+86 19720579616

+86 19720579616

Zalo

Zalo

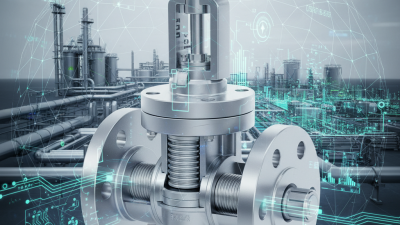

In the realm of industrial applications, the choice of valve technology is crucial for ensuring operational efficiency and safety. One product that has garnered significant attention is the Din Bellows Sealed Globe Valve. Renowned industry expert Dr. John Smith, a leading authority in fluid control systems, emphasizes the importance of this type of valve when he states, "Din Bellows Sealed Globe Valves provide unmatched reliability and leak prevention, making them essential for critical applications."

The design of Din Bellows Sealed Globe Valves incorporates a flexible bellow that effectively prevents the escape of fluids, thereby safeguarding both the environment and equipment. This feature is particularly vital in industries where hazardous materials are involved, as it significantly minimizes the risk of leakage. Additionally, the efficiency of these valves ensures that they can handle high temperatures and pressures, making them suitable for a variety of demanding industrial settings.

As industries continue to evolve towards greater sustainability and safety, Din Bellows Sealed Globe Valves stand out as a superior choice. With their advanced design and reliable performance, they are becoming increasingly popular among engineers and operators looking to enhance their systems while maintaining compliance with stringent safety regulations.

Din bellows sealed globe valves are increasingly recognized for their significant advantages in industrial settings. The primary benefit lies in their exceptional leak-proof design. The integrated bellows act as a barrier, effectively preventing medium Leakage, which is crucial for maintaining safety and environmental integrity in various applications. This characteristic is particularly important in industries where even minor leaks can lead to significant safety hazards or environmental concerns.

Moreover, Din bellows sealed globe valves contribute to enhanced operational efficiency. Their robust construction minimizes the need for regular maintenance, leading to reduced downtime and operational costs. This reliability ensures a smooth flow control in processes, allowing industries to maintain optimal performance levels. Additionally, these valves can withstand high pressures and temperatures, making them suitable for a wide range of fluids and gases used in industrial systems. Overall, their durability and efficiency positions Din bellows sealed globe valves as a smart choice for facilities aiming to improve performance while ensuring safety and compliance.

Din bellows sealed globe valves are engineered for exceptional reliability and performance in various industrial applications. The unique design of these valves incorporates a bellows seal, which provides a robust barrier against leaks while allowing for precise flow control. This is particularly beneficial in processes involving hazardous or corrosive fluids. According to a recent industry report, leakage rates in traditional valve designs can exceed 0.5% of total flow, highlighting the need for advanced sealing technologies like the bellows seal to mitigate environmental and safety risks.

The functionality of Din bellows sealed globe valves is significantly enhanced by their construction. The bellows are typically made from high-quality materials that can withstand extreme temperatures and pressures, making them suitable for demanding applications found in the oil, gas, and chemical sectors. In fact, data indicates that valves with bellows sealing systems can prolong operational life by 30% or more compared to standard designs, markedly reducing maintenance costs and downtime. Furthermore, the design allows for easier installation and adaptability to a range of piping configurations, which is essential in complex industrial settings where space and accessibility can pose challenges.

With their superior design and functionality, Din bellows sealed globe valves offer a compelling solution for industries that prioritize safety, efficiency, and reliability in their operations. As demands for tighter regulations and sustainable practices increase, the adoption of such advanced valve solutions is likely to rise, confirming their pivotal role in modern industrial applications.

