0102030405

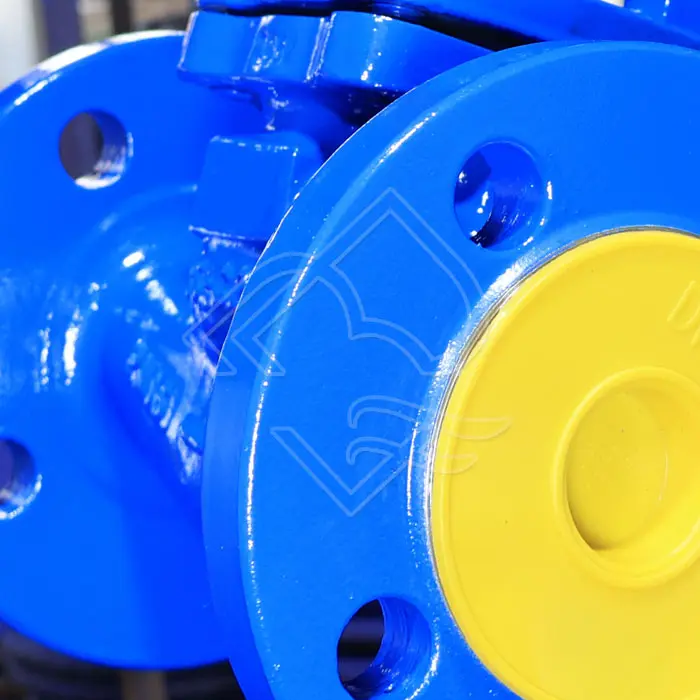

DIN SNDR SPRING LOADED STRAIGHT TYPE GLOBE CHECK VALVE

1. Introduction to the SDNR Globe Check Valve

A Globe Check Valve is a type of check valve that allows fluid to flow in only one direction, typically designed with a globe-shaped body. The SDNR (Spring Loaded, Directly-Normal Return) model utilizes a spring mechanism to assist in the valve’s operation, providing quick and efficient response to changes in pressure. The valve features a "straight-type" design, meaning that the flow path runs in a direct line from the inlet to the outlet, improving efficiency.

When paired with DIN (Deutsches Institut für Normung) specifications, these valves are designed to meet stringent international standards, ensuring high reliability and quality. The term cast steel indicates that the valve body is made of cast steel, offering excellent strength and resistance to high pressures and temperatures.

2. Design and Structure

Valve Body

The body of the DIN Cast Steel SDNR Globe Check Valve is typically made from high-quality cast steel, which is known for its durability, strength, and resistance to corrosion. This material is ideal for handling high-pressure and high-temperature applications, making the valve suitable for industries such as oil and gas, power generation, and chemical processing.

The "straight-type" design of the valve body means that the inlet and outlet ports are aligned directly, offering minimal resistance to fluid flow. This feature ensures a smooth flow path and reduces pressure loss across the valve, enhancing system efficiency.

The body of the DIN Cast Steel SDNR Globe Check Valve is typically made from high-quality cast steel, which is known for its durability, strength, and resistance to corrosion. This material is ideal for handling high-pressure and high-temperature applications, making the valve suitable for industries such as oil and gas, power generation, and chemical processing.

The "straight-type" design of the valve body means that the inlet and outlet ports are aligned directly, offering minimal resistance to fluid flow. This feature ensures a smooth flow path and reduces pressure loss across the valve, enhancing system efficiency.

Spring Mechanism

The spring-loaded feature of the SDNR Globe Check Valve refers to the internal spring that helps in sealing the valve when the flow of fluid stops. The spring provides a counteracting force to the pressure from the flowing fluid, ensuring that the valve closes tightly to prevent backflow. This spring-loaded mechanism improves the valve's responsiveness, allowing it to operate efficiently even in fluctuating pressure conditions.

The spring also helps the valve return to its default closed position when the fluid flow decreases or stops. This feature is especially useful in applications where the system experiences intermittent flow or frequent pressure changes.

The spring-loaded feature of the SDNR Globe Check Valve refers to the internal spring that helps in sealing the valve when the flow of fluid stops. The spring provides a counteracting force to the pressure from the flowing fluid, ensuring that the valve closes tightly to prevent backflow. This spring-loaded mechanism improves the valve's responsiveness, allowing it to operate efficiently even in fluctuating pressure conditions.

The spring also helps the valve return to its default closed position when the fluid flow decreases or stops. This feature is especially useful in applications where the system experiences intermittent flow or frequent pressure changes.

Disc and Seat

The valve disc in a globe check valve is typically made from materials such as stainless steel, which is resistant to wear and corrosion. The disc is designed to seal tightly against the valve seat, ensuring that no fluid can flow in the reverse direction when the valve is closed. In the SDNR design, the spring assists in maintaining the seal, even when the flow of fluid is weak or inconsistent.

The seat of the valve is precision-machined to ensure that the disc can create a perfect seal, preventing any leakage when the valve is closed. This seal is crucial for maintaining system integrity and preventing damage to equipment downstream.

