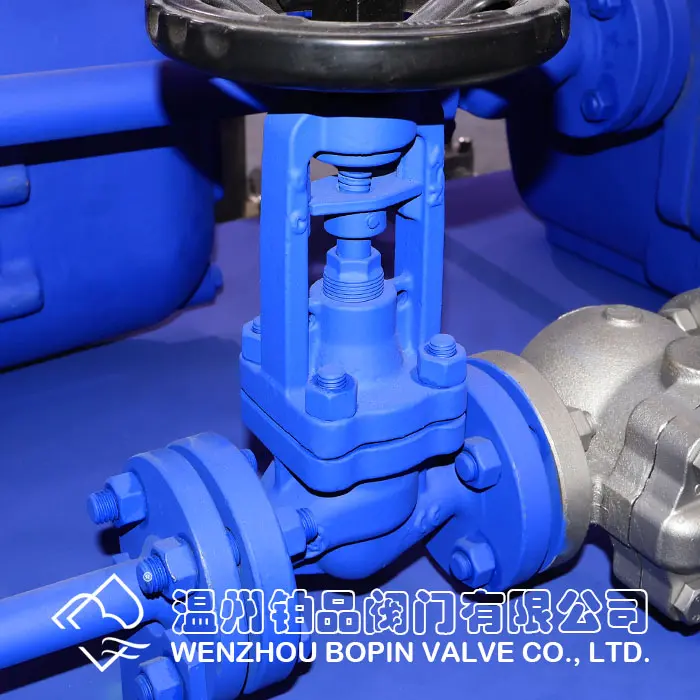

DIN BELLOWS SEALED GLOBE VALVE MANUFACTURER

1. Introduction

2. Design Standards and Compliance

|

Design standard |

DIN 3356 / EN 13709 |

|

Pressure-temperature ratings |

EN 12516-1 |

|

Flange connection standard |

EN 1092-1 (Form B1/B2) |

|

Face-to-face dimensions |

DIN 3202-F1 or EN 558 Series 1 |

|

Testing standard |

EN 12266-1 & 2 (hydraulic and leakage tests) |

|

Marking standard |

EN 19 |

3. Material Specifications

|

Carbon (C) |

0.25% |

|

Manganese (Mn) |

0.6–1.0% |

|

Silicon (Si) |

0.40% |

|

Phosphorus (P) |

≤ 0.035% |

|

Sulfur (S) |

≤ 0.035% |

|

Component: |

Material |

Specification |

|

Body |

GS-C25 |

DIN 17245 |

|

Bonnet |

GS-C25 |

DIN 17245 |

|

Bellows |

Stainless Steel 1.4541 / 1.4571 |

EN 10088 |

|

Stem |

Stainless Steel 1.4021 / 1.4057 |

EN 10088 |

|

Disc |

Stainless Steel with Hardfacing (Stellite) |

EN 10088 |

|

Seat Ring |

Stainless Steel / Stellite Overlay |

EN 10088 |

|

Gasket |

Graphite / Stainless Steel |

EN 1514-2 |

|

Handwheel |

Cast Iron / Ductile Iron |

EN-GJL-250 |

4. Bellows Sealing Design

Multi-ply stainless steel construction for flexibility and fatigue resistance.

Welded to both stem and bonnet, creating a completely sealed chamber.

Secondary packing (graphite) above the bellows provides a backup seal.

Helium leak testing ensures stem tightness.

Design life typically exceeds 10,000 cycles under rated conditions.

5. Structural Features

The body and bonnet are connected by bolted flanges with a precision-machined gasket groove. The use of spiral-wound graphite gaskets ensures reliable sealing even under thermal cycling.

The valve disc and seat are designed for linear throttling characteristics, providing excellent control accuracy and low pressure loss. The hardfaced trim extends service life under erosive conditions.

The stem is threaded and pinned to the disc, ensuring secure engagement while allowing self-alignment on the seat, improving sealing performance.

