0102030405

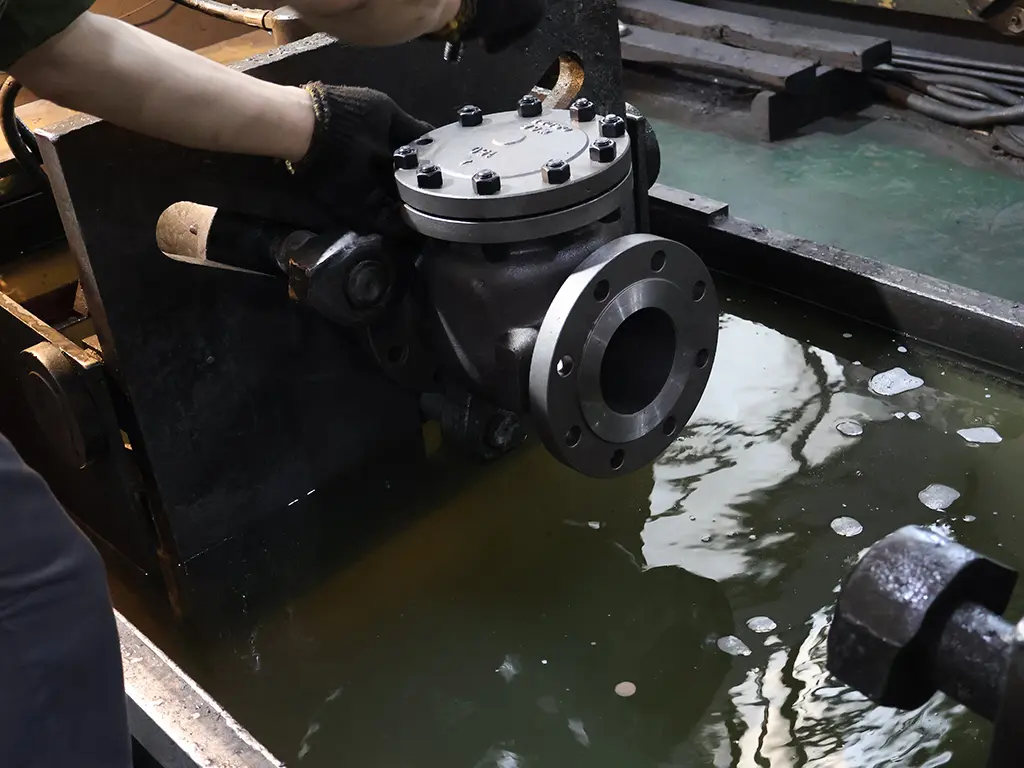

BS 1868 Cast Steel Flange RF End Swing Check Valve

Overview of BS 1868 Standards

The BS 1868 standard refers to the specifications for cast steel flange end swing check valves. BS 1868 outlines the requirements for the design, materials, and testing of these valves. This British Standard, published by the British Standards Institution (BSI), ensures that valves conform to internationally recognized quality and performance criteria.

Key features of BS 1868 Standard: Material Specifications: The valve body is made from high-quality cast steel, ensuring robustness and durability in various applications.

Flange End Connections: The valve has flange connections, which are used for easy installation and maintenance. These flanges comply with the appropriate flange standards, such as RF (Raised Face), to ensure a secure seal.

Swing Check Mechanism: The valve utilizes a swing-type mechanism, where a disc swings open or closed based on the direction of flow. This design offers reliable operation, especially in systems with intermittent flow.

Key features of BS 1868 Standard: Material Specifications: The valve body is made from high-quality cast steel, ensuring robustness and durability in various applications.

Flange End Connections: The valve has flange connections, which are used for easy installation and maintenance. These flanges comply with the appropriate flange standards, such as RF (Raised Face), to ensure a secure seal.

Swing Check Mechanism: The valve utilizes a swing-type mechanism, where a disc swings open or closed based on the direction of flow. This design offers reliable operation, especially in systems with intermittent flow.

Design and Construction

The BS 1868 Cast Steel Flange RF End Swing Check Valve features several key design elements:

Body: Typically, the valve body is cast from high-quality carbon steel or alloy steel, depending on the application’s temperature and pressure conditions. The cast body ensures strength and resistance to fatigue and corrosion.

