0102030405

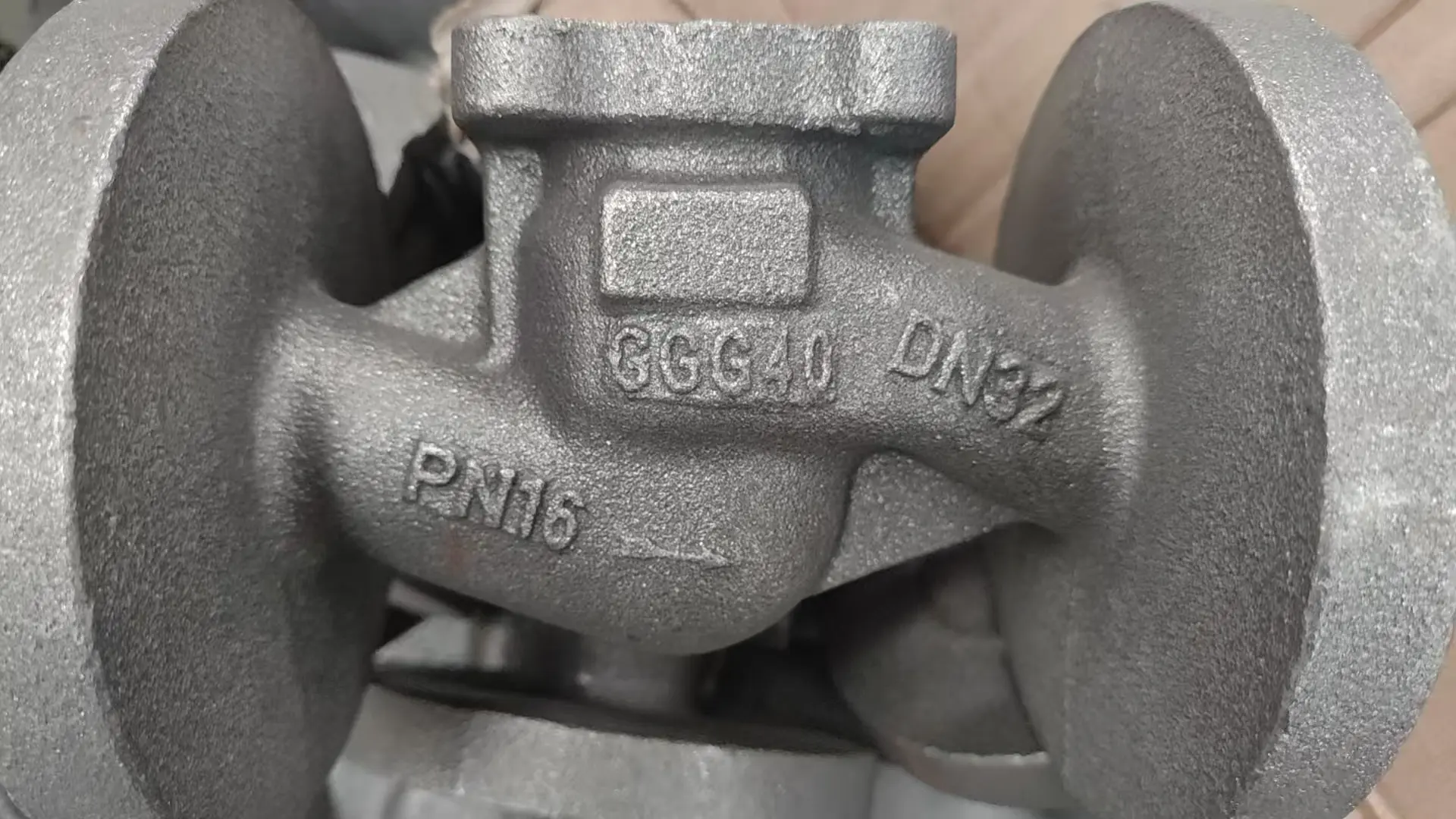

DIN 3356 Nodular Cast Iron GGG40 Bellows Sealed Globe Valve

Brief Introduction

DIN 3356 is a standard developed by the German Institute for Standardization. It specifies the technical requirements for globe valves used in various industrial applications. The DIN 3356 standard covers multiple materials, sizes, and configurations, but one specific variant is the Nodular Cast Iron GGG40 Bellows Sealed Globe Valve. These valves are designed to offer precision control over the flow of liquids and gases in piping systems.

Nodular cast iron (also known as ductile iron) is an alloy with enhanced mechanical properties due to its unique micro structure. When combined with a bellows seal, these valves provide an excellent solution for controlling high-pressure fluids in demanding industrial applications, such as those found in power plants, refineries, and chemical plants.

Nodular cast iron (also known as ductile iron) is an alloy with enhanced mechanical properties due to its unique micro structure. When combined with a bellows seal, these valves provide an excellent solution for controlling high-pressure fluids in demanding industrial applications, such as those found in power plants, refineries, and chemical plants.

