+86 19720579616

+86 19720579616

Zalo

Zalo

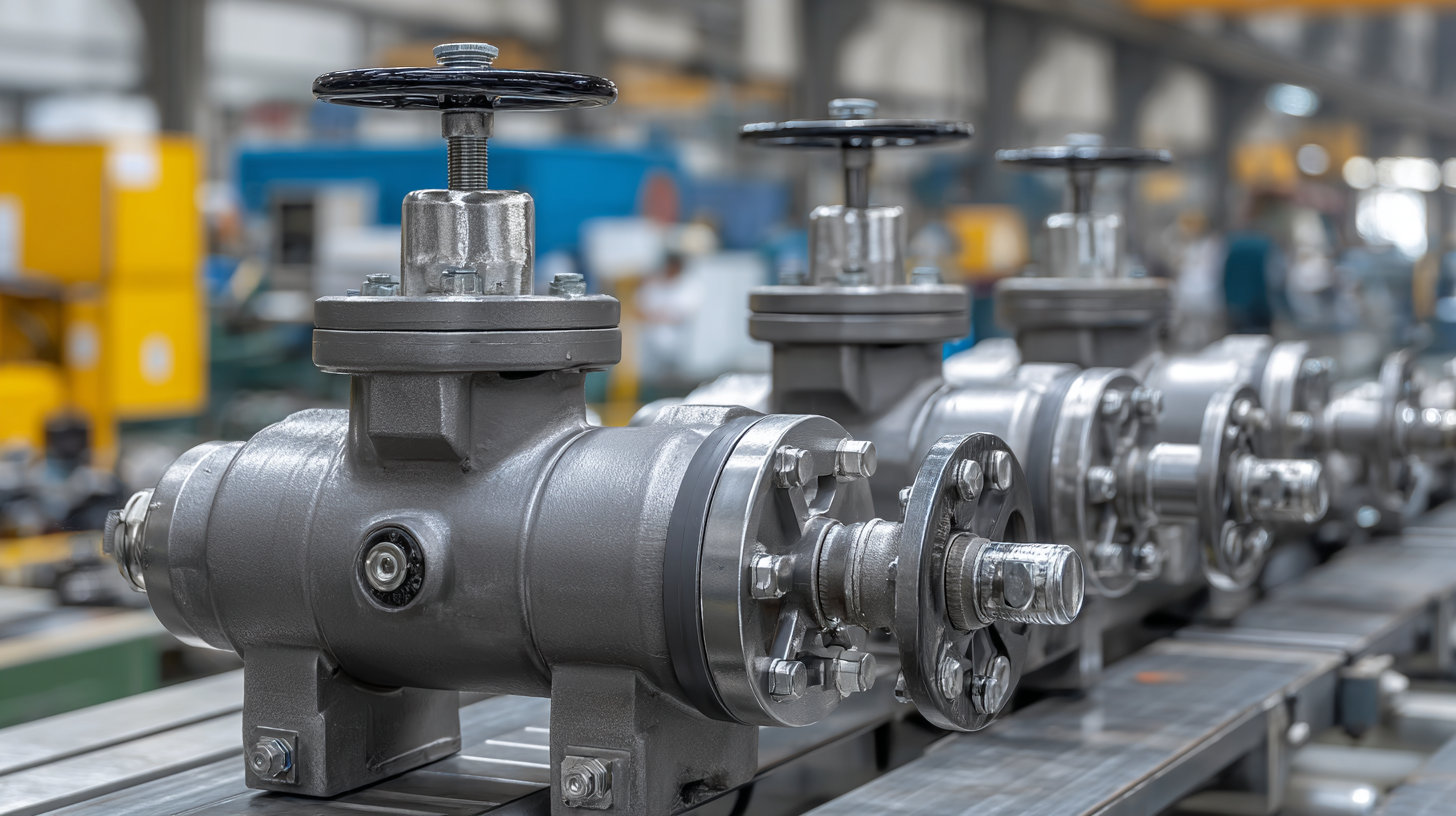

In the pursuit of industrial efficiency, the choice of valves can significantly impact operational performance and reliability. Forged Steel Globe Valves, renowned for their durability and strength, play a critical role in various sectors, including oil and gas, water treatment, and power generation. According to a report by MarketsandMarkets, the global valve market is projected to reach $93.23 billion by 2026, with a notable emphasis on forged steel components due to their superior resistance to high pressure and temperature conditions. As industries strive to enhance their processes while minimizing downtime and energy consumption, understanding the key reasons behind the essentiality of Forged Steel Globe Valves becomes imperative. This blog will explore five pivotal benefits that these valves provide, showcasing their indispensable role in optimizing industrial operations.

Forged steel globe valves play a pivotal role in enhancing the efficiency of industrial systems. These valves are designed to provide excellent flow control and leak-tight sealing, making them ideal for a wide range of applications, from power plants to chemical processing facilities. The structure of forged steel ensures exceptional strength and durability, allowing these valves to withstand high pressures and extreme temperatures, which are common in industrial environments.

Moreover, the reliability of forged steel globe valves significantly reduces maintenance needs and downtime in operations. Their robust construction minimizes the risk of failures, ensuring that systems run smoothly without interruptions. This reliability is essential for improving the overall productivity of industrial processes, as even minor delays can lead to increased costs and lost revenue. By understanding the critical function of these valves, industries can optimize their systems further and achieve greater efficiency in production and operations.

