+86 19720579616

+86 19720579616

Zalo

Zalo

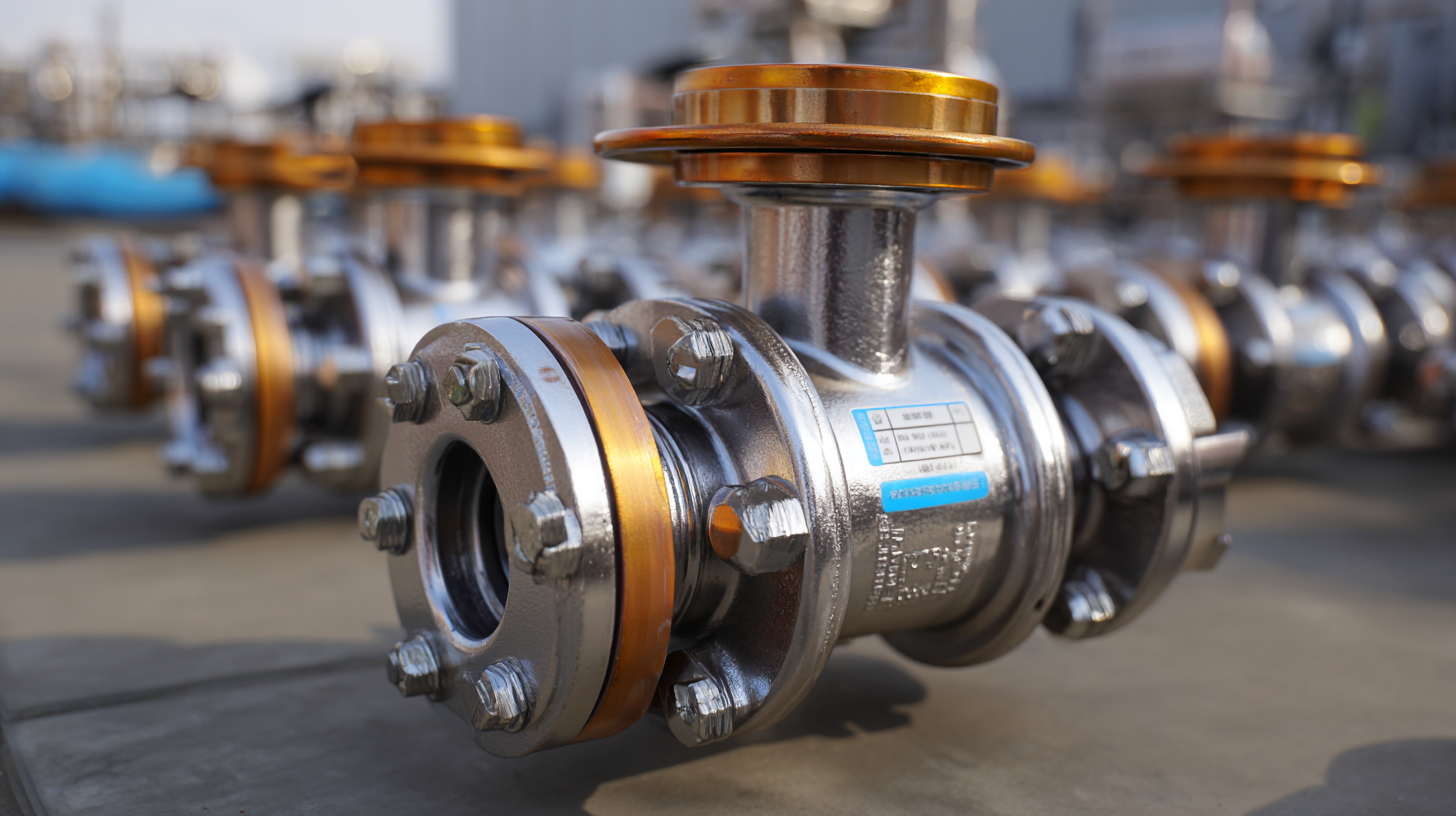

As we approach 2025, the technology landscape is rapidly evolving, with innovations poised to reshape various industries. According to a report by Gartner, the global digital transformation market is projected to reach $2.3 trillion by 2025, highlighting the critical role of advanced technologies. In industrial applications, enhanced equipment reliability and efficiency are paramount, which is where Din Bellows Sealed Globe Valves come into play. These valves are essential for providing leak-free sealing in critical systems, significantly reducing maintenance costs and downtime. The advantages they offer, such as excellent temperature control and resistance to thermal expansion, align perfectly with the growing demand for more sustainable and efficient industrial processes. Embracing these advancements not only enhances operational efficiency but also contributes to the broader push towards smart factories and digitalized workflows.

As we look ahead to 2025, several emerging technology innovations are set to shape various industries. According to a recent Gartner report, technologies such as artificial intelligence (AI), blockchain, and the Internet of Things (IoT) are forecasted to drive significant transformations. The global AI market is expected to reach $190 billion by 2025, emphasizing the growing reliance on machine learning and automation to enhance operational efficiency and decision-making processes across sectors.

In addition to AI, advancements in blockchain technology are predicted to revolutionize supply chain management and cybersecurity. A study by Deloitte suggests that by 2025, over 75% of enterprises will be using blockchain to strengthen transparency and trust. Moreover, the IoT ecosystem is anticipated to grow exponentially, with an estimated 75 billion devices connected by 2025, enhancing data collection and real-time insights.

