0102030405

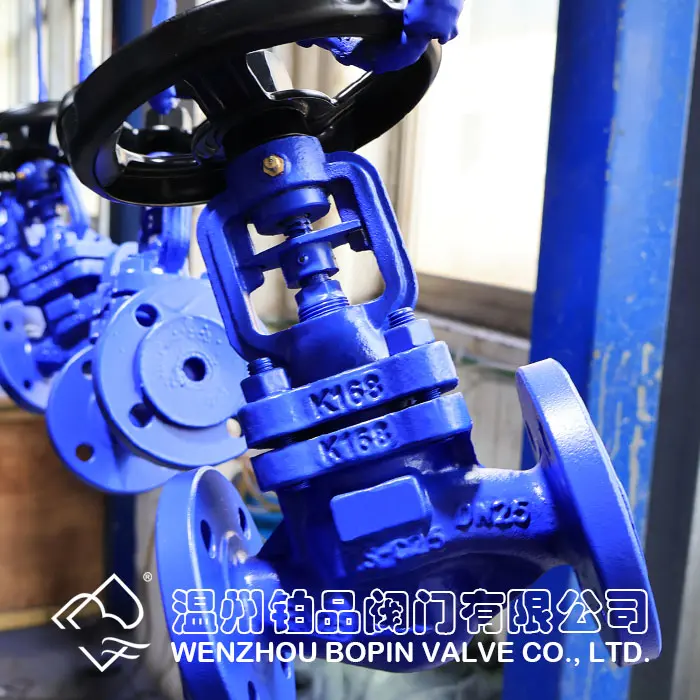

DIN GLOBE VALVE MANUFACTURER

1. Introduction of GS-C25 DIN Globe Valve

The GS-C25 DIN Globe Valve is a precision-engineered industrial valve designed for reliable throttling and shut-off applications in process piping systems. Manufactured according to the DIN (Deutsches Institut für Normung) standards, this valve is commonly used in oil and gas, petrochemical, power generation, chemical processing, water treatment, and general industrial systems where precise flow control and durability are essential.

Made from GS-C25, a carbon steel casting material equivalent to ASTM A216 WCB, the valve offers excellent mechanical strength, toughness, and temperature resistance. The combination of robust construction, tight shut-off capability, and compliance with DIN standards ensures dependable performance in both high- and low-pressure systems.

2. Construction and Design Features

The DIN Globe Valve design features a linear motion disc and seat arrangement, allowing the valve to regulate flow by moving the disc towards or away from the seat. Unlike gate valves that provide on/off control, globe valves are ideal for modulating flow, thanks to their superior throttling characteristics and flow regulation precision.

2.1 Body and Bonnet

The valve body and bonnet are manufactured from GS-C25 carbon steel, a material known for its high yield strength and resistance to mechanical stress. It performs well under moderate temperatures and pressures, making it suitable for steam, air, water, gas, and oil service. The body is precision-cast and machined to ensure dimensional accuracy and smooth flow passages that minimize turbulence and pressure loss.

A bolted bonnet design is typically adopted to allow easy maintenance and inspection. The bonnet is sealed using high-quality graphite or PTFE gaskets to prevent leakage even under cyclic temperature and pressure variations.

2.2 Trim

The internal components — including the disc, seat, and stem — are made from stainless steel (usually 13Cr or 304/316) or hard-faced with stellite for enhanced wear and corrosion resistance. The seat ring is either integral or renewable, depending on the valve size and application requirements.

The disc design may vary — plug type, parabolic, or flat — to meet specific control characteristics. The plug-type disc offers excellent throttling accuracy, while the flat disc ensures tight shut-off.

2.3 Stem and Packing

The stem is precision-machined and ground to ensure smooth operation with minimal friction. The packing gland uses graphite or PTFE rings that provide superior sealing performance and minimize emission leakage. A back-seat arrangement is provided in most designs, allowing the stem packing to be replaced while the valve is in full open position.

2.4 End Connections

The GS-C25 DIN Globe Valve typically features flanged ends conforming to DIN EN 1092-1 standards. Common pressure classes include PN16, PN25, and PN40, enabling compatibility with a wide range of pipeline systems. For specialized installations, butt-welded or socket-welded ends may also be supplied upon request.

2.5 Operation

Depending on valve size and service condition, the globe valve can be operated manually (handwheel), or fitted with electric, pneumatic, or hydraulic actuators for automated control. The rising stem design provides visual indication of valve position, while gear-operated mechanisms are used for larger diameters to reduce operator effort.

3. Working Principle

The GS-C25 DIN Globe Valve operates on a straightforward mechanism: the disc moves perpendicular to the seat to control flow. When the handwheel is rotated clockwise, the disc lowers and presses against the seat to stop flow. Conversely, counterclockwise rotation lifts the disc, allowing fluid to pass through the valve body.

The flow path is S-shaped and changes direction within the valve body, resulting in better throttling capability but slightly higher pressure loss compared to a gate valve. However, this design ensures accurate flow regulation, making globe valves a preferred choice in applications where flow control and tight shut-off are equally important.