Material Composition of Nodular Cast Iron GGG40

The term “GGG40” refers to a grade of nodular cast iron. The composition of GGG40 iron typically includes:

Carbon (C): 3.2% to 3.6%

Silicon (Si): 2.3% to 2.8%

Manganese (Mn): 0.3% to 0.7%

Magnesium (Mg): 0.03% to 0.05%

Sulfur (S) & Phosphorus (P): Minimal levels, below 0.02% each

The unique nodular structure of this material gives the valve superior strength, ductility, and resistance to wear and corrosion. These properties are essential for valves that operate under high pressure and temperature, ensuring a longer service life and minimal maintenance.

Carbon (C): 3.2% to 3.6%

Silicon (Si): 2.3% to 2.8%

Manganese (Mn): 0.3% to 0.7%

Magnesium (Mg): 0.03% to 0.05%

Sulfur (S) & Phosphorus (P): Minimal levels, below 0.02% each

The unique nodular structure of this material gives the valve superior strength, ductility, and resistance to wear and corrosion. These properties are essential for valves that operate under high pressure and temperature, ensuring a longer service life and minimal maintenance.

Role of Bellows in Sealing

Bellows seals are used in globe valves to prevent leakage at the stem. The bellows, made of a flexible material such as stainless steel or a high-performance alloy, create a reliable barrier to prevent leakage of process fluids. The benefits of bellows-sealed valves include:

Leak-Free Operation: Bellows seals eliminate the need for traditional packing, which can wear out over time and cause leaks. This makes bellows-sealed valves ideal for applications where leakage could be hazardous, such as in toxic or corrosive fluid handling.

Longer Service Life: The flexible nature of the bellows allows for the repeated motion of the valve stem without compromising the seal. This greatly extends the life of the valve, reducing maintenance and replacement costs.

Improved Safety: By maintaining a tight seal, bellows-sealed valves help prevent fugitive emissions, which are not only a safety hazard but also an environmental concern.

Reduced Friction: Bellows eliminate the need for stem packing, reducing friction and the associated wear on the valve components.

Leak-Free Operation: Bellows seals eliminate the need for traditional packing, which can wear out over time and cause leaks. This makes bellows-sealed valves ideal for applications where leakage could be hazardous, such as in toxic or corrosive fluid handling.

Longer Service Life: The flexible nature of the bellows allows for the repeated motion of the valve stem without compromising the seal. This greatly extends the life of the valve, reducing maintenance and replacement costs.

Improved Safety: By maintaining a tight seal, bellows-sealed valves help prevent fugitive emissions, which are not only a safety hazard but also an environmental concern.

Reduced Friction: Bellows eliminate the need for stem packing, reducing friction and the associated wear on the valve components.

Design Features of GGG40 Bellows Sealed Globe Valve

A GGG40 bellows-sealed globe valve follows a specific design to ensure optimal performance in demanding applications. Here are the key features of the valve:

Globe Valve Design: The globe valve design, characterized by a linear motion of the stem, is ideal for precise throttling and flow regulation. The flow through the valve body is directed in a straight line, minimizing pressure drops and ensuring smoother flow control.

Nodular Cast Iron Body: The valve body is made of GGG40 nodular cast iron, which provides a combination of strength and ductility. The material is resistant to thermal expansion, and the unique structure allows for excellent resistance to both fatigue and corrosion.

Bellows Seal: The bellows are typically located around the valve stem, creating a hermetic seal to prevent fluid leakage. The bellows are designed to withstand both the mechanical stresses of valve operation and the harsh chemical environments often encountered in industrial processes.

Bonnet Construction: The valve bonnet, which houses the bellows, is designed to protect the seal from external damage and maintain pressure integrity. The bonnet is typically bolted to the valve body, ensuring a secure and reliable connection.

Seat and Disc: The valve seat and disc are typically made of materials like stainless steel, ensuring a reliable sealing surface for a tight shut-off. The seat design is precision-engineered to prevent erosion and damage from aggressive fluids.

Stem Design: The stem is designed for smooth movement to allow for easy adjustment of the valve position. The stem’s connection to the bellows is made in a way that minimizes wear and tear over time.

Actuation Options: DIN 3356 bellows-sealed globe valves can be actuated manually or with a pneumatic or electric actuator, depending on the application. Automated versions are especially useful in systems where precise, frequent adjustments are required.

Globe Valve Design: The globe valve design, characterized by a linear motion of the stem, is ideal for precise throttling and flow regulation. The flow through the valve body is directed in a straight line, minimizing pressure drops and ensuring smoother flow control.

Nodular Cast Iron Body: The valve body is made of GGG40 nodular cast iron, which provides a combination of strength and ductility. The material is resistant to thermal expansion, and the unique structure allows for excellent resistance to both fatigue and corrosion.