The ends are flanged according to EN 1092-1, available in pressure classes PN16, PN25, and PN40, ensuring easy installation and maintenance.

A rising stem and non-rotating handwheel design allows precise control of flow. For automated systems, the valve can also be equipped with electric or pneumatic actuators.

6. Applications

|

Pressure Class |

Max. Pressure (bar) |

Temperature Range (°C) |

|

PN16 |

16 bar |

-10°C to +300°C |

|

PN25 |

25 bar |

-10°C to +350°C |

|

PN40 |

40 bar |

-10°C to +400°C |

7. Working Principle

8. Advantages

The metal bellows provide a hermetic seal, preventing any emission through the stem—essential for handling toxic, flammable, or corrosive media.

The fatigue-resistant bellows can endure thousands of open-close cycles without failure.

Fully compliant with TA-Luft and ISO 15848 fugitive emission standards.

No need for frequent packing replacement or adjustment.

The GS-C25 body ensures high mechanical strength and temperature tolerance.

Flanged ends and standardized face-to-face dimensions simplify system integration.

Backup graphite packing ensures additional protection even if bellows are damaged.

Suitable for steam, condensate, gas, thermal oil, and aggressive chemical fluids.

9. Typical Applications

Chemical and Petrochemical Industries: Corrosive and toxic fluid control.

Oil & Gas: Refineries, storage, and transfer pipelines.

HVAC and District Heating Systems: Hot water and thermal oil circuits.

Pharmaceutical and Food Industries: Clean and inert gas control.

Paper and Pulp Mills: Steam and process fluid control in digesters and dryers.

10. Inspection and Testing

Shell pressure test: 1.5 × nominal pressure.

Seat leakage test: 1.1 × nominal pressure.

Bellows integrity test: Helium leak detection.

Functional test: Stem travel and torque verification.

Visual and dimensional inspection: As per EN 10204 3.1 certification.

All test results are recorded and traceable to the valve’s serial number, ensuring full product accountability.

11. Optional Features and Variants

Bellows materials: Inconel 625, Hastelloy C, or Monel for corrosive fluids.

Extended bonnet: For cryogenic or high-temperature service.

Drain or vent connections: For system maintenance.

Position indicators or limit switches: For remote monitoring.

Special coatings: Epoxy or zinc-phosphate for outdoor corrosion protection.

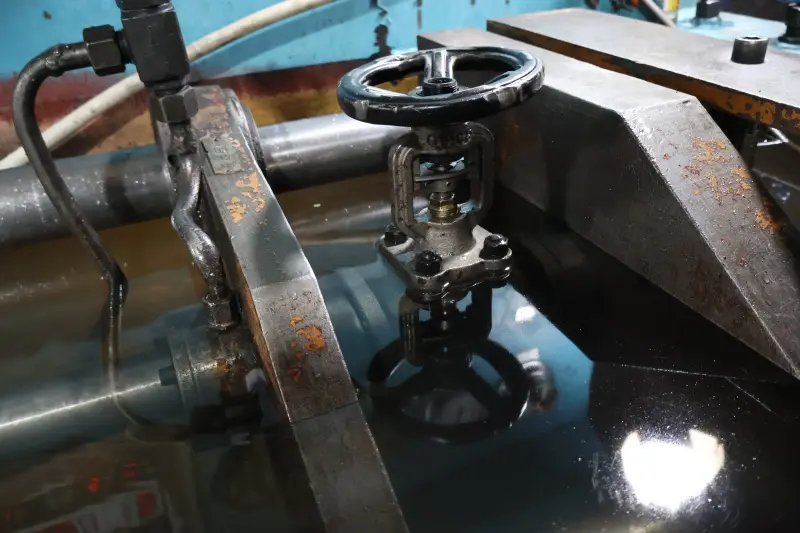

12. Maintenance and Service

Checking for external corrosion or gasket leaks.

Ensuring the bellows integrity through operational leak testing.