In industries where precision control is critical, like oil and gas or water treatment, the demand for high-quality valves, such as DIN bellows sealed globe valves, will continue to surge. These valves, designed to prevent leakage and maintain optimal performance under extreme conditions, are essential for maintaining stringent safety and operational standards. Investing in these innovative technologies will not only improve efficiency but also boost sustainability efforts across various sectors, paving the way for a more resilient future.

| Technology Trend | Description | Expected Benefits |

|---|---|---|

| Artificial Intelligence Expansion | Widespread adoption in various industries for improved efficiency. | Enhanced decision-making processes and reduced operational costs. |

| 5G Technology | A global rollout increasing data transfer speeds and connectivity. | Faster internet access leading to enhanced mobile experiences. |

| Sustainable Tech Innovations | Focus on renewable energy solutions and waste reduction technologies. | Lower environmental impact and reduced energy costs. |

| Quantum Computing | Advent of quantum systems solving complex problems faster than classical computers. | Dramatic increases in computational power for industries such as pharma and finance. |

| Internet of Things (IoT) | Increased interconnectivity of devices in homes and industries. | Enhanced automation and efficiency in everyday tasks and operations. |

The globe valve industry is projected to experience significant growth as we approach 2025, reflecting broader trends within the control valve market, which is expected to expand from USD 7.8 billion in 2024 to an impressive USD 15.5 billion by 2032, showcasing a CAGR of 9.1% during the 2025-2032 period. This robust market growth can be attributed to the increasing demand for efficient fluid control across various sectors including oil and gas, water treatment, and industrial processing.

As part of this trend, the globe valve segment particularly stands out, thanks to its critical application in regulating and throttling flow. Industry experts predict that the global butterfly valves market will reach USD 11.7 billion by 2025, growing at a CAGR of 6.5%, further indicating the rising importance of valve technology in modern applications. Additionally, the demand analysis in the cardiac tissue engineering market, projected to be valued at USD 2,943.92 million by 2034, underscores the necessity for advanced fluid control solutions that can ensure precision and reliability in medical applications, further cementing the pivotal role of globe valves in diverse industries.

As part of this trend, the globe valve segment particularly stands out, thanks to its critical application in regulating and throttling flow. Industry experts predict that the global butterfly valves market will reach USD 11.7 billion by 2025, growing at a CAGR of 6.5%, further indicating the rising importance of valve technology in modern applications. Additionally, the demand analysis in the cardiac tissue engineering market, projected to be valued at USD 2,943.92 million by 2034, underscores the necessity for advanced fluid control solutions that can ensure precision and reliability in medical applications, further cementing the pivotal role of globe valves in diverse industries.

In the realm of fluid control, bellows sealed globe valves have emerged as a game-changer, offering significant advantages that enhance safety and efficiency. These valves are designed to effectively prevent leaks, a critical feature for applications where fluid containment is paramount. Unlike traditional valves, the bellows design isolates the stem and internal components from the flowing media, thus mitigating the risk of leakage and minimizing environmental impact. This innovation not only protects surrounding areas from potential contamination but also boosts the operational reliability of fluid systems.

Additionally, the efficiency of bellows sealed globe valves contributes to optimized flow control in various industries. They are particularly advantageous in high-pressure and high-temperature applications, where conventional valve designs may fail or require frequent maintenance. By implementing these advanced valves, manufacturers can achieve better performance and reduce downtime related to repairs. As industries continue to evolve and embrace better safety standards, the adoption of bellows sealed globe valves will likely increase, leading to enhanced operational efficiency and peace of mind in fluid management systems.

The integration of the Internet of Things (IoT) in valve technology is set to revolutionize operations and maintenance by 2025. As industries continue to embrace digital transformation, IoT-enabled valves will provide real-time monitoring and data analytics, enhancing operational efficiency. These smart valves can communicate performance metrics and detect abnormalities, allowing for swift interventions that minimize downtime. By utilizing predictive maintenance strategies powered by IoT, organizations can anticipate failures before they occur, thus improving reliability and reducing repair costs.

Moreover, the advancements in IoT technology introduce significant advantages for globe valves, particularly those featuring bellows seals. These valves, known for their ability to maintain control over variable flow conditions, become even more efficient when integrated with IoT systems. Users can gain insights into valve conditions, enabling optimized performance and extended service life. The marriage of bellows sealed globe valves with IoT also aids in maintaining safety standards by ensuring that leaks can be detected early, thereby protecting both personnel and equipment. As we move towards 2025, the synergy between valve technology and IoT will not only streamline operations but also redefine maintenance protocols in various industries.

This chart represents the projected increase in the integration of IoT technology in valve operations and maintenance from 2023 to 2025. The data shows a trend towards greater efficiency and real-time monitoring capabilities.

As we look towards 2025, the future of valve design is being fundamentally reshaped by advancements in materials and technologies. Innovative materials such as high-performance polymers and composite materials are gaining traction, allowing manufacturers to create valves that are not only more durable but also resistant to extreme temperatures and corrosive environments. This transition from traditional metals to these modern materials enhances efficiency and reliability, making valves suited for demanding applications across various industries.

Furthermore, the integration of smart technology is set to revolutionize valve operation and monitoring. With the rise of Industry 4.0, features such as IoT connectivity and advanced sensors will enable real-time performance tracking and predictive maintenance. This shift will not only reduce downtime but also optimize operational efficiency by allowing facility managers to make informed decisions about valve management. As these trends unfold, companies that adopt best practices in valve design, including bellows sealed globe valves, will find themselves at a competitive advantage, capable of meeting the evolving demands of the market.