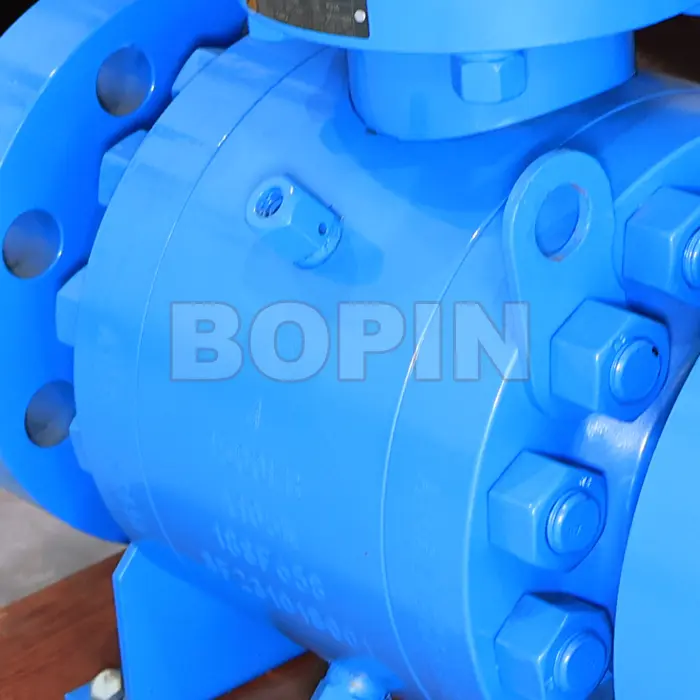

ELECTRICAL FORGED STEEL TRUNNION BALL VALVE

About API 6D

The term "API 6D" refers to a specific standard set by the American Petroleum Institute (API) that governs the design, manufacturing, and testing of valves used in the transportation of oil and gas through pipelines. API 6D covers a wide range of valve types, but the focus here is on the Trunnion Mounted Ball Valve.

API 6D valves are typically found in critical applications, ensuring compliance with international standards for pipeline valves. These valves are designed to handle severe conditions, such as high pressures, extreme temperatures, and highly corrosive environments, while also maintaining tight shutoff capabilities.

What Is Trunnion Mounted Ball Valve

A Trunnion Mounted Ball Valve is a type of ball valve where the ball is supported by trunnions (i.e., pins or shafts) at both the top and bottom of the valve body. This design differs from a floating ball valve, where the ball is held in place only by the pressure of the fluid.

The trunnion-mounted design offers several advantages, including:

Low Torque Requirements: The trunnions reduce the ball's movement, leading to lower operational torque, which makes it easier to operate, especially in larger sizes.

Higher Reliability and Durability: Because the ball is supported by the trunnions, the valve can handle higher pressure differentials without causing excessive wear on the internal components.

Enhanced Flow Capacity: Trunnion-mounted ball valves typically have a larger flow area than floating ball valves, which contributes to reduced flow resistance and minimal pressure drop.

Forged Steel Construction

Forged steel refers to the manufacturing process used for the valve body and other critical components. In this process, steel is heated to a high temperature and then shaped using high-pressure molds. The benefits of using forged steel include:

Forged steel refers to the manufacturing process used for the valve body and other critical components. In this process, steel is heated to a high temperature and then shaped using high-pressure molds. The benefits of using forged steel include:

Strength and Durability: Forged steel is much stronger than cast steel, making it more resistant to cracking and fatigue. This is especially important for valves used in high-pressure environments.

Resistance to Corrosion: Forged steel provides excellent resistance to environmental corrosion, which is vital for valves in the oil, gas, and chemical industries.

Improved Performance: Due to the superior grain structure of forged steel, the valve can perform better in extreme temperatures and pressures, offering longer service life and fewer maintenance needs.

Electrical Actuation

Electrical actuation refers to the use of electric motors and control systems to automate the opening and closing of the valve. This is an important feature for many industrial applications, as it allows for remote operation and real-time control of fluid flow, often integrated with a broader control system for monitoring and automation.

Precision Control: With electrical actuation, operators can control the valve from a distance, reducing the need for personnel to be physically present in hazardous or difficult-to-access locations.

Remote Operation: With electrical actuation, operators can control the valve from a distance, reducing the need for personnel to be physically present in hazardous or difficult-to-access locations.

Integration with SCADA Systems: Electrical actuators are often integrated into Supervisory Control and Data Acquisition (SCADA) systems, allowing operators to monitor and control the valve remotely and efficiently. This integration also supports predictive maintenance by providing real-time data on the valve's condition.

Key Features of the Electrical API 6D Forged Steel Trunnion Mounted Ball Valve

Durable Design: The combination of forged steel construction and trunnion-mounted ball design ensures a long service life, even in high-pressure, high-temperature environments.

Low Torque Operation: The trunnion supports reduce the friction between the ball and valve body, resulting in lower operational torque and easier handling, especially in larger valve sizes.

Leakage Control: The valve provides tight shutoff and leakproof operation, even under high pressure, reducing the risk of fluid leaks in critical pipelines.

Safety Features: These valves are often equipped with fire-safe designs, ensuring that they continue to function even in the event of a fire. Additionally, they may feature emergency sealant injection systems to provide added protection against leaks in case of damage to seals.

Flexible Configuration: The valves can be configured with manual or electric actuators, and they can be equipped with various sealing materials to handle different fluids, including aggressive chemicals and high-temperature gases.

Applications

The Electrical API 6D Forged Steel Trunnion Mounted Ball Valve is designed for use in a variety of demanding industrial applications, including:

Oil and Gas Pipelines: Used in both upstream (production) and downstream (refining and distribution) operations, these valves are critical for controlling the flow of crude oil, natural gas, and refined products.

Petrochemical and Chemical Plants: The ability to handle high-pressure, corrosive, and hazardous chemicals makes these valves ideal for use in chemical processing and petrochemical facilities.

Water Treatment Plants: In water and wastewater treatment systems, these valves are used to regulate the flow of water, ensuring that the system operates efficiently and safely.

Power Generation: Electrical actuated valves are used in power plants, including those using steam, gas, and renewable energy sources, to control fluid flow and pressure within the plant systems.

Mining: In mining operations, particularly in remote locations, the ability to control fluid flows with remote actuation is essential for maintaining operations in harsh environments.

Technical Specifications

The technical specifications for an Electrical API 6D Forged Steel Trunnion Mounted Ball Valve vary depending on the application and valve manufacturer, but some common parameters include:

The technical specifications for an Electrical API 6D Forged Steel Trunnion Mounted Ball Valve vary depending on the application and valve manufacturer, but some common parameters include:

Pressure Rating: These valves are typically rated for pressure classes such as 600, 900, 1500, and 2500 pounds per square inch (PSI), which corresponds to the maximum operating pressure the valve can withstand.

Temperature Range: These valves can operate in extreme temperature ranges, typically from -196°C to 538°C (-320°F to 1000°F), depending on the material and sealing configuration.

Valve Sizes: The valve sizes can range from 2 inches to 48 inches, with larger sizes available for special orders.

Sealing Material: The sealing materials vary based on the application, with options such as PTFE (polytetrafluoroethylene), PCTFE (polychlorotrifluoroethylene), and metal seals for high-temperature or aggressive chemical environments.

Actuation Type: Electrical actuators are commonly used, with options for either on/off control or modulating control, depending on the application.