Disc: The disc is the most critical component of the swing check valve. It swings to allow flow in the desired direction and closes automatically when the flow reverses. The disc may be made from materials such as stainless steel or other corrosion-resistant alloys.

Hinge and Pin: The disc is attached to the body via a hinge and pin. The hinge allows the disc to swing open or shut based on the direction of flow.

Flange Ends: The valve is designed with raised face flange (RF) connections. This provides a sturdy, leak-proof seal when bolted to adjacent piping, ensuring that the valve remains securely in place during operation.

Body: Typically, the valve body is cast from high-quality carbon steel or alloy steel, depending on the application’s temperature and pressure conditions. The cast body ensures strength and resistance to fatigue and corrosion.

Disc: The disc is the most critical component of the swing check valve. It swings to allow flow in the desired direction and closes automatically when the flow reverses. The disc may be made from materials such as stainless steel or other corrosion-resistant alloys.

Hinge and Pin: The disc is attached to the body via a hinge and pin. The hinge allows the disc to swing open or shut based on the direction of flow.

Flange Ends: The valve is designed with raised face flange (RF) connections. This provides a sturdy, leak-proof seal when bolted to adjacent piping, ensuring that the valve remains securely in place during operation.

Working Principle

The swing check valve operates on a very straightforward principle. It allows the fluid to flow in one direction and automatically prevents reverse flow. The movement of the disc is controlled by the fluid’s pressure and velocity:

Forward Flow: When the flow is in the desired direction, the fluid pressure pushes the valve disc away from the seat, allowing the fluid to pass through.

Reverse Flow: If the flow reverses, the disc swings back into place, sealing the opening and preventing backflow. This action is triggered by the pressure differential between the two sides of the disc.

Forward Flow: When the flow is in the desired direction, the fluid pressure pushes the valve disc away from the seat, allowing the fluid to pass through.

Reverse Flow: If the flow reverses, the disc swings back into place, sealing the opening and preventing backflow. This action is triggered by the pressure differential between the two sides of the disc.

Applications

Swing check valves are essential in various industrial systems, where preventing backflow is crucial for maintaining operational safety, protecting equipment, and ensuring system efficiency.

Power Generation In power plants, swing check valves are used to prevent backflow in steam, water, and fuel lines. Backflow in these systems could cause significant damage to turbines, boilers, or other vital components. These valves help to ensure that the flow direction is strictly maintained.

Water and Wastewater Treatment In water treatment plants, these valves are employed to avoid the backflow of treated water into the incoming supply. In wastewater systems, they prevent contaminants from flowing back into the treatment process.

Oil and Gas Swing check valves are widely used in the oil and gas industry to protect pipelines, storage tanks, and other equipment. By ensuring that the flow of oil or gas only goes in the desired direction, these valves prevent the risk of damage to downstream systems caused by backflow or pressure surges.

Chemical Processing In chemical plants, the presence of hazardous or corrosive chemicals makes the integrity of the pipeline system critical. Swing check valves prevent chemicals from flowing back and contaminating other parts of the system.

Power Generation In power plants, swing check valves are used to prevent backflow in steam, water, and fuel lines. Backflow in these systems could cause significant damage to turbines, boilers, or other vital components. These valves help to ensure that the flow direction is strictly maintained.

Water and Wastewater Treatment In water treatment plants, these valves are employed to avoid the backflow of treated water into the incoming supply. In wastewater systems, they prevent contaminants from flowing back into the treatment process.

Oil and Gas Swing check valves are widely used in the oil and gas industry to protect pipelines, storage tanks, and other equipment. By ensuring that the flow of oil or gas only goes in the desired direction, these valves prevent the risk of damage to downstream systems caused by backflow or pressure surges.

Chemical Processing In chemical plants, the presence of hazardous or corrosive chemicals makes the integrity of the pipeline system critical. Swing check valves prevent chemicals from flowing back and contaminating other parts of the system.

Advantages of the BS 1868 Cast Steel Flange RF End Swing Check Valve

The BS 1868 Cast Steel Flange RF End Swing Check Valve offers numerous advantages:

Reliable Performance Swing check valves are known for their reliable performance in a variety of service conditions. The simple, mechanical operation of the valve ensures that it functions well in both high and low-pressure systems.

Durability The use of cast steel provides excellent durability, making the valve highly resistant to wear, corrosion, and thermal stress. This ensures long-term reliability and reduces the need for frequent maintenance.

