+86 19720579616

+86 19720579616

Zalo

Zalo

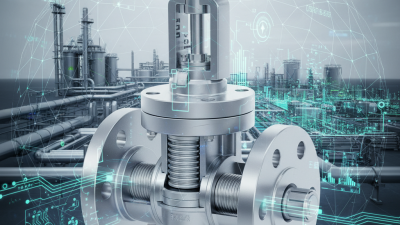

In the world of industrial valves, Din Bellows Sealed Globe Valves stand out for their unique features and benefits. Industry expert, Dr. Emily Carter, once stated, "The integrity and reliability of Din bellows sealed globe valves are unmatched." This highlights their crucial role in various applications.

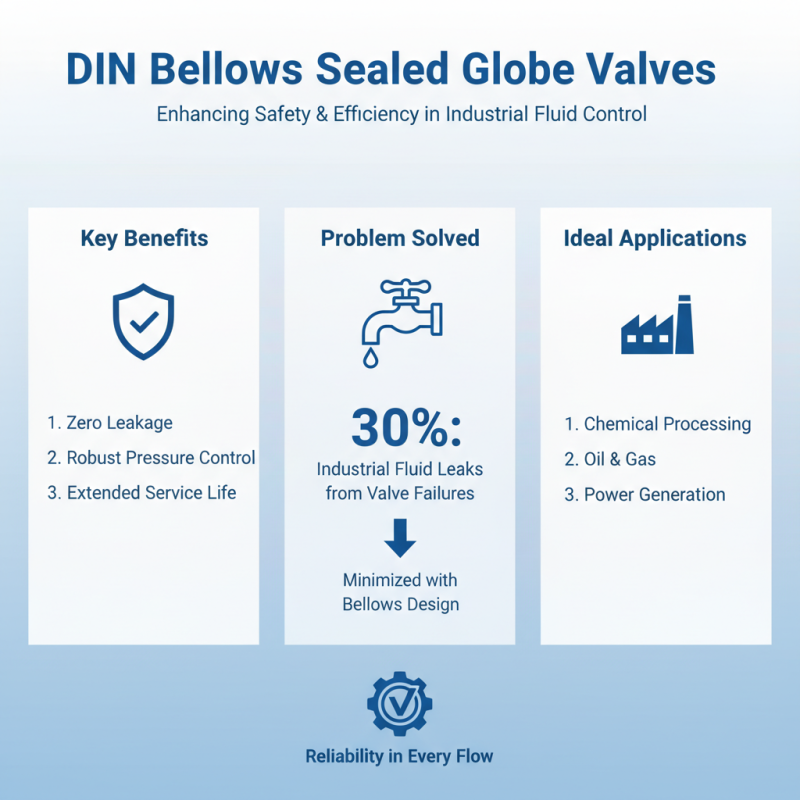

Din Bellows Sealed Globe Valves provide excellent sealing capabilities. They reduce leakage, which is vital for safety and performance. Their design is particularly effective in high-pressure environments. Users have reported a significant decrease in maintenance costs. However, the initial investment can be high.

Moreover, these valves enhance system efficiency. Their operational reliability translates to lower downtime. Some users, though, have expressed concerns about their complexity. Proper training is needed for effective use. Overall, the advantages outweigh the issues when used correctly.

Din bellows sealed globe valves play a crucial role in various industries. They function primarily as control valves, regulating fluid flow. The bellows design provides a robust seal, minimizing the risk of leakage. This feature is particularly vital in applications where maintaining purity or preventing contamination is necessary. The construction allows for tight sealing, contributing to the overall safety and reliability of the system.

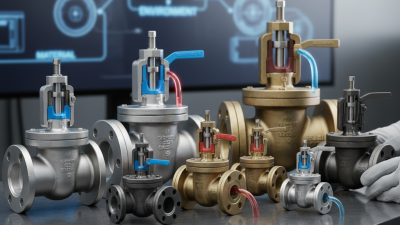

These valves are often used in high-pressure and high-temperature settings. Their resilience against harsh conditions makes them popular in chemical and pharmaceutical industries. However, potential drawbacks exist. For example, improper installation can lead to performance issues. Additionally, routine maintenance is essential to ensure longevity and effective operation. Users must be proactive in their approach to maintenance to avoid unexpected failures. Awareness of these factors can lead to more informed decisions, ensuring better system performance.