Bellows Seal: The bellows are typically located around the valve stem, creating a hermetic seal to prevent fluid leakage. The bellows are designed to withstand both the mechanical stresses of valve operation and the harsh chemical environments often encountered in industrial processes.

Bonnet Construction: The valve bonnet, which houses the bellows, is designed to protect the seal from external damage and maintain pressure integrity. The bonnet is typically bolted to the valve body, ensuring a secure and reliable connection.

Seat and Disc: The valve seat and disc are typically made of materials like stainless steel, ensuring a reliable sealing surface for a tight shut-off. The seat design is precision-engineered to prevent erosion and damage from aggressive fluids.

Stem Design: The stem is designed for smooth movement to allow for easy adjustment of the valve position. The stem’s connection to the bellows is made in a way that minimizes wear and tear over time.

Actuation Options: DIN 3356 bellows-sealed globe valves can be actuated manually or with a pneumatic or electric actuator, depending on the application. Automated versions are especially useful in systems where precise, frequent adjustments are required.

Advantages of Using GGG40 Bellows Sealed Globe Valves

Corrosion Resistance: Nodular cast iron is resistant to many forms of corrosion, making it suitable for a wide range of aggressive fluids. This is particularly important in chemical, petrochemical, and marine industries where exposure to harsh chemicals is common.

Pressure and Temperature Tolerance: The GGG40 material offers good performance in high-pressure and high-temperature environments. It maintains its mechanical properties even at elevated temperatures, making it suitable for steam, hot water, and pressurized gas applications.

Leak-Free Operation: The bellows-sealed design ensures that there are no leaks along the valve stem. This is particularly important in industries that handle dangerous or corrosive materials, where even a minor leak can pose significant safety risks.

Durability: The durability of GGG40 nodular cast iron combined with the bellows seal ensures a long service life. These valves can withstand frequent cycling and extended operation without needing frequent maintenance or replacement.

Low Maintenance: The bellows seal requires minimal maintenance compared to traditional packing systems. As bellows do not degrade over time as packing does, the need for re-packing or tightening the stem is greatly reduced.

Precise Control: The globe valve design ensures precise control of flow rates, making these valves ideal for regulating fluids in systems requiring accurate control, such as HVAC systems, chemical processes, or water treatment plants.

Pressure and Temperature Tolerance: The GGG40 material offers good performance in high-pressure and high-temperature environments. It maintains its mechanical properties even at elevated temperatures, making it suitable for steam, hot water, and pressurized gas applications.

Leak-Free Operation: The bellows-sealed design ensures that there are no leaks along the valve stem. This is particularly important in industries that handle dangerous or corrosive materials, where even a minor leak can pose significant safety risks.

Durability: The durability of GGG40 nodular cast iron combined with the bellows seal ensures a long service life. These valves can withstand frequent cycling and extended operation without needing frequent maintenance or replacement.

Low Maintenance: The bellows seal requires minimal maintenance compared to traditional packing systems. As bellows do not degrade over time as packing does, the need for re-packing or tightening the stem is greatly reduced.

Precise Control: The globe valve design ensures precise control of flow rates, making these valves ideal for regulating fluids in systems requiring accurate control, such as HVAC systems, chemical processes, or water treatment plants.

Applications of GGG40 Bellows Sealed Globe Valves

Chemical and Petrochemical Industry: The valve is highly suitable for controlling aggressive chemicals in refineries, chemical plants, and gas processing facilities. Its ability to maintain leak-free operation makes it an ideal choice for hazardous fluid handling.

Power Plants: Bellows-sealed globe valves are commonly used in power plants to control steam and water flow in high-pressure systems. The durable material and design make these valves ideal for power generation applications.

Water Treatment: These valves are used to regulate water and wastewater flow in treatment plants. Their corrosion resistance is essential for handling various water qualities.

Marine Industry: GGG40 bellows-sealed globe valves are also used in marine applications, where resistance to saltwater corrosion and reliable sealing are critical.

HVAC Systems: In HVAC systems, controlling the flow of heating and cooling fluids is vital for efficiency. Bellows-sealed globe valves provide precise control and eliminate the risk of leaks in sensitive environments.

Power Plants: Bellows-sealed globe valves are commonly used in power plants to control steam and water flow in high-pressure systems. The durable material and design make these valves ideal for power generation applications.

Water Treatment: These valves are used to regulate water and wastewater flow in treatment plants. Their corrosion resistance is essential for handling various water qualities.

Marine Industry: GGG40 bellows-sealed globe valves are also used in marine applications, where resistance to saltwater corrosion and reliable sealing are critical.

HVAC Systems: In HVAC systems, controlling the flow of heating and cooling fluids is vital for efficiency. Bellows-sealed globe valves provide precise control and eliminate the risk of leaks in sensitive environments.