Compact and Cost-Effective Swing check valves are relatively compact compared to other types of check valves (such as lift or dual plate check valves). They are cost-effective, especially for systems with lower to moderate flow rates and pressures.

Low Maintenance Due to their straightforward design, these valves require relatively low maintenance. The components (disc, hinge, and seat) experience minimal wear, and the valve body itself is resistant to many forms of corrosion.

Smooth Operation The swing motion of the valve disc allows for smooth operation with minimal resistance. This helps to reduce the energy required to operate the system and minimizes any impact on the overall system performance.

Reliable Performance Swing check valves are known for their reliable performance in a variety of service conditions. The simple, mechanical operation of the valve ensures that it functions well in both high and low-pressure systems.

Durability The use of cast steel provides excellent durability, making the valve highly resistant to wear, corrosion, and thermal stress. This ensures long-term reliability and reduces the need for frequent maintenance.

Compact and Cost-Effective Swing check valves are relatively compact compared to other types of check valves (such as lift or dual plate check valves). They are cost-effective, especially for systems with lower to moderate flow rates and pressures.

Low Maintenance Due to their straightforward design, these valves require relatively low maintenance. The components (disc, hinge, and seat) experience minimal wear, and the valve body itself is resistant to many forms of corrosion.

Smooth Operation The swing motion of the valve disc allows for smooth operation with minimal resistance. This helps to reduce the energy required to operate the system and minimizes any impact on the overall system performance.

Installation and Maintenance

Installation

Installation of a BS 1868 Cast Steel Flange RF End Swing Check Valve is straightforward, but a few key considerations must be observed:

Orientation: The valve must be installed in the correct orientation to ensure proper operation. The direction of flow should align with the arrow on the valve body.

Flange Connections: The flange ends of the valve are bolted to the adjacent pipework, and gaskets are used to ensure a leak-free connection.

Proper Sizing:The valve must be properly sized to match the flow characteristics of the system, including pressure, temperature, and flow rate.

Maintenance Swing check valves are relatively low maintenance, but regular inspection and care are essential to ensure they continue to operate effectively:

Inspection: Regularly inspect the valve for wear, especially the hinge pin and disc, to ensure there are no signs of corrosion or mechanical failure.

Cleaning: Periodically clean the valve seat and disc to prevent debris build-up, which could interfere with the valve's operation.

Lubrication: Lubricate the hinge and pin to minimize wear and ensure smooth operation.

Orientation: The valve must be installed in the correct orientation to ensure proper operation. The direction of flow should align with the arrow on the valve body.

Flange Connections: The flange ends of the valve are bolted to the adjacent pipework, and gaskets are used to ensure a leak-free connection.

Proper Sizing:The valve must be properly sized to match the flow characteristics of the system, including pressure, temperature, and flow rate.

Maintenance Swing check valves are relatively low maintenance, but regular inspection and care are essential to ensure they continue to operate effectively:

Inspection: Regularly inspect the valve for wear, especially the hinge pin and disc, to ensure there are no signs of corrosion or mechanical failure.

Cleaning: Periodically clean the valve seat and disc to prevent debris build-up, which could interfere with the valve's operation.

Lubrication: Lubricate the hinge and pin to minimize wear and ensure smooth operation.

Common Issues and Troubleshooting

While swing check valves are generally reliable, some common issues may arise, including:

Disc Wear: Over time, the disc may wear, preventing it from sealing properly. This can result in leakage and loss of backflow protection.

Corrosion: In systems with aggressive fluids, the valve may corrode, particularly at the disc, seat, or hinge areas. This can lead to poor performance.

Valve Sealing Issues: If the valve does not close fully due to debris or mechanical failure, it can cause leaks and reverse flow.

Regular maintenance and timely replacement of worn parts can help to mitigate these issues.

Disc Wear: Over time, the disc may wear, preventing it from sealing properly. This can result in leakage and loss of backflow protection.

Corrosion: In systems with aggressive fluids, the valve may corrode, particularly at the disc, seat, or hinge areas. This can lead to poor performance.

Valve Sealing Issues: If the valve does not close fully due to debris or mechanical failure, it can cause leaks and reverse flow.

Regular maintenance and timely replacement of worn parts can help to mitigate these issues.