+86 19720579616

+86 19720579616

Zalo

Zalo

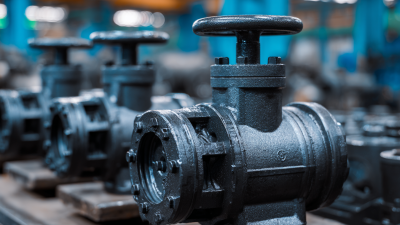

In the world of industrial applications, the choice of valves plays a crucial role in ensuring efficiency and reliability in fluid control systems. One particularly important type is the Bs 5163 Non-Rising Stem Resilient Seated Gate Valves. These valves are designed with a unique construction that offers significant advantages in various operational environments, making them essential for many industries. In this blog, we will explore five compelling reasons why the Bs 5163 Non-Rising Stem Resilient Seated Gate Valves are favored by engineers and plant managers alike. From their durability and low maintenance requirements to their excellent sealing capabilities, understanding these benefits will provide valuable insights into why they are a critical component in modern industrial systems. Whether you're involved in water treatment, oil and gas, or manufacturing, this guide will help you appreciate the pivotal role these valves play in enhancing system performance and reliability.

BS 5163 non-rising stem resilient seated gate valves have become an indispensable component in various industrial applications due to their unique design and operational benefits. These valves allow for improved sealing capabilities while also preventing leakage, which is crucial in settings that require stringent safety measures. According to a report by the International Water Association, approximately 30% of global water loss is attributed to valve leakage, emphasizing the importance of reliable valve technologies like the BS 5163.

The design features of BS 5163 valves make them particularly suitable for environments where space considerations are key. Unlike rising stem gate valves, the non-rising stem design minimizes the vertical space required, allowing for easier installation in confined areas. Furthermore, data from the Valve Manufacturers Association indicates that using non-rising stem valves can lead to a 15% reduction in installation costs, which is a significant advantage in budget-sensitive projects. In addition to cost savings, these valves are manufactured to adhere to rigorous standards, ensuring durability and a longer life span, which ultimately leads to decreased maintenance needs and operational downtime.

In industrial settings, the significance of BS 5163 non-rising stem resilient seated gate valves cannot be overstated. These valves are engineered to provide reliable performance and durability, making them indispensable for various applications. One of the key features is their resilient seating, which offers a superior seal and minimizes leakage, thus enhancing system efficiency. Furthermore, their non-rising stem design reduces the space required for installation, making them ideal for confined environments.

Tip: When selecting gate valves for your industrial operations, ensure they meet the necessary standards for your specific application. Evaluate factors such as pressure ratings, material compatibility, and flow characteristics to optimize performance.

Another advantage of BS 5163 gate valves is their robust construction, which ensures longevity, even in harsh conditions. The materials used in their manufacture are typically resistant to corrosion and wear, promoting a longer service life and reduced maintenance costs. Additionally, their simple operation makes them user-friendly, allowing for quick adjustments and seamless integration into existing systems.

Tip: Regular maintenance checks can significantly extend the lifespan of your gate valves. Implement a routine inspection schedule to identify wear and tear early, ensuring your systems remain operational and efficient.

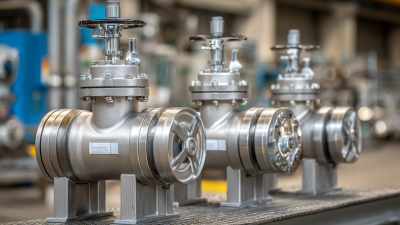

BS 5163 non-rising stem resilient seated gate valves play a crucial role in numerous industrial applications, owing to their robust design and reliable performance. These valves are particularly beneficial in water supply systems, wastewater treatment facilities, and various chemical processing industries. Their resilient seat design ensures a tight seal, preventing leaks and minimizing the loss of valuable resources. This feature is essential in maintaining efficient operations and compliance with environmental regulations.

In addition to water and wastewater management, BS 5163 valves are widely used in heating and cooling systems, oil and gas pipelines, and HVAC applications. Their ability to handle high pressure and temperature variations makes them suitable for challenging environments. Furthermore, the non-rising stem design allows for easy installation in areas with limited vertical space, making these valves versatile for various installation scenarios. By integrating BS 5163 valves into industrial processes, facilities can enhance operational efficiency while ensuring safety and reliability in fluid control systems.

When evaluating various gate valves for industrial applications, BS 5163 non-rising stem resilient seated gate valves stand out for their unique features and superior performance compared to other types. Unlike traditional rising stem gate valves, the non-rising design offers substantial space-saving benefits in installations with limited overhead clearance. This compact nature does not compromise the valve's functionality, ensuring reliable operation and ease of maintenance, two critical requirements in industrial settings.

Additionally, resilience is a key characteristic that differentiates BS 5163 valves from their counterparts. Their enhanced sealing capabilities facilitate effective management of fluid flow while preventing leakage, thus contributing to a safer and more efficient system. In contrast, other gate valve types may not provide the same level of durability or have higher susceptibility to wear and tear, especially in demanding environments. The use of resilient seating materials further enhances their lifespan, making BS 5163 valves an economically advantageous choice over time.

Proper maintenance of BS 5163 non-rising stem resilient seated gate valves is crucial for extending their lifespan and ensuring optimal performance in industrial applications. According to industry reports, regular inspections and timely servicing can enhance the longevity of these valves by up to 30%. Implementing a well-planned maintenance schedule not only prevents unexpected failures but also reduces operational downtime, which is pivotal for maintaining productivity.

**Tips for Maintaining BS 5163 Valves:**

1. **Routine Inspections:** Schedule regular check-ups to identify wear and tear early. Frequent assessments can help in detecting issues like corrosion or leakage before they escalate.

2. **Proper Lubrication:** Use suitable lubricants for the valve stem and threads to minimize friction and prevent sticking, which can compromise their functionality.

3. **Environmental Considerations:** Ensure that the valves are installed in environments that protect against harsh chemicals or extreme temperatures, as these conditions can dramatically reduce their lifespan.

By following these best practices, industries can significantly mitigate maintenance costs and enhance the reliability of their valve systems.