+86 19720579616

+86 19720579616

Zalo

Zalo

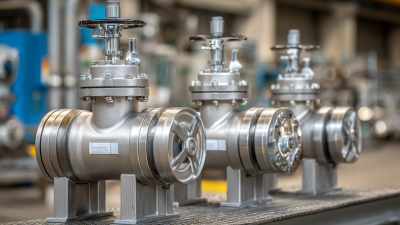

In today's industrial landscape, the importance of selecting the right components for optimal performance cannot be overstated, and this is particularly true for Forged Steel Ball Valves. According to a report by MarketsandMarkets, the global ball valve market is projected to reach USD 18.4 billion by 2025, driven by advancements in manufacturing technology and increasing demand across various sectors, including oil and gas, water treatment, and power generation. The durability, reliability, and superior sealing capabilities inherent to Forged Steel Ball Valves position them as a critical choice for engineers and procurement professionals seeking to enhance the efficiency and safety of fluid control systems. This blog will explore the top strategies for selecting Forged Steel Ball Valves, ensuring optimal performance and longevity in challenging environments.

Forged steel ball valves are essential components in various industries, providing reliable control over fluid flow. Understanding the basics of these valves is crucial for selecting the right ones to ensure optimal performance. Forged steel, known for its strength and durability, is particularly beneficial in high-pressure and high-temperature applications. The manufacturing process involves shaping steel at high temperatures, resulting in a grain structure that enhances the valve's resistance to wear and corrosion.

When considering forged steel ball valves, it’s important to assess the valve's design and its compatibility with the intended application. Factors such as size, pressure rating, and connectivity greatly influence performance. A well-chosen valve can lead to increased efficiency and reduced operational costs. Additionally, regular maintenance and inspection can ensure the longevity and reliability of these valves, mirroring the engineering excellence found in high-performance automotive innovations. Just as enthusiasts seek advanced features and performance from vehicles, choosing the right forged steel ball valve is essential for achieving superior operational results in industrial systems.

When selecting forged steel ball valves, several key factors significantly influence their performance and longevity. One critical aspect is material selection; forged steel offers superior strength and durability compared to cast steel, making it suitable for high-pressure applications. According to a report from the Valves and Actuators Global Market Report 2021, the demand for valve solutions made from high-performance materials is growing, particularly in industries such as oil and gas, where extreme conditions are commonplace.

Another important consideration is the valve size and design specifications. Proper sizing is essential to ensure maximum efficiency and minimize leakage. The American Petroleum Institute (API) states that mismatched valve sizes can lead to increased maintenance costs and operational inefficiencies. Additionally, the design should accommodate the specific flow requirements of the application to prevent cavitation and other performance issues. With the valve market expected to reach $96.2 billion by 2025 (as reported by Research and Markets), making informed decisions on these factors is crucial for achieving optimal valve performance.

When it comes to selecting forged steel ball valves, understanding the different types available is crucial for professionals seeking optimal performance. Forged steel ball valves are typically categorized into three main types: floating, trunnion-mounted, and regular port. According to a market analysis by Transparency Market Research, the global demand for forged steel valves is projected to reach $11.7 billion by 2026, driven by their lightweight, durability, and excellent sealing properties.

Floating ball valves are ideal for low-pressure applications as the ball floats within the valve body, sealing against the downstream seat under pressure. Conversely, trunnion-mounted ball valves are better suited for high-pressure and high-temperature environments, as they feature a fixed ball design that provides greater stability. A report by MarketsandMarkets indicates that the trunnion-mounted segment is expected to grow at a Compound Annual Growth Rate (CAGR) of 5.2% through 2025, driven by increased usage in oil and gas, and chemical processing industries.

Regular port valves, characterized by their compact design, offer a straightforward option for many applications, but may limit flow rates compared to their full-port counterparts. The choice of ball valve significantly affects system efficiency and performance; therefore, professionals must consider factors such as operating pressure, temperature, and fluid characteristics when making their selection. Adopting a strategic approach to valve selection not only enhances system reliability but also contributes to overall operational efficiency.

Maintaining forged steel ball valves is essential for ensuring their optimal performance and longevity. Regular inspections should be conducted to check for any signs of wear and tear, such as leaks or corrosion. Lubrication of the valve stems and seats is also crucial to minimize friction and prevent sticking, which can impair functionality. Using the appropriate lubricant designed for high temperatures and pressures is key to prolonging the life of these valves.

In addition to routine inspection and lubrication, proper cleaning should not be overlooked. Deposits of dirt or debris can lead to operational issues, so valves should be cleaned periodically based on their environment and usage conditions. Implementing a preventive maintenance schedule that includes these practices can significantly enhance the lifespan of forged steel ball valves, ensuring they perform reliably in demanding applications. By taking these maintenance tips to heart, operators can reduce downtime and increase overall system efficiency.

| Criteria | Recommendation | Maintenance Tips |

|---|---|---|

| Material Quality | Choose high-grade forged steel for durability | Perform regular visual inspections for corrosion |

| Valve Size | Select size based on flow requirements | Ensure size matches piping to prevent leakage |

| Pressure Rating | Verify valve can handle system pressure | Regularly test pressure limits in operation |

| End Connection Type | Match with existing pipe connections | Inspect connection integrity periodically |

| Operating Temperature | Ensure valve is rated for the intended temperature | Monitor temperature during maintenance checks |

When choosing forged steel ball valves, many professionals make critical mistakes that can compromise system performance. One common error is neglecting the importance of valve size and pressure rating. According to a report by the American Society of Mechanical Engineers (ASME), improper sizing can lead to flow restrictions, leading to increased energy costs and diminished system efficiency. It's essential to match the valve size to the pipe diameter and ensure it’s rated for the specific pressure and temperature of the application to prevent failure and costly downtime.

Another mistake is overlooking the material compatibility. Forged steel valves are available in various alloys, and not all are suited for every application. For instance, a study conducted by the International Journal of Pressure Vessels and Piping highlighted that using a valve made from the wrong alloy could lead to corrosion and reduced service life, particularly in harsh environments. Selecting the appropriate material ensures enhanced durability and reliability, ultimately safeguarding your investment and maintaining operational integrity. By focusing on these key aspects, professionals can avoid pitfalls that impact both performance and safety.