The valve disc in a globe check valve is typically made from materials such as stainless steel, which is resistant to wear and corrosion. The disc is designed to seal tightly against the valve seat, ensuring that no fluid can flow in the reverse direction when the valve is closed. In the SDNR design, the spring assists in maintaining the seal, even when the flow of fluid is weak or inconsistent.

The seat of the valve is precision-machined to ensure that the disc can create a perfect seal, preventing any leakage when the valve is closed. This seal is crucial for maintaining system integrity and preventing damage to equipment downstream.

3. Operation Principles

The operation of a DIN Cast Steel Straight Type Spring Loaded SDNR Globe Check Valve is quite simple, yet effective. It works on the basic principle of controlling the direction of flow in a pipeline. When the fluid or gas enters the valve from the inlet, it forces the valve disc to lift, allowing the fluid to flow through the valve.

When the flow pressure decreases or reverses, the spring-loaded mechanism comes into play, pushing the valve disc back to the closed position to prevent reverse flow. The spring-loaded design allows the valve to operate quickly and with minimal effort, even in systems with fluctuating pressure or low-flow conditions.

In case of system pressure failure or reduced flow, the valve ensures that the backflow is stopped, protecting sensitive equipment, pumps, or other machinery downstream. This feature makes it a critical component in maintaining the safety and efficiency of industrial systems.

When the flow pressure decreases or reverses, the spring-loaded mechanism comes into play, pushing the valve disc back to the closed position to prevent reverse flow. The spring-loaded design allows the valve to operate quickly and with minimal effort, even in systems with fluctuating pressure or low-flow conditions.

In case of system pressure failure or reduced flow, the valve ensures that the backflow is stopped, protecting sensitive equipment, pumps, or other machinery downstream. This feature makes it a critical component in maintaining the safety and efficiency of industrial systems.

4. Applications

DIN Cast Steel Straight Type Spring Loaded SDNR Globe Check Valves are commonly found in a wide range of industries due to their robust performance and reliable operation. Some key applications include:

Oil and Gas Industry

In the oil and gas industry, these valves are used in pipelines, refineries, and offshore platforms to prevent backflow and ensure that the flow direction is maintained. The ability to handle high pressures and aggressive fluids makes them ideal for harsh environments such as oil exploration and transportation.

In the oil and gas industry, these valves are used in pipelines, refineries, and offshore platforms to prevent backflow and ensure that the flow direction is maintained. The ability to handle high pressures and aggressive fluids makes them ideal for harsh environments such as oil exploration and transportation.

Power Generation

In power plants, especially thermal and nuclear facilities, controlling the direction of steam or coolant flow is crucial for maintaining system stability. These valves ensure that steam or coolant does not flow backward, potentially causing damage to heat exchangers, turbines, or other critical equipment.

In power plants, especially thermal and nuclear facilities, controlling the direction of steam or coolant flow is crucial for maintaining system stability. These valves ensure that steam or coolant does not flow backward, potentially causing damage to heat exchangers, turbines, or other critical equipment.

Chemical Processing

The chemical industry requires valves that can withstand corrosive fluids and gases. The DIN cast steel material used in the SDNR Globe Check Valve ensures that it can handle aggressive chemicals and maintain long-term performance in challenging environments.

The chemical industry requires valves that can withstand corrosive fluids and gases. The DIN cast steel material used in the SDNR Globe Check Valve ensures that it can handle aggressive chemicals and maintain long-term performance in challenging environments.

Water Treatment

These valves are also used in water treatment plants, where controlling the flow of water or chemicals is essential for maintaining the treatment process. The valve ensures that reverse flow does not occur, preventing contamination or system failure.

These valves are also used in water treatment plants, where controlling the flow of water or chemicals is essential for maintaining the treatment process. The valve ensures that reverse flow does not occur, preventing contamination or system failure.

HVAC Systems

In HVAC (heating, ventilation, and air conditioning) systems, globe check valves are used to regulate the flow of air or water, preventing reverse flow that could damage the system or affect performance.

In HVAC (heating, ventilation, and air conditioning) systems, globe check valves are used to regulate the flow of air or water, preventing reverse flow that could damage the system or affect performance.

5. Advantages of DIN Cast Steel Straight Type Spring Loaded SDNR Globe Check Valves

Prevention of Backflow: The primary advantage of this valve is its ability to prevent backflow in the system, ensuring that fluids only flow in one direction. This is vital for protecting sensitive equipment downstream.

Durability and Strength: The cast steel body ensures that the valve can withstand high pressures, high temperatures, and aggressive environments. It is resistant to corrosion, erosion, and wear, ensuring a long service life.

Spring-Loaded Mechanism: The spring-loaded design makes the valve more responsive and reliable. It allows the valve to function effectively even in low-flow or fluctuating pressure conditions, which is common in many industrial applications.

Energy Efficiency: The straight-type design minimizes pressure loss, resulting in energy savings and improved system efficiency.

Versatility: These valves are suitable for a variety of applications, including liquids, gases, and steam, making them highly versatile for different industrial systems.