+86 19720579616

+86 19720579616

Zalo

Zalo

In the world of industrial applications, the importance of reliable and durable components cannot be overstated. Among these critical components, API 602 forged steel valves stand out due to their exceptional strength, versatility, and ability to withstand high pressure and temperature conditions. As industry expert Dr. John Smith, a renowned engineer in valve technology, once stated, "The reliability of API 602 forged steel valves is paramount for ensuring safety and efficiency across various industrial processes." This sentiment highlights the necessity for professionals in multiple fields to understand the significance of these valves.

As industries ranging from oil and gas to water treatment continue to expand, the demand for quality components like API 602 forged steel valves grows. These valves are designed to provide optimal performance and longevity, making them suitable for critical applications where failure is not an option. This article will explore the top 10 API 602 forged steel valves that cater to diverse industry needs, providing insights into their features and benefits. Understanding these offerings not only aids in making informed purchasing decisions but also emphasizes the vital role these valves play in maintaining operational integrity within various sectors.

API 602 forged steel valves are indispensable components in various industrial applications due to their robustness and versatility. These valves are manufactured using high-quality forged steel, which grants them superior strength and durability compared to cast alternatives. One of the defining characteristics of API 602 forged steel valves is their ability to withstand high pressures and temperatures, making them ideal for high-stakes environments such as oil and gas, chemical processing, and power generation. The forged construction also ensures a tighter grain structure, resulting in enhanced corrosion resistance and longevity in service.

Another key characteristic is their compact design, which allows for easier installation in confined spaces while maintaining high performance. API 602 valves are also equipped with precise sealing mechanisms that minimize the risk of leaks and ensure reliable operation. The simplicity of their design further aids in maintenance and repairs, reducing downtime in industrial settings. Additionally, these valves often feature a range of configurations, including globe, gate, and check valve types, catering to diverse fluid control needs across multiple sectors. Overall, the combination of strength, reliability, and adaptability makes API 602 forged steel valves a cornerstone in mechanical systems across various industries.

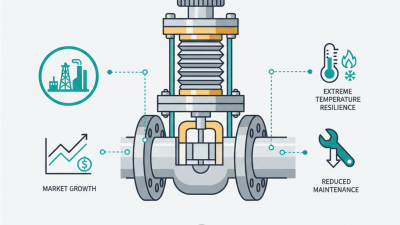

API 602 forged steel valves play a crucial role in various industries due to their robustness, reliability, and ability to withstand high pressures and temperatures. In the oil and gas sector, these valves are essential for controlling the flow of fluids under extreme conditions. Companies in this industry prioritize durability and leak-proof performance because even minor failures can lead to significant safety hazards and operational disruptions. The stringent requirements of API standards ensure that these valves meet industry regulations, providing peace of mind for project managers.

In the power generation industry, API 602 forged steel valves are equally vital. They are used in steam, water, and gas systems, where efficient flow control is necessary for optimal energy production. The requirements here include resistance to corrosion and wear, as well as the ability to operate reliably in high-temperature environments. Utilities require valves that not only adhere to rigorous standards but also offer longevity to minimize maintenance costs and downtime. The compatibility with various fluids and gases ensures that these valves can be tailored to specific system needs across different power plants.

Chemical processing is another key area where API 602 forged steel valves are employed. The industry demands valves that can handle corrosive materials while providing tight shut-off capabilities. Safety is paramount here, with strict adherence to safety standards to prevent leaks and spills that could have catastrophic consequences. As the processing of chemicals often involves aggressive environments, the materials and design of these valves are critical to maintaining system integrity and safety. Ultimately, the versatility and strength of API 602 forged steel valves make them indispensable across multiple sectors, laying the foundation for secure and efficient operations.

