+86 19720579616

+86 19720579616

Zalo

Zalo

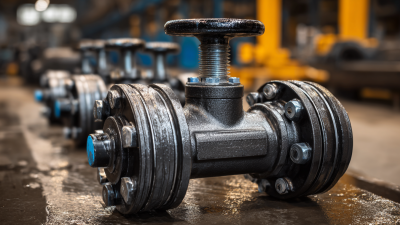

In the ever-evolving landscape of industrial components, Din Gate Valves emerge as a fundamental element in ensuring seamless fluid control and management across various applications. As we approach 2025, the demand for high-quality, reliable, and efficient valve solutions has intensified, leading manufacturers to innovate and refine their offerings to meet the exacting standards of modern industry. This guide delves into the top 5 Din Gate Valves that stand out in terms of unmatched quality and performance, setting a new benchmark for excellence in the market.

As industries worldwide place greater emphasis on sustainability, energy efficiency, and performance, selecting the right Din Gate Valves becomes paramount. The advancements in materials, design, and technology have given rise to products that not only excel in functionality but also contribute to reduced operational costs and extended service life. In this comprehensive overview, we will examine the leading contenders for 2025, highlighting their features, advantages, and application scenarios, empowering decision-makers to make informed choices that enhance their operations. Prepare to explore the future of Din Gate Valves and discover how these exemplary products can elevate your systems to new heights of performance and reliability.

When selecting DIN gate valves for optimal performance in 2025, certain key features should be prioritized to ensure unmatched quality. First and foremost, materials and construction integrity are critical. Look for valves made from high-grade materials, such as stainless steel or corrosion-resistant alloys, which guarantee durability and longevity. The valve's design should include dependable sealing mechanisms to prevent leaks under pressure, making them suitable for various industrial applications.

In addition to material quality, attention should be given to the valve's flow characteristics. A well-engineered DIN gate valve will offer minimal flow resistance, ensuring efficiency in fluid transport. Features such as smooth disc movement and tight shut-off capacities enhance service reliability. Furthermore, ease of installation and maintenance is vital; valves designed for simple disassembly contribute to lower operational costs and enhance user experience, making them a smart choice for both manufacturers and operators alike.

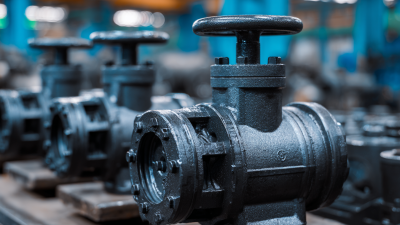

When assessing the leading DIN gate valves for 2025, performance metrics are pivotal in determining their operational efficiency and suitability for various applications. Key performance indicators such as flow coefficient (Cv), pressure drop, and temperature tolerance play crucial roles in comparative evaluations. Manufacturers are increasingly focusing on these metrics to enhance their products, ensuring that they not only meet industry standards but also exceed user expectations in challenging environments.

Additionally, the material composition and construction design significantly impact the overall functionality of gate valves. For example, valves made from high-grade stainless steel can withstand corrosive conditions, while innovative sealing technologies prevent leaks under high pressure. Recent studies have shown that valves incorporating advanced engineering techniques demonstrate improved reliability, making them preferred choices for critical installations. As we move towards 2025, understanding these performance metrics will be essential for engineers and procurement professionals when selecting the right DIN gate valve for their specific needs.

When evaluating the top DIN gate valves for 2025, the durability and material quality significantly impact both performance and longevity. According to a recent report by MarketResearchFuture, the global gate valve market is projected to reach $8.1 billion by 2025, driven by demand for robust and corrosion-resistant materials. Valves constructed from high-grade stainless steel and ductile iron are increasingly favored due to their ability to withstand extreme temperatures and pressures while maintaining structural integrity.

Furthermore, the use of advanced coatings and seal materials can enhance the lifespan of these valves. The 2023 Industry Trends Report indicates that valves with enhanced surface finishes and resistant linings reduce maintenance costs by up to 30% while ensuring reliable operation in various industrial applications. This focus on material quality not only elevates the overall performance of DIN gate valves but also aligns with the industry's shift towards sustainable practices, with manufacturers seeking to minimize waste and optimize resource use in their production processes.

| Valve Model | Material | Size (mm) | Pressure Rating (PN) | Durability (Cycles) | Temperature Range (°C) |

