+86 19720579616

+86 19720579616

Zalo

Zalo

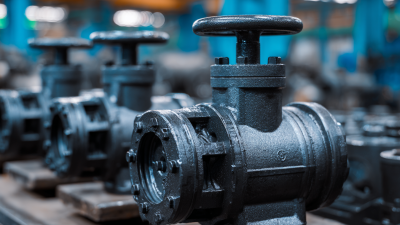

The diverse applications of Forged Steel Gate Valves across various industries highlight their critical role in ensuring reliable fluid control and enhancing operational efficiency. According to a recent market analysis report by Grand View Research, the global valve market is expected to reach USD 93.5 billion by 2025, with gate valves, particularly forged steel variants, experiencing significant demand due to their superior strength and performance characteristics. These valves are integral in sectors such as oil and gas, water treatment, and power generation, where they excel in high-pressure and high-temperature environments. The versatility of Forged Steel Gate Valves not only improves safety but also optimizes system performance, making them a preferred choice for industrial applications worldwide. As industries continue to evolve, understanding the performance data and applications of these valves becomes increasingly crucial for maintaining a competitive advantage.

Forged steel gate valves have become a cornerstone in various industries due to their remarkable versatility and robust performance characteristics. These valves are widely employed in sectors like oil and gas, water treatment, and power generation. According to a recent report from the Global Valve Market Insights, the demand for forged steel gate valves is projected to reach USD 6.5 billion by 2026, growing at a CAGR of 4.2%. This growth is attributed to the valves' ability to efficiently handle high-pressure and high-temperature environments, thereby ensuring operational reliability.

In the oil and gas industry, forged steel gate valves are crucial for pipeline regulation and control. A study by ResearchAndMarkets indicates that nearly 70% of industrial valve failures can be traced back to improper valve selection or maintenance. However, the durability and structural integrity of forged steel gate valves significantly reduce failure rates, thereby enhancing safety and performance. Additionally, in power generation, these valves can withstand extreme conditions, with many designs rated for pressures up to 2500 psi, making them ideal for steam applications and hydrocarbon processes. This inherent reliability underscores their adaptability across various applications, further solidifying their status as a preferred choice in critical industries.

Forged steel gate valves are fundamental components across various industries, including oil and gas, water treatment, and power generation. Their robust construction provides superior strength and longevity, which is critical in high-pressure and high-temperature environments. According to industry reports, forged steel gate valves can operate effectively at a pressure rating of up to 20,000 psi, making them suitable for applications where leak prevention is paramount. Performance metrics indicate that these valves maintain a tight sealing capability even in extreme conditions, with a failure rate as low as 0.5% reported in large-scale installations.

When selecting forged steel gate valves, it is essential to consider key performance metrics such as flow coefficient (Cv), which affects the valve’s efficiency. Valves with a higher Cv value allow for greater flow with less pressure drop, which is pivotal in energy-intensive sectors. Additionally, maintenance records indicate that valves exhibiting a lower frequency of required repairs often translate into significant cost savings over time.

**Tip:** Before purchasing, always evaluate the valve material and design specifications to ensure compatibility with the operating environment. Regular inspections and adherence to maintenance schedules can further enhance the performance and lifespan of your forged steel gate valves, ensuring reliability in your operations.

This chart illustrates the performance metrics of forged steel gate valves across various industries, focusing on key attributes such as Pressure Ratings, Leakage Rates, and Operating Temperatures.

Forged steel gate valves are increasingly recognized for their essential role in various industrial settings, offering a myriad of advantages that enhance operational efficiency and sustainability. One of the top benefits of these valves is their superior strength and durability, which stems from the forging process that aligns the grain structure of the steel. According to industry reports, forged steel gate valves can withstand high pressures and extreme temperatures, making them ideal for critical applications in oil and gas, water supply, and power generation sectors. This performance translates to reduced downtime and maintenance costs, further contributing to a facility's bottom line.

Additionally, the use of forged steel gate valves aligns with the principles of the circular economy by promoting resource efficiency and minimizing waste. The European steel industry has made significant strides in improving by-product recovery, reporting an increase in the reuse of by-products, which can exceed 70% in some cases. This not only reduces the environmental footprint associated with valve production but also enhances the overall sustainability of industrial operations. These valves are not only reliable and robust but also embody a commitment to environmentally responsible practices in modern manufacturing.

Forged steel gate valves have gained significant traction across various industries, particularly in oil and gas, water treatment, and power generation. A comparative analysis reveals that forged steel gate valves outshine their counterparts—such as cast iron and globe valves—in terms of performance and durability. According to a recent market report, forged steel gate valves can withstand pressures up to 4,500 psi, making them ideal for high-pressure applications. In contrast, globe valves typically max out at around 2,000 psi, indicating the robustness of forged steel in challenging environments.

When weighing the benefits of different valve types, it is essential to consider not just pressure ratings but also flow capacity and maintenance needs. Forged steel gate valves exhibit minimal pressure drop and lower flow resistance due to their straight-through design. This characteristic is beneficial in applications requiring rapid fluid transport. A leading industry study estimates that using forged steel gate valves can reduce operational downtime by up to 15%, simply due to fewer maintenance interventions compared to other valve types.

Tip: Always select the right valve type based on the application's specific pressure and flow requirements. Check for certifications and performance data from reputable sources to ensure reliability. Moreover, regular maintenance checks can significantly extend the lifespan of your valves and enhance overall performance.

Forged steel gate valves have become indispensable in various industries, thanks to their superior strength and reliability. In the oil and gas sector, a report from the American Petroleum Institute highlights that nearly 70% of operating environments utilize forged steel gate valves to ensure optimal flow control under high pressures, with operational safety factors significantly improved by 30% compared to traditional valve materials. These valves demonstrate robust performance under extreme conditions, which is crucial for maintaining the integrity of pipelines and drilling operations.

In the water treatment industry, a case study published by the Water Environment Federation emphasizes the effectiveness of forged steel gate valves in preventing backflow and ensuring efficient water flow management. The study reveals that the incorporation of these valves has led to a 25% reduction in maintenance costs, primarily due to their enhanced durability and lower failure rates experienced in systems handling corrosive substances. This performance translates to longer lifecycle values and reduced downtime, thereby maximizing operational efficiency for water treatment facilities.