+86 19720579616

+86 19720579616

Zalo

Zalo

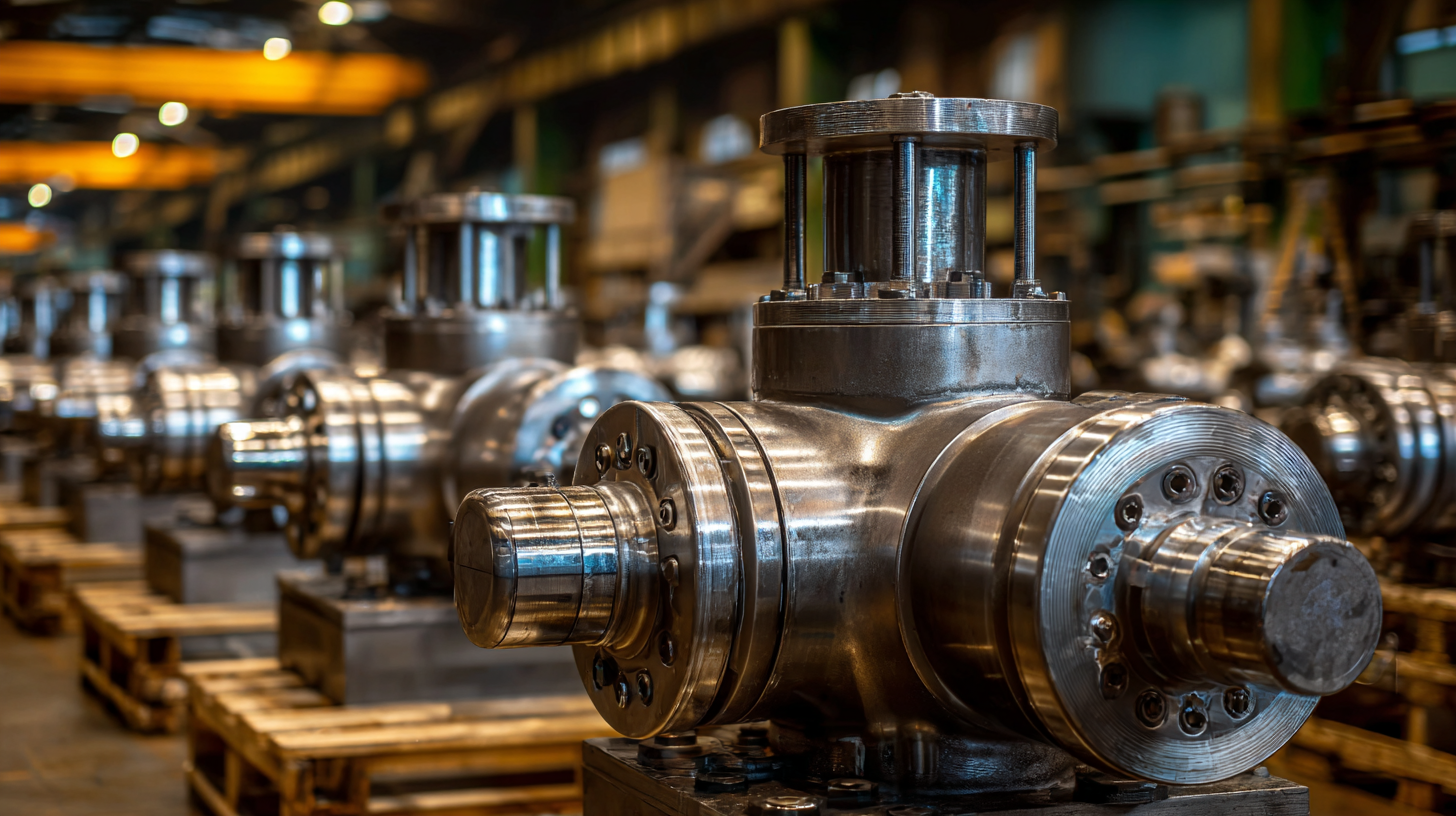

In the competitive landscape of industrial applications, the selection of high-quality components is paramount, particularly when it comes to valves. According to a report by MarketsandMarkets, the global valve market is expected to reach USD 106.24 billion by 2025, with an increasing emphasis on efficiency and reliability across various sectors. Among these critical components, API 602 forged steel valves stand out due to their exceptional strength, durability, and ability to withstand high-pressure environments. Sourced from China's top manufacturing facilities, these valves represent a seamless blend of advanced engineering and stringent quality control, making them a preferred choice for industries worldwide. The trust forged through consistent performance and reliability has made API 602 forged steel valves a cornerstone in the infrastructure of global industries, ensuring safety and efficiency in operations.

API 602 forged steel valves are increasingly recognized as a vital component across a range of critical industries, including oil and gas, petrochemicals, and power generation. According to a recent report from Research and Markets, the global valve market is projected to grow from $75 billion in 2021 to $93 billion by 2028, with forged steel valves, particularly those meeting API standards, accounting for a significant share of this expansion. The robustness and reliability of API 602 valves make them indispensable in scenarios where safety and efficiency are paramount. Their ability to withstand high pressures and temperatures ensures operational integrity, which is crucial in sectors that handle hazardous materials.

In addition, API 602 forged steel valves are compliant with stringent industry standards, ensuring they meet the rigorous specifications required in critical applications. For instance, the American National Standards Institute (ANSI) highlights the importance of using such high-performance valves in refinery operations to minimize downtime and enhance productivity. By utilizing API 602 valves, industries can contribute to cost savings; a study conducted by the National Institute of Standards and Technology (NIST) found that implementing high-quality valves can reduce leakage by up to 95%, significantly lowering maintenance costs and improving overall system efficiency. This combination of durability and compliance makes API 602 forged steel valves a top choice for businesses looking to optimize their operations in challenging environments.

The forged steel valve market, particularly in the oil and gas sector, is witnessing significant growth, driven by various dynamic factors. According to a recent report by Market Research Future, the global forged steel valve market is projected to showcase a compound annual growth rate (CAGR) of approximately 5.6% from 2022 to 2030. This growth is primarily fueled by the increasing demand for energy and a simultaneous need for efficient and durable equipment to handle high-pressure applications in the industry.

Furthermore, the shift towards sustainable energy solutions has prompted oil and gas companies to invest in advanced technologies, enhancing the need for high-quality forged steel valves. The International Energy Agