0102030405

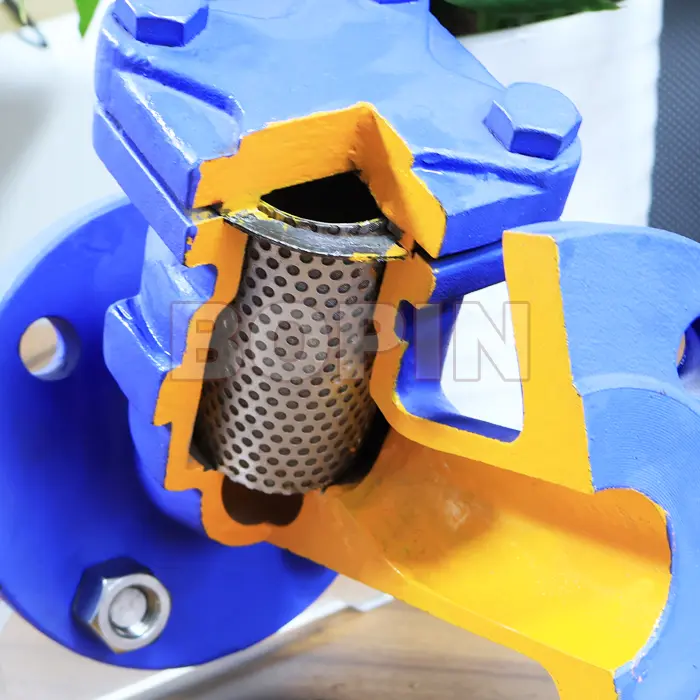

DIN GS-C25 Y Pattern Strainer

Understanding Y Pattern Strainer

A Y-pattern strainer is a type of filter that is typically installed in pipelines to remove particles, dirt, and other impurities from the flow of fluid. The strainer operates by using a mesh or perforated element to trap solid particles while allowing the clean fluid to flow through. The Y-pattern refers to the specific shape of the strainer body, which resembles the letter "Y" and allows for easy installation and maintenance.

The DIN GS-C25 designation refers to the material specification and standard used in the construction of the strainer. GS-C25 is a type of cast steel that adheres to the German DIN (Deutsches Institut für Normung) standards, a widely recognized set of standards that govern the design, manufacturing, and testing of industrial components. The Y-pattern design itself is characterized by its angled configuration, which helps facilitate optimal flow and filtration while minimizing pressure drops.

About Material of Cast Steel GS-C25

The DIN GS-C25 material is a cast steel alloy, typically composed of

Carbon: Around 0.25% to 0.30%, contributing to the material's strength and hardness.

Manganese: Typically around 0.60% to 0.90%, which improves toughness and helps to increase resistance to wear and deformation.

Silicon: Present in small amounts (around 0.30%) to improve casting properties and resistance to oxidation.

Phosphorus and Sulfur: These elements are kept to a minimum to avoid brittleness.

The GS-C25 material is known for its:

Strength: Provides sufficient strength to withstand high pressure and mechanical stress, making it suitable for a wide range of pipeline applications.

Corrosion Resistance: It offers resistance to rust and corrosion, which is essential for strainer applications where exposure to fluids, moisture, and varying temperatures is common.

Durability: The material provides longevity in systems requiring minimal maintenance.

This high-quality cast steel material ensures that the Y-pattern strainer is both strong and durable, able to endure harsh operating conditions such as high pressures, fluctuating temperatures, and exposure to aggressive chemicals.

Design and Construction of the Y-Pattern Strainer

The Y-pattern design of the strainer plays a significant role in its functionality and effectiveness. Here’s an overview of the key design elements:

Y-Shape Body: The strainer's body is shaped like the letter "Y," which optimizes flow and allows for efficient filtration. The angled shape helps minimize flow resistance, reducing pressure drops and ensuring smooth fluid passage. The design also enables more compact installation in pipelines with limited space.

Inlet and Outlet Connections: The inlet and outlet of the Y-pattern strainer are typically flanged or threaded to allow easy connection to the pipeline. The flanged design ensures a secure, leak-proof seal when installed in a pipeline.

Filter Element: Inside the strainer body, a filtering element, often made of stainless steel mesh or perforated plates, is installed to capture solid particles. The filter mesh is available in different sizes, depending on the filtration requirements. The filter element is easily replaceable or cleanable, providing flexibility for maintenance.

Cover: The strainer is fitted with a cover that allows access to the filter element for cleaning, inspection, or replacement. The cover is usually bolted into place, ensuring that it remains secure under pressure.

Drain/Blow-off Valve: Some models come equipped with a drain or blow-off valve, which allows for the removal of accumulated debris or sediment from the strainer. This valve is especially useful for cleaning the strainer without the need to remove it from the pipeline.

Applications

The DIN GS-C25 Y Pattern Strainer is used in a wide variety of industries and applications, particularly where fluid filtration is crucial. Some of the common applications include:

Oil and Gas Industry

In the oil and gas industry, Y-pattern strainers are employed to filter crude oil, natural gas, and refined products in pipelines and equipment. Strainers protect sensitive equipment such as pumps, compressors, and valves from damage due to particles and debris in the fluid. They are used in upstream, midstream, and downstream operations.

Water Treatment and Distribution

Y-pattern strainers are also extensively used in water treatment plants and water distribution systems to filter out solid particles, sand, and other contaminants from potable and wastewater. The Y-pattern design is particularly beneficial for minimizing clogging in water treatment facilities.

Chemical and Petrochemical Plants

In chemical processing, where fluids are often corrosive, abrasive, or contain solid particles, strainers are crucial for preventing contamination of chemical products and protecting machinery. The GS-C25 material’s resistance to corrosion and wear makes it an excellent choice for these industries.

Food and Beverage Industry

In food and beverage production, the Y-pattern strainer is used to filter out any solid contaminants from liquids, ensuring product purity and maintaining the performance of equipment. Materials such as cast steel are chosen for their ability to be easily cleaned and their resistance to corrosion, which is crucial in this industry.

Power Generation

Power plants, particularly those that use water for cooling or steam generation, rely on Y-pattern strainers to filter debris from cooling water or other liquids that circulate through turbines, condensers, and pumps. Ensuring clean fluid flow helps prevent damage to critical components and optimizes plant efficiency.

Advantages

The DIN GS-C25 Y Pattern Strainer offers numerous advantages that make it a preferred choice for industrial filtration applications:

Efficient Filtration: The strainer effectively removes solid particles, debris, and contaminants from fluid, improving the performance and longevity of downstream equipment.

Low Pressure Drop: Due to its Y-pattern design, the strainer ensures minimal resistance to fluid flow, which helps maintain pressure stability and reduces energy costs in the system.

Durability: The cast steel construction and corrosion-resistant materials ensure that the strainer has a long service life, even in harsh environments.

Ease of Maintenance: The Y-pattern design allows for easy maintenance, including cleaning and replacement of the filter element. The strainer’s cover is accessible, which simplifies servicing and reduces downtime.

Compact Design: The compact size of the Y-pattern strainer makes it ideal for installations in tight spaces, where other types of strainers might not be suitable.

Versatility: These strainers can be used for a wide range of applications across multiple industries, from water treatment to oil and gas, making them highly versatile.

Maintenance of the Y Pattern Strainer

Regular maintenance of the Y-pattern strainer is essential to ensure optimal performance and extend the life of the equipment. Some key maintenance steps include:

Cleaning the Filter Element: Depending on the type of fluid being filtered, the strainer may require periodic cleaning. The filter element should be inspected and cleaned or replaced when it becomes clogged or damaged.

Inspecting for Corrosion: Regular inspections for signs of corrosion or wear, particularly in high-temperature or chemically aggressive environments, are necessary to prevent material degradation and ensure long-term durability.

Checking for Leaks: Ensure that all seals, gaskets, and flanged connections are tight and leak-free, as leaks can lead to system inefficiency and costly downtime.

Blow-off Valve Operation: If the strainer has a blow-off valve, it should be operated periodically to remove accumulated debris and prevent clogging.

The DIN GS-C25 Y Pattern Strainer is a highly effective and versatile filtration solution for industrial systems requiring fluid filtration. Its robust construction, efficient filtration capabilities, and minimal pressure drop make it an excellent choice for a wide range of applications, from oil and gas to water treatment and chemical processing. Made from high-quality cast steel, the strainer offers long-term durability and resistance to corrosion, ensuring reliable performance in demanding environments. With its ease of maintenance and compact design, the Y-pattern strainer continues to be a vital component in the smooth operation of many industries, protecting equipment and improving operational efficiency.