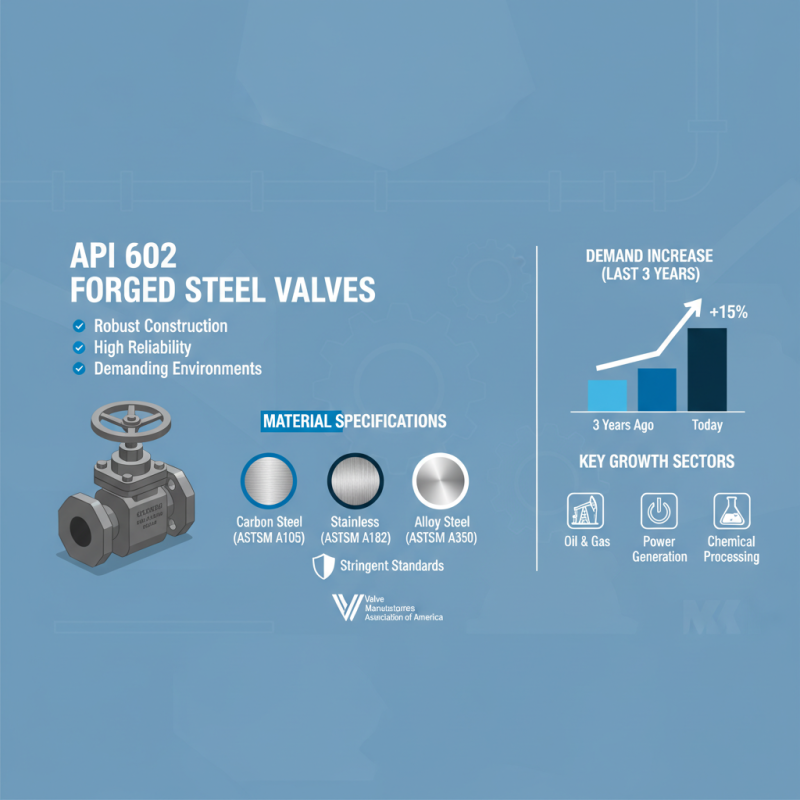

The API 602 forged steel valves are known for their robust construction and high reliability in various industrial applications. The material specifications for these valves are critical, as they must meet stringent standards to ensure performance in demanding environments. Typically, these valves are made from high-quality carbon steel, stainless steel, or alloy steels, which comply with rigorous industry specifications such as ASTM A105, ASTM A182, and ASTM A350. According to a recent industry report by the Valve Manufacturers Association of America, the demand for high-performance valves, including API 602 products, has increased by 15% over the past three years, driven by the growth in sectors like oil and gas, power generation, and chemical processing.

The standards governing API 602 forged steel valves specify not only the material properties but also the testing and quality assurance processes required for production. Valves must undergo pressure testing procedures, including shell and seat tests, to verify their integrity under operational conditions. The American Petroleum Institute stipulates that these valves may be subjected to rigorous assessments to meet API Q1 and ISO 9001 certifications. An analysis by Global Market Insights indicates that adherence to these standards not only enhances safety but also extends the lifespan of valves in critical applications, reducing costs associated with maintenance and failures. Leveraging standardized materials ensures that manufacturers can produce valves that perform consistently across different industries and operational scenarios.

In the competitive landscape of API 602 forged steel valves, it is crucial to understand the strengths and weaknesses of various leading brands. Each manufacturer tends to have unique product features, materials, and design philosophies that cater to different industry requirements. A comparative analysis reveals that while some brands emphasize corrosion resistance and durability, others focus on optimizing flow characteristics or enhancing the ease of maintenance. This diversity provides options for industries ranging from oil and gas to water treatment, where specific applications dictate the most suitable valve choice.

Moreover, factors such as pressure ratings, temperature ranges, and valve sizes play a significant role in performance evaluations among top brands. Some manufacturers utilize advanced technologies for valve sealing and actuation, resulting in minimal leakage and improved reliability under extreme conditions. This analysis helps stakeholders select valves that not only meet regulatory standards but also align closely with operational efficiency goals. By examining the various attributes of these leading players, industries can make informed decisions that enhance their overall productivity and equipment longevity.

Maintaining API 602 forged steel valves is essential for ensuring optimal performance across various industries. These valves are designed to endure high temperatures and pressures, but regular maintenance is required to prevent wear and tear. One of the best practices is to establish a routine inspection schedule. This involves checking for leaks, wear on seals, and overall functionality. Proper lubrication is also crucial; it minimizes friction between moving parts and helps maintain the integrity of the valve's operation over time.

Tips: Always ensure that you replace worn-out parts with high-quality replacements that meet API standards. Regularly calibrate your valves to ensure they are operating within specified parameters, which will also prolong their lifespan.

In addition to routine inspections, it is vital to conduct thorough cleaning of the valves. Accumulation of dirt and debris can lead to blockages, affecting the flow and performance. Using appropriate cleaning agents that are compatible with steel will help in maintaining the valves without causing damage. Furthermore, employee training on proper handling and operational protocols can significantly reduce the risk of valve malfunctions, ensuring a safe and efficient working environment.

Tips: Document all maintenance activities to track performance trends and preemptively address any issues. A comprehensive maintenance log can aid in identifying potential problems before they escalate.

| Valve Type | Size (inches) | Pressure Rating (psi) | Material | Application |

|---|---|---|---|---|

| Gate Valve | 2 | 1500 | A105 | Oil & Gas |

| Globe Valve | 1.5 | 600 | A105 | Chemical Processing |

| Ball Valve | 3 | 1500 | A182 F316 | Water Treatment |

| Check Valve | 4 | 3000 | A105 | Power Generation |

| Filter Valve | 2.5 | 1500 | A516 Gr. 70 | Pharmaceutical |

| Butterfly Valve | 6 | 150 | A216 WCB | HVAC |

| Pinch Valve | 3 | 600 | Rubber Lined | Mining |

| Pressure Relief Valve | 2 | 3000 | A182 F304 | Oil & Gas |

| Solenoid Valve | 1 | 150 | Brass | Automation |

| Swing Check Valve | 4 | 1500 | A105 | Waterworks |