0102030405

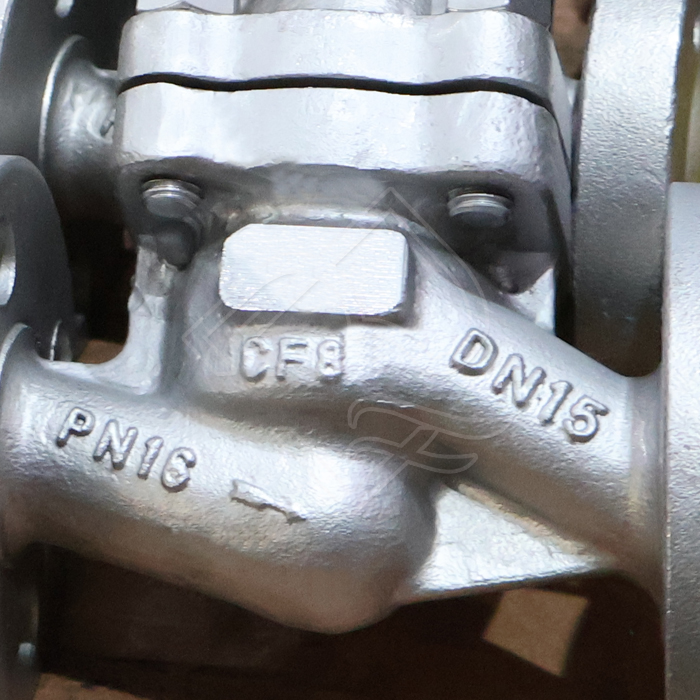

DIN Stainless Steel EN 1.4308 ASTM A351 CF8 Bellows Sealed Globe Valve

Design Standard and Pressure Rating

This globe valve is designed to DIN standards such as DIN 3356 for globe valve design and DIN EN 1092-1 for flanged end dimensions. The PN16 pressure rating indicates a maximum allowable working pressure of 16 bar at ambient temperature, with pressure-temperature limits defined by applicable DIN and EN material standards. The standardized design ensures dimensional compatibility, interchangeability, and reliable performance in European and international piping systems.

Body and Bonnet Construction

The valve body and bonnet are manufactured from ASTM A351 CF8 stainless steel, which is equivalent to EN 1.4308 (GX5CrNi19-10). CF8 stainless steel offers excellent corrosion resistance, good mechanical strength, and suitability for a wide temperature range. This material is particularly effective in handling water, steam, oils, mild chemicals, and weakly corrosive fluids.

The bonnet is typically of bolted design, providing robust pressure containment and easy access for maintenance. A precision-machined sealing surface between the body and bonnet, combined with a high-quality gasket, ensures tight sealing and structural integrity throughout the valve’s service life.

The bonnet is typically of bolted design, providing robust pressure containment and easy access for maintenance. A precision-machined sealing surface between the body and bonnet, combined with a high-quality gasket, ensures tight sealing and structural integrity throughout the valve’s service life.

Bellows Sealed Design

The defining feature of this valve is its bellows seal assembly. The metallic bellows is welded to the stem and bonnet, forming a hermetic seal that completely isolates the process fluid from the atmosphere. This design eliminates leakage through the stem packing area, which is a common failure point in conventional globe valves.

The bellows is usually manufactured from stainless steel with multi-ply or formed construction, allowing it to withstand repeated cycles of opening and closing without fatigue failure. For added safety, the valve is often equipped with a backup gland packing. In the unlikely event of bellows failure, the secondary packing prevents external leakage, ensuring continued safe operation.

The bellows is usually manufactured from stainless steel with multi-ply or formed construction, allowing it to withstand repeated cycles of opening and closing without fatigue failure. For added safety, the valve is often equipped with a backup gland packing. In the unlikely event of bellows failure, the secondary packing prevents external leakage, ensuring continued safe operation.

Stem, Disc, and Seat Design

The valve operates on a linear motion principle, where the stem moves vertically to raise or lower the disc onto the seat. This configuration provides excellent throttling capability and precise control of flow. The stem is typically made from stainless steel with a fine surface finish to ensure smooth operation and long service life.

The disc and seat are designed for tight shutoff and durability. Standard construction features metal-to-metal seating, suitable for high temperature and demanding industrial services. For enhanced wear resistance and sealing performance, seating surfaces may be hard-faced or overlaid with compatible alloys. The globe valve geometry allows uniform seating force distribution, contributing to reliable shutoff and reduced wear.

The disc and seat are designed for tight shutoff and durability. Standard construction features metal-to-metal seating, suitable for high temperature and demanding industrial services. For enhanced wear resistance and sealing performance, seating surfaces may be hard-faced or overlaid with compatible alloys. The globe valve geometry allows uniform seating force distribution, contributing to reliable shutoff and reduced wear.

End Connections

The DIN CF8 bellows sealed globe valve is supplied with flanged ends in accordance with DIN EN 1092-1, PN16. Flanged connections provide secure, leak-free installation and ease of removal for inspection or maintenance. The valve face-to-face dimensions generally comply with DIN EN 558, ensuring compatibility with existing pipeline layouts.

Operational Characteristics

This globe valve is typically handwheel operated, offering smooth and controlled operation. The rising stem design provides a clear visual indication of valve position, which is beneficial for operational safety and maintenance planning. Due to its globe pattern, the valve introduces a higher pressure drop compared to gate valves, but this is offset by its superior flow control and sealing capability.

The bellows sealed construction makes this valve especially suitable for applications involving toxic, flammable, or expensive media, where even minor leakage cannot be tolerated. It is also well suited for steam and thermal oil systems, where high temperatures can rapidly degrade conventional packing materials.

The bellows sealed construction makes this valve especially suitable for applications involving toxic, flammable, or expensive media, where even minor leakage cannot be tolerated. It is also well suited for steam and thermal oil systems, where high temperatures can rapidly degrade conventional packing materials.

Testing and Quality Assurance

Each DIN stainless steel CF8 bellows sealed globe valve PN16 undergoes stringent inspection and testing prior to delivery. Standard tests include shell pressure testing to verify body integrity and seat leakage testing to confirm shutoff performance. Bellows assemblies are often subjected to additional cycle and leak tests to ensure long-term reliability.

Material test certificates, pressure test reports, and dimensional inspection records are typically available, providing full traceability and compliance with project specifications.

Material test certificates, pressure test reports, and dimensional inspection records are typically available, providing full traceability and compliance with project specifications.

Applications and Advantages

Typical applications include chemical processing lines, steam and condensate systems, heat transfer units, pharmaceutical plants, and food processing facilities. The key advantages of this valve include zero stem leakage, excellent corrosion resistance, precise flow control, and reduced maintenance requirements.