+86 19720579616

+86 19720579616

Zalo

Zalo

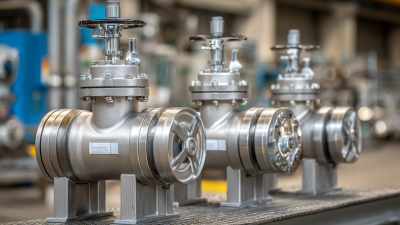

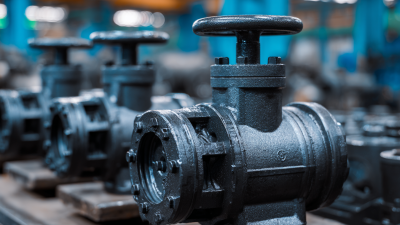

The global valve market is witnessing significant growth, driven by technological advancements and the demand for efficient fluid control systems across various industries. Among the diverse range of valves, Din Bellows Sealed Globe Valves stand out due to their robust design and exceptional sealing capabilities, which effectively prevent leakage and ensure operational reliability. According to a recent report by MarketsandMarkets, the valve market is projected to reach USD 94.75 billion by 2025, with a notable rise in the adoption of valves that cater to stringent safety and environmental standards. Industries such as petrochemical, power generation, and water treatment are increasingly relying on Din Bellows Sealed Globe Valves for their unique applications, which enhance process efficiency and minimize the risk of contamination. This blog will explore the innovative uses of these valves in various sectors and highlight their benefits in today's industrial landscape.

The unique benefits of DIN bellows sealed globe valves in chemical processing applications are becoming increasingly recognized due to their superior design and functionality. Unlike traditional valve types, bellows sealed globe valves provide a robust barrier against leakage, making them ideal for handling aggressive chemicals and hazardous materials. According to a report by the Global Valve Market Analysis, the demand for valves in the chemical industry is projected to grow at a CAGR of 5.2% from 2021 to 2027, highlighting the need for advanced sealing solutions like those offered by bellows sealed designs.

Furthermore, these valves are particularly suitable for high-pressure applications where maintaining integrity is critical. The use of bellows technology not only minimizes the risk of external contamination but also enhances the operational efficiency by reducing the need for frequent maintenance. Research from the Valve Manufacturers Association indicates that almost 25% of valve failures in chemical processing are due to leakages. Thus, incorporating DIN bellows sealed globe valves can significantly mitigate such risks, leading to improved safety and reliability in chemical processing plants. The integration of these valves is essential for companies looking to optimize their operations while adhering to stringent environmental regulations.

Din Bellows Sealed Globe Valves play a vital role in enhancing energy efficiency in power plants, including nuclear facilities like the Zaporizhzhya Nuclear Power Plant in Ukraine. These valves are designed to minimize leakage and reduce the risk of contamination, making them ideal for applications where safety and reliability are paramount. By maintaining tighter seals, these valves ensure that energy losses during operation are significantly decreased, which directly contributes to improved overall efficiency and sustainability in energy production.

Tips for selecting Din Bellows Sealed Globe Valves for your facility include considering the operating pressure and temperature requirements, as well as the specific fluid characteristics. Proper sizing and material selection can further improve the longevity and performance of these valves. Additionally, regular maintenance inspections are crucial to ensure that the seals remain effective and that the valves continue to operate at peak efficiency.

In the context of advanced systems such as molten salt test loops, incorporating Din Bellows Sealed Globe Valves can facilitate better flow management and pressure control. This strategic integration helps optimize energy transfer within the system, showcasing the significant impact that these valves have in both existing operations and future energy solutions.

| Industry | Specific Application | Impact on Energy Efficiency | Maintenance Requirements |

|---|---|---|---|

| Power Generation | Steam Control in Turbines | Reduces steam loss, increasing overall plant efficiency by 3-5% | Periodic inspection and seal replacement |

| Water Treatment | Chemical Dosing Control | Optimizes chemical use, improving energy efficiency in filtration processes | Regular checks on valve integrity |

| Oil & Gas | Flow Regulation in Pipelines | Enhances control leading to reduced pumping energy consumption | Routine maintenance and testing |

| Food Processing | Liquid Transfer Control | Increases energy efficiency by ensuring optimal flow rates | Inspection for wear and cleanliness checks |

| Chemical Manufacturing | Reactor Pressure Control | Maintains optimal temperature and pressure, enhancing energy savings | Scheduled maintenance and calibration |

In the pharmaceutical manufacturing sector, maintaining the integrity and purity of products is of utmost importance. Din bellows sealed globe valves play a crucial role in achieving these standards by providing a reliable solution for controlling the flow of fluids while minimizing contamination risks. The innovative design of these valves features a bellows seal that effectively avoids media leaks, thereby ensuring that no external substances interfere with the manufacturing process. This is particularly essential in applications that involve sensitive compounds or sterile environments, where even the slightest contamination can compromise product quality.

Moreover, the use of Din bellows sealed globe valves enhances operational efficiency within pharmaceutical facilities. Their robust construction allows for precise throttling and flow control, which is vital in maintaining optimal conditions for various processes, such as the mixing and transportation of active pharmaceutical ingredients (APIs). Furthermore, these valves require less maintenance than traditional valve types due to their sealed design, resulting in reduced downtime and increased productivity. As the pharmaceutical industry continues to evolve and prioritize safety, the adoption of such innovative valve solutions becomes increasingly indispensable.

In the realm of water treatment facilities, DIN bellows sealed globe valves play a crucial role in ensuring the efficiency and reliability of various processes. These valves are designed to maintain a tight seal, preventing leaks and minimizing contamination, which is vital in water treatment applications. The bellows design provides a significant advantage, as it accommodates thermal expansion and contraction while also protecting the valve’s stem from direct exposure to harsh media. This feature not only prolongs the service life of the valve but also contributes to enhanced operational safety in water management systems.

As water treatment facilities strive to meet increasing regulatory standards and performance demands, the implementation of advanced valve technologies becomes imperative. DIN bellows sealed globe valves offer improved flow control and reduced maintenance requirements, making them a preferred choice for engineers seeking reliable solutions. Their adaptability across various operational scenarios, from filtration to chemical dosing, underscores their importance in contemporary water treatment infrastructure. By leveraging these innovative valves, facilities can achieve superior performance, ultimately leading to better water quality and sustainability in the management of vital water resources.

The oil and gas industry has seen a significant shift towards the adoption of Din bellows sealed globe valves due to their superior performance and reliability compared to traditional valves. Conventional valves are often prone to leakages under high-pressure conditions, which can lead to safety and environmental hazards. In contrast, Din bellows sealed globe valves are designed with a flexible bellows system that effectively prevents leakage, making them an ideal choice for critical applications where strict fluid control is essential.

According to industry reports, the global automotive valve market is projected to reach a value of $1117.2 million by 2025 and is expected to experience a compound annual growth rate (CAGR) of 1.8%, reaching $1288.6 million by 2033. This growth highlights a rising demand for advanced valve technologies, including Din bellows sealed globe valves, that enhance operational efficiency and minimize maintenance costs. The unique sealing mechanism not only provides a reliable solution for harsh environments but also contributes to extending the lifespan of valve systems in various applications, particularly in the ever-evolving oil and gas sector.