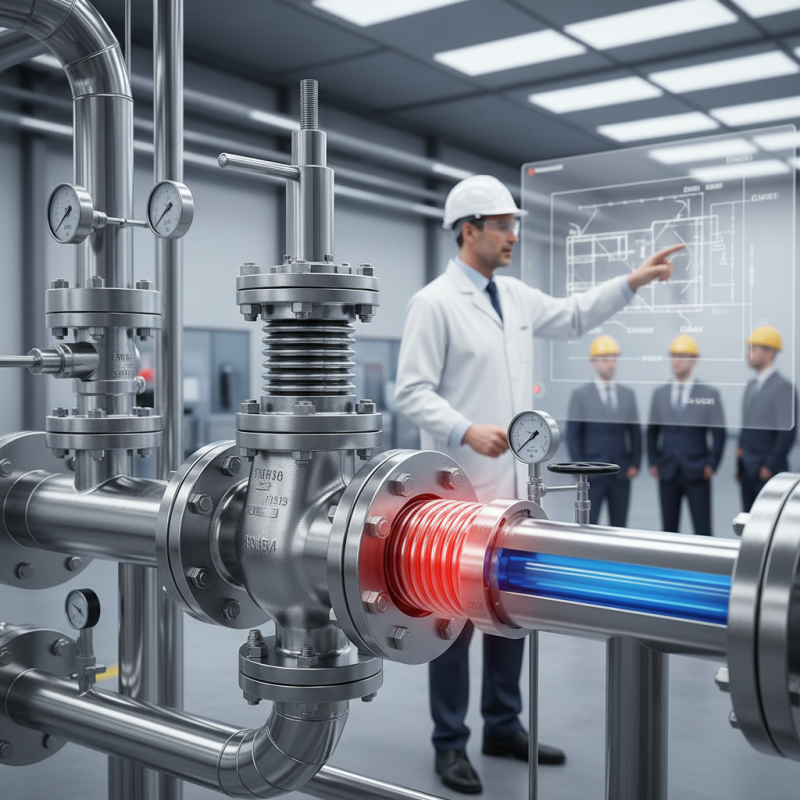

When evaluating valve options for industrial applications, it's essential to consider the functionality and reliability of different types of valves. Din bellows sealed globe valves stand out due to their unique design, which effectively prevents leakage, making them ideal for high-pressure and high-temperature environments. Compared to traditional globe valves, which often utilize packing seals that can wear out over time, the bellows seal provides a more robust solution. According to a study by the Valve Manufacturers Association, leakage rates from traditional valves can range from 0.5% to 2%, depending on the application and maintenance. In contrast, bellows sealed valves significantly reduce these leakage rates to near zero, enhancing operational safety and reducing environmental impact.

Additionally, when analyzing the differential performance of Din bellows sealed globe valves versus other valve types like ball and gate valves, the longevity and cost efficiency become evident. While ball valves are known for their quick shut-off capabilities, they may not withstand extreme operating conditions as effectively as bellows sealed valves. In environments where corrosive or costly fluids are involved, the initial higher investment in bellows sealed designs can lead to lower lifetime costs by mitigating leaks and reducing maintenance needs. A report from the International Society of Automation noted that the total cost of ownership for bellows sealed valves can be reduced by 15-25% over a decade compared to conventional valve types, illustrating their economic advantage in the long run.

Din bellows sealed globe valves are increasingly recognized for their critical role across various industrial applications. These valves are particularly effective in industries that demand strict control over fluid flow while minimizing leakage risks. In the chemical processing and pharmaceutical sectors, for example, the integrity of materials is paramount. The design of bellows sealed valves ensures that no fluid escapes, safeguarding against contamination and maintaining product purity. This feature is crucial, where even minute leaks can lead to significant safety hazards and costly downtime.

Additionally, the power generation and oil and gas industries benefit greatly from the reliability of din bellows sealed globe valves. These sectors often operate under extreme pressure and temperature conditions, making the durability of valve components essential. The ability of bellows sealed globe valves to maintain a tight seal reduces the possibility of leaks while providing robust performance under harsh operating conditions. As sustainability becomes more significant, these valves also contribute to reducing emissions and enhancing operational efficiency, aligning with modern environmental standards in industrial practices.

Din bellows sealed globe valves are increasingly recognized for their efficiency and reliability in various industrial applications. A 2021 report by the Global Valve Market Research conducted by the Market Research Future indicated that the demand for reliable valve solutions will increase by 5.3% annually, particularly in sectors such as oil and gas, water treatment, and chemical processing. The bellows seal design minimizes leakage risks, enhancing operational safety, which is paramount in environments where hazardous substances are handled.

Case studies reveal that industries employing Din bellows sealed globe valves experience significant operational efficiencies. For instance, a recent case study in the chemical manufacturing sector showed a 20% reduction in leakage incidents after transitioning to bellows sealed valves, translating to lower environmental risk and improved compliance with safety regulations. Similarly, in a power generation facility, the adoption of these valves led to an uptick in overall system performance, with a remarkable 15% increase in energy efficiency noted during routine operational audits. Such advancements underscore the strategic importance of investing in durable and dependable valve solutions to meet regulatory standards and maximize operational output.

| Application | Type of Fluid | Temperature (°C) | Pressure (bar) | Efficiency Improvement (%) | Reliability Rating (1-10) |

|---|---|---|---|---|---|

| Chemical Processing | Acids | 75 | 5 | 20 | 9 |

| Water Treatment | Water | 25 | 3 | 15 | 8 |

| Oil & Gas | Crude Oil | 100 | 10 | 25 | 10 |

| Pharmaceuticals | Solvents | 50 | 4 | 30 | 9 |