Din bellows sealed globe valves offer numerous advantages across various industries. These valves are designed to prevent leakage, safeguarding both the environment and workplace safety. According to a recent report from a leading industrial research firm, improper sealing can lead to losses exceeding $1 million annually in chemical plants due to leaks.

Using bellows sealed globe valves ensures better control of flow, which is critical in operations like oil and gas processing. This precision contributes to energy efficiency and reduces operational costs. The bellows design also minimizes the risk of contamination, essential for industries like pharmaceuticals, where even minor impurities can cause significant issues.

Tip: Regular maintenance checks are vital to extend the lifespan of these valves. Even minor wear can lead to performance loss. Keep an eye on the bellows for any signs of wear or damage.

In demanding environments, the durability of bellows sealed globe valves is crucial. However, they can be susceptible to fatigue over time. It's essential for engineers to consider this when selecting valves for high-cycle applications. Always assess the specific operational conditions to choose the best valve type.

Din bellows sealed globe valves are designed to prevent leaks effectively. This innovative design features a flexible bellows that separates the valve stem from the media. The unique construction minimizes the risk of leakage to a great extent. In high-pressure applications, these valves maintain integrity over time.

The materials used in bellows sealed valves enhance their durability. Despite their advantages, installation can be tricky. Improper fitting may lead to issues down the line. It’s essential to consider the environment where they will be used. Corrosive substances can impact performance. Regular maintenance and inspections are necessary to ensure longevity.

Besides leak prevention, these valves offer excellent flow control. The compact design allows them to fit in tight spaces easily. However, users occasionally overlook the potential complexity they introduce. Understanding the mechanics is crucial for effective operation. Operators must be trained properly to harness their full potential.

Din bellows sealed globe valves are widely used in various industrial systems. They excel in managing fluid flow and pressure control. These valves prevent leakage, making them ideal for applications where safety is crucial. According to industry reports, about 30% of fluid leaks in processes result from valve failures. Therefore, using bellows sealed designs can significantly minimize these risks.

In chemical processing systems, these valves offer outstanding performance. They ensure tight sealing, which is critical when handling aggressive chemicals. A recent study indicated that improper sealing led to an estimated $1 billion in losses annually across the industry. This highlights the importance of reliable valve solutions. Furthermore, their use in HVAC systems helps maintain efficiency. By minimizing thermal energy loss, companies can achieve energy savings of up to 20%.

Despite their benefits, some challenges exist. Installation can be complex and requires skilled technicians. The initial costs may also deter some users. However, the long-term savings from reduced leaks and maintenance often outweigh these concerns. Using data-driven approaches can help assess the overall impact of implementing bellows sealed globe valves in different facilities. Achieving optimal performance demands continuous evaluation and improvement of these systems.

When comparing with other valve types, key differences emerge. DIN bellows valves provide superior sealing, thanks to their unique bellows design. This design minimizes leakage risks, especially in critical applications. In contrast, traditional globe valves with packing can wear over time, leading to leaks. Research indicates that bellows sealed valves can reduce leakage rates by up to 95%. This is crucial for industries handling hazardous fluids.

Another distinction lies in maintenance. DIN bellows sealed globe valves generally require less frequent maintenance compared to their counterparts. This is partly due to their robust construction. A study by industry experts highlights that users can save up to 30% on maintenance costs with bellows valves. However, the initial installation cost may be higher. Some users may hesitate to invest upfront, weighing the long-term savings against initial expenses.

The flow efficiency also varies. Bellows sealed valves can have a better flow coefficient than standard globe valves. This can result in improved system performance, especially in high-pressure scenarios. However, there are still considerations. Not every process requires the advantages that bellows provide. In some cases, simpler valve types might suffice or even outperform in cost-effectiveness.