+86 19720579616

+86 19720579616

Zalo

Zalo

In the industrial sector, the choice of valves is crucial for ensuring operational efficiency and safety. According to a recent market report by Mordor Intelligence, the global valve market is projected to reach $89.3 billion by 2025, with forged steel gate valves becoming increasingly favored due to their durability and reliability. Forged Steel Gate Valves provide exceptional performance under high pressure and temperature conditions, making them essential for a variety of applications, including oil and gas, water management, and chemical production. As industries continuously seek to enhance their systems while minimizing downtime and maintenance costs, the adoption of forged steel gate valves stands out as a strategic decision. This blog will delve into the five essential reasons why investing in Forged Steel Gate Valves is a prudent choice for fulfilling your industrial needs.

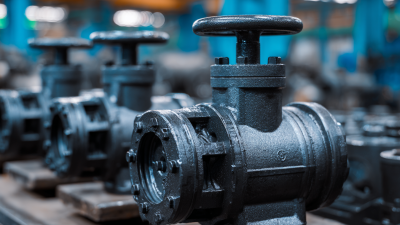

Forged steel gate valves are becoming increasingly popular in various industrial applications, primarily due to their exceptional durability. In demanding environments where pressure and temperature fluctuations are a common occurrence, these valves stand out as a reliable choice. Unlike cast valves, which may be prone to cracking under stress, forged steel offers superior strength and resistance to wear and tear. This is a crucial advantage in industries such as oil and gas, chemical processing, and power generation, where equipment must withstand harsh conditions.

Forged steel gate valves are becoming increasingly popular in various industrial applications, primarily due to their exceptional durability. In demanding environments where pressure and temperature fluctuations are a common occurrence, these valves stand out as a reliable choice. Unlike cast valves, which may be prone to cracking under stress, forged steel offers superior strength and resistance to wear and tear. This is a crucial advantage in industries such as oil and gas, chemical processing, and power generation, where equipment must withstand harsh conditions.

The manufacturing process of forged steel enhances the molecular structure of the material, making the valves less likely to deform or fail under extreme conditions. This resilience translates to better performance and longer service life, reducing the need for frequent replacements or repairs. Additionally, forged steel gate valves can handle higher pressures, making them suitable for high-stakes operations where safety is paramount. By opting for these valves, companies not only ensure operational efficiency but also protect their investments in equipment and infrastructure, reinforcing the overall durability and reliability of their industrial systems.

When considering the long-term operational costs of industrial systems, the choice of gate valves is crucial. Forged steel gate valves stand out for their exceptional durability and reliability, translating to significant cost efficiency over time. Unlike their cast counterparts, forged steel valves can withstand higher pressure and temperature variations, reducing the frequency of replacements or repairs. This longevity directly impacts your maintenance budget, allowing for more predictable operational costs.

Moreover, the sealing capabilities of forged steel gate valves contribute to cost efficiency. Their robust design minimizes the risk of leaks, thereby preventing product loss and the associated costs. Investing in high-quality forged steel gate valves means lower operational interruptions and maintenance downtime, which are critical for industries that rely on continuous production. Ultimately, the initial investment in forged steel gate valves is offset by their reliable performance and lower lifecycle costs, making them a smart choice for any industrial application.

When choosing valves for industrial applications, it’s crucial to consider the material and design. Forged steel gate valves stand out for their durability and reliability, making them a preferred choice over other materials such as cast iron or plastic. Forged steel offers superior strength and resistance to high-pressure and temperature conditions, ensuring consistent performance in demanding environments.

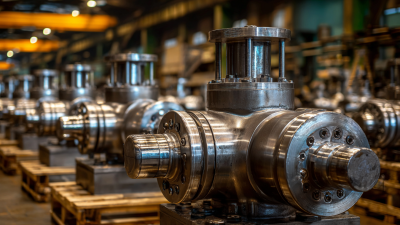

The square stem design of forged steel gate valves offers enhanced stability and ease of installation, setting it apart from conventional round-stem valves. This feature allows for a more secure grip during operation, minimizing the risk of failure under heavy loads. Additionally, since screws are not included, users can easily integrate these valves into existing systems without the hassle of sourcing extra components.

Tips: When selecting a forged steel gate valve, consider the specific pressure and temperature requirements of your application to ensure optimal performance. Regular maintenance and inspection can extend the life of your valves, preventing unexpected downtimes. Lastly, always consult with a professional if unsure about compatibility or installation to ensure safe and efficient operations.

Forged steel gate valves have emerged as a top choice in industrial applications, particularly due to their high-pressure ratings, which significantly impact performance in critical operations. Industry reports, such as those from the Global Valve Market Analysis, indicate that forged steel valves can withstand pressures up to 10,000 psi, making them ideal for demanding environments like oil and gas, power generation, and chemical processing. The superior strength and durability of forged steel create a reliable solution for managing high pressures, thereby ensuring operational safety and reducing the risk of catastrophic failures.

Moreover, the cost-effectiveness of using forged steel gate valves in high-pressure systems cannot be overlooked. According to a recent study by the American Society of Mechanical Engineers (ASME), utilizing valves with higher pressure ratings can lead to decreased maintenance costs and increased system longevity. This is particularly crucial in sectors where downtime can equate to significant financial losses. The lower incidence of leaks and failures in forged steel valves contributes to overall efficiency and aids in compliance with stringent industrial standards, reinforcing their essential role in modern facilities.

Forged steel gate valves are increasingly recognized for their ability to meet stringent industrial safety standards and regulations. These valves are manufactured through a process that enhances their mechanical properties, making them more resilient to high pressures and temperatures. This durability is particularly crucial in industries that handle hazardous materials, as it ensures that the valves can withstand extreme operating conditions without failing. Regulatory bodies often mandate the use of robust materials, and forged steel valves consistently comply, thereby providing peace of mind to operators and safety inspectors alike.

As industries evolve, particularly with the rise of advanced applications such as hydrogen-powered vehicles, the demand for reliable valve systems becomes critical. Predictive modeling, such as long short-term memory (LSTM) algorithms, is being utilized to analyze and forecast the behavior of pressure valves under varying temperature conditions. This trend emphasizes the importance of reliable valve performance to meet evolving safety requirements. In the current climate of rapid technological advancement and regulatory scrutiny, opting for forged steel gate valves not only aligns with industry standards but also enhances overall safety in industrial operations.

| Reason | Description | Compliance | Benefits |

|---|---|---|---|

| Durability | Forged steel valves are designed to withstand high pressures and temperatures. | Meets ANSI B16.34 standards. | Reduces maintenance costs and downtime. |

| Safety | Designed to minimize leakage and prevent accidents. | Complies with OSHA regulations. | Enhances operational safety for workers. |

| Quality Assurance | Strict manufacturing processes ensure consistent quality. | ISO 9001 certification and other quality standards. | Reliability in critical operations. |

| Versatility | Suitable for a wide range of applications. | Compliant with various industry standards. | Adaptable to different industrial environments. |

| Cost-Effectiveness | Lower long-term costs due to durability and reduced failures. | Meets cost-benefit analysis requirements. | Optimizes budget allocation for valve systems. |