When evaluating the efficiency of industrial systems, the choice of valve plays a crucial role.

Forged steel globe valves stand out for several reasons compared to other valve types, such as gate or ball valves.

One of the most significant advantages of globe valves is their ability to provide precise flow control.

The design of globe valves allows for a more controlled flow rate and pressure drop, making them ideal for applications where maintaining specific flow characteristics is critical.

In contrast, gate valves are typically used for on/off applications and can lead to turbulent flow, while ball valves, although excellent for quick operation, may not provide the same level of control.

When evaluating the efficiency of industrial systems, the choice of valve plays a crucial role.

Forged steel globe valves stand out for several reasons compared to other valve types, such as gate or ball valves.

One of the most significant advantages of globe valves is their ability to provide precise flow control.

The design of globe valves allows for a more controlled flow rate and pressure drop, making them ideal for applications where maintaining specific flow characteristics is critical.

In contrast, gate valves are typically used for on/off applications and can lead to turbulent flow, while ball valves, although excellent for quick operation, may not provide the same level of control.

Additionally, forged steel globe valves are known for their durability and ability to withstand high pressures and temperatures.

This robustness is particularly advantageous in demanding industrial environments, where other valve types may degrade over time or fail under stress.

Furthermore, their compact design allows for easy integration into various systems without requiring significant modifications.

When efficiency is paramount, and reliability is essential, the qualities of forged steel globe valves make them a superior choice in comparison to their counterparts.

Forged steel globe valves have become indispensable in high-pressure applications across various industries, including oil and gas, petrochemical, and power generation. The high tensile strength of forged steel enables these valves to withstand extreme pressures and temperatures, making them ideal for critical processes. According to a report from the Global Valve Industry, the demand for forged steel valves is projected to grow by 6.8% annually, reflecting their crucial role in enhancing operational efficiency and safety in demanding environments.

One of the primary advantages of using forged steel globe valves is their superior sealing capability. The precision engineering of these valves allows for minimal leakage, which is vital in high-pressure systems where even the slightest leak can lead to catastrophic failures. A study by the American Society of Mechanical Engineers (ASME) indicates that properly functioning globe valves can reduce the risk of accidents by up to 30%, underscoring their importance in maintaining optimal safety standards. Additionally, their robust design ensures a longer service life, reducing downtime and maintenance costs, which are crucial factors in maximizing industrial productivity.

Forged steel globe valves play a crucial role in enhancing process control and stability in various industrial applications. Their robust construction allows them to withstand high pressures and temperatures, making them ideal for demanding environments. This durability not only ensures a longer lifespan but also minimizes downtime due to maintenance or replacement, allowing industries to operate smoothly and efficiently.

Moreover, the design of forged steel globe valves promotes precise flow regulation. Their ability to provide tight sealing and excellent throttling capabilities enables operators to control the flow of fluids with remarkable accuracy. This level of control is essential for maintaining optimal conditions in processes where even slight fluctuations can lead to inefficiencies or safety hazards. By utilizing forged steel globe valves, industries can safeguard their operations while achieving superior performance and stability in their systems.

| Reason | Description | Impact on Efficiency | Ideal Applications |

|---|---|---|---|

| 1. High Durability | Forged steel valves are designed to withstand high pressure and temperature. | Reduces downtime due to valve failures. | Oil & Gas, Power Generation |

| 2. Superior Flow Control | Provides precise control over the flow rates of fluids. | Enhances overall process stability and efficiency. | Chemical Processing, Water Treatment |

| 3. Easy Maintenance | Forged steel valves have simple designs for quick maintenance. | Minimizes maintenance costs and time. | Manufacturing, Pharmaceuticals |

| 4. Resistance to Corrosion | Forged steel can be treated for corrosion resistance, extending valve life. | Reduces replacement frequency and associated costs. | Marine Applications, Wastewater Management |

| 5. Versatile Design | Available in various sizes and configurations for diverse applications. | Promotes flexibility in system design and integration. | Food Processing, HVAC Systems |

When it comes to maintaining the efficiency of forged steel globe valves in industrial settings, proactive maintenance practices are crucial. Regular inspection is a fundamental aspect, allowing operators to identify any wear or potential failures before they escalate. Checking for leaks, unusual noise, or vibrations can provide early warning signs that maintenance is needed. Additionally, maintaining the proper lubrication of the valve components reduces friction and wear, thus extending their operational lifespan.

Another critical aspect of maintenance is the regular cleaning of globe valves. Accumulation of debris or build-up of corrosion can hinder the valve’s performance, leading to inefficiencies or failures. Implementing a routine cleaning schedule ensures that valves operate smoothly and reliably, contributing to the overall efficiency of industrial processes. Lastly, operators should ensure that adjustments are made in accordance with the manufacturer’s guidelines, which can help to mitigate unnecessary stress on the valves and help maintain their integrity over time. Following these practices not only enhances the longevity of globe valves but also supports broader operational efficiency within industrial applications.

This chart illustrates the importance level of the key features of forged steel globe valves in industrial efficiency. The ratings, ranging from 1 to 10, highlight the critical aspects that contribute to their overall performance and reliability in various industrial applications.