4.Technical Specifications

Parameter Description

|

Design Standard |

DIN EN 13709 / DIN 3356 |

|

Face-to-Face Dimension |

DIN EN 558 Series 1 |

|

Pressure Rating |

PN16 / PN25 / PN40 |

|

Body Material |

GS-C25 (1.0619) Carbon Steel |

|

Bonnet Type |

Bolted Bonnet |

|

Trim Material |

13Cr / AISI 304 / AISI 316 / Stellite Faced |

|

Seat Type |

Renewable or Integral |

|

Disc Type |

Plug / Parabolic / Flat |

|

Stem Material |

Stainless Steel |

|

Gland Packing |

Graphite / PTFE |

|

End Connection Flanged |

(DIN EN 1092-1) |

|

Operation |

Manual / Electric / Pneumatic |

|

Working Temperature |

Up to 425°C (Depending on Trim and Sealing) |

|

Test Standard |

DIN EN 12266-1 / ISO 5208 |

5. Performance and Advantages

5.1 Precise Flow Control

The primary strength of a globe valve lies in its ability to regulate flow. The GS-C25 DIN Globe Valve provides fine throttling characteristics, making it ideal for process control systems that demand accurate flow adjustments.

5.2 Robust Pressure Integrity

The GS-C25 body material and high-quality seat design ensure the valve maintains tight shut-off under demanding pressure and temperature conditions. It delivers excellent sealing performance and leak-tight reliability even after repeated operation.

5.3 High Durability and Wear Resistance

With optional stellite hard-facing and stainless-steel trims, the valve is resistant to erosion, cavitation, and corrosion, ensuring long service life in aggressive environments.

5.4 Easy Maintenance

The bolted bonnet and renewable seat design facilitate easy disassembly, inspection, and part replacement without removing the valve from the pipeline. This reduces downtime and maintenance costs.

5.5 Versatility

The GS-C25 DIN Globe Valve can handle a wide range of media, including steam, oil, gas, condensate, and water, under both high and low pressure conditions. It can be installed in either horizontal or vertical pipelines, depending on flow direction and space constraints.

6. Applications

The GS-C25 DIN Globe Valve is widely used in:

Power Plants: Steam and condensate control lines

Refineries and Petrochemical Plants: Oil, fuel, and hydrocarbon service

Chemical Processing: Acid, alkali, and solvent lines (with appropriate trim selection)

HVAC Systems: Heating and cooling water regulation

Water Treatment: Flow and pressure control in clean and process water systems

Marine and Offshore: Engine cooling and ballast water systems

Power Plants: Steam and condensate control lines

Refineries and Petrochemical Plants: Oil, fuel, and hydrocarbon service

Chemical Processing: Acid, alkali, and solvent lines (with appropriate trim selection)

HVAC Systems: Heating and cooling water regulation

Water Treatment: Flow and pressure control in clean and process water systems

Marine and Offshore: Engine cooling and ballast water systems

Its combination of durability, flow precision, and compliance with international standards makes it a preferred valve type in both industrial and utility applications.

7. Installation and Maintenance Guidelines

Proper installation and maintenance are vital for ensuring long-term reliability.

Installation Direction:

Always install the valve so that the flow direction matches the arrow marked on the body, typically under the seat for standard globe valves.

Always install the valve so that the flow direction matches the arrow marked on the body, typically under the seat for standard globe valves.

Pipeline Alignment:

Ensure flanges are aligned to prevent stress on the valve body. Misalignment can lead to seat leakage and premature wear.

Ensure flanges are aligned to prevent stress on the valve body. Misalignment can lead to seat leakage and premature wear.

Torque Application:

Apply uniform torque to flange bolts and bonnet nuts to avoid uneven gasket compression.

Apply uniform torque to flange bolts and bonnet nuts to avoid uneven gasket compression.

Periodic Inspection:

Regularly check the stem packing and replace it if leakage is observed. Lubricate the stem threads periodically for smooth operation.

Seat Maintenance:

For valves with renewable seats, remove and reface or replace them when wear or pitting occurs.

For valves with renewable seats, remove and reface or replace them when wear or pitting occurs.

8. Compliance and Testing

Every GS-C25 DIN Globe Valve undergoes rigorous inspection and testing according to DIN EN 12266-1 and ISO 5208 standards, including:

Shell Test (Hydrostatic): To verify pressure-retaining capability.

Seat Leakage Test: To ensure tight shut-off.

Operational Test: To confirm smooth stem movement and functionality.

Visual and Dimensional Inspection: To verify material integrity and compliance with design standards.

Quality assurance processes are implemented throughout manufacturing to ensure that each valve meets both DIN and customer-specific requirements.

Shell Test (Hydrostatic): To verify pressure-retaining capability.

Seat Leakage Test: To ensure tight shut-off.

Operational Test: To confirm smooth stem movement and functionality.

Visual and Dimensional Inspection: To verify material integrity and compliance with design standards.

Quality assurance processes are implemented throughout manufacturing to ensure that each valve meets both DIN and customer-specific requirements.