|---|---|---|---|---|---|

| Model A | Ductile Iron | 50 | 16 | 1,500,000 | -20 to 80 |

| Model B | Stainless Steel | 65 | 40 | 2,000,000 | -196 to 300 |

| Model C | Carbon Steel | 80 | 20 | 1,200,000 | -10 to 150 |

| Model D | Bronze | 100 | 25 | 1,000,000 | 0 to 200 |

| Model E | Plastic | 150 | 10 | 800,000 | -30 to 70 |

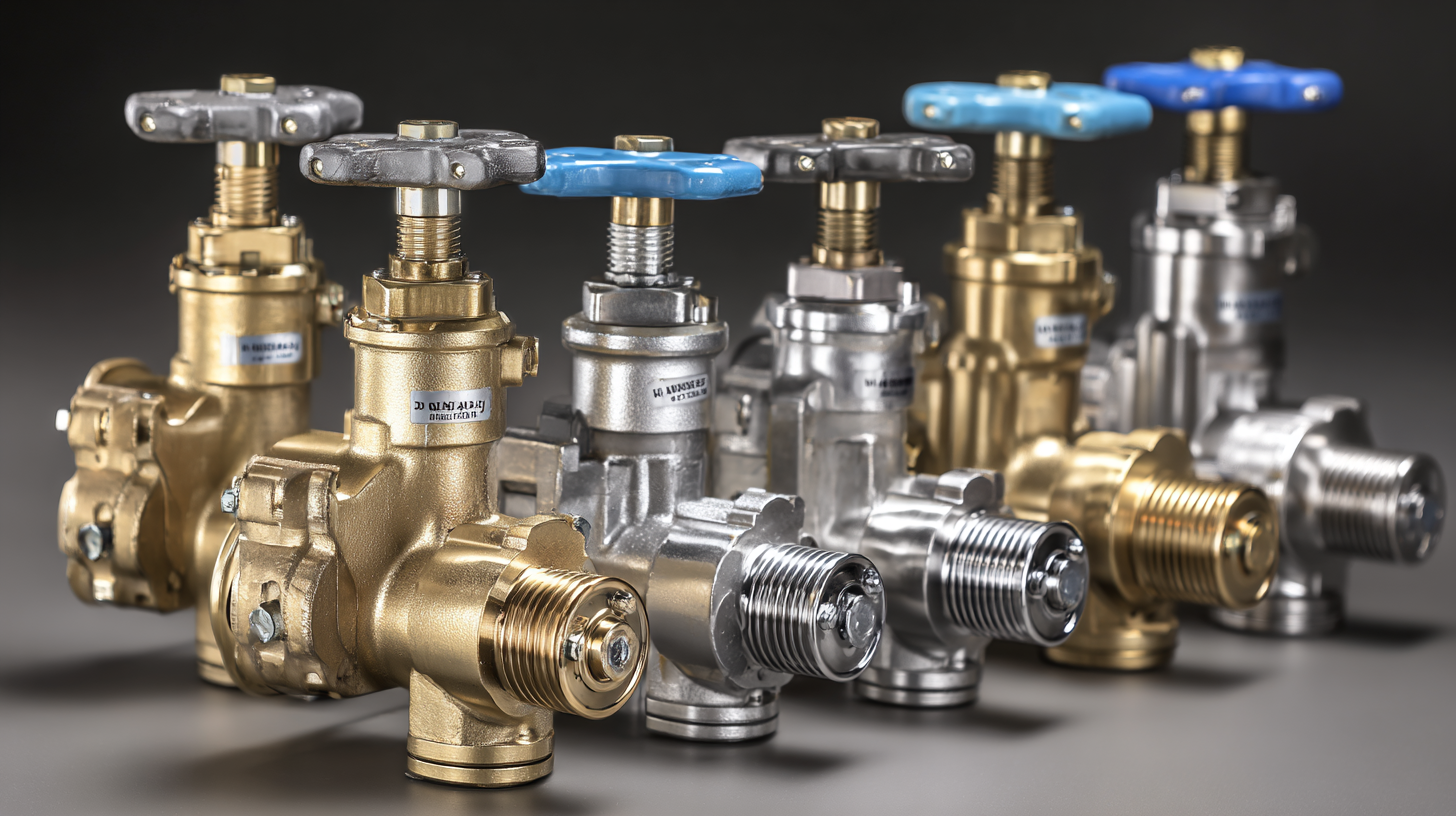

When selecting the right DIN gate valve for your application, understanding the specific requirements of your industry is crucial. According to a recent report by MarketsandMarkets, the global valve market is expected to grow from $75 billion in 2021 to over $100 billion by 2026, highlighting the increasing demand for high-quality valves in sectors such as oil and gas, water supply, and chemical processing. In this competitive landscape, choosing a DIN gate valve that meets rigorous performance standards can significantly impact operational efficiency and safety.

One key factor to consider is the material of the valve. Stainless steel remains a popular choice due to its excellent corrosion resistance and durability, with a growing trend towards duplex stainless steels for higher strength applications. The European Valve Standards (EN 12266) emphasize the importance of testing and certification, ensuring that valves can withstand extreme conditions. Furthermore, consulting performance data and valve test reports can provide insights into the operational reliability you can expect from different manufacturers, allowing you to make well-informed decisions tailored to your unique application needs.

As we look towards 2025, the landscape of DIN gate valve technology is set to undergo significant advancements, driven by the increasing demand for efficiency and sustainability in various industries. According to a recent market analysis by MarketsandMarkets, the global gate valve market is projected to grow from $5.6 billion in 2022 to $7.1 billion by 2025, indicating a compound annual growth rate (CAGR) of approximately 5.5%. This growth reflects an industry-wide shift towards valves that not only comply with rigorous standards but also enhance operational efficiencies.

One notable trend is the integration of smart technology with DIN gate valves. The use of IoT-enabled sensors allows for real-time monitoring of valve performance, contributing to predictive maintenance strategies. This makes it easier to identify potential failures before they occur, ultimately reducing downtime and operational costs. Additionally, manufacturers are adopting advanced materials and coatings to improve corrosion resistance and longevity, a crucial factor in harsh industrial environments.

**Tips:** When selecting DIN gate valves, consider models with smart technology features to enhance process visibility. Regular maintenance schedules can further optimize performance, ensuring your systems run smoothly over the years. As the sector continues to evolve, staying informed about the latest materials and technologies will empower you to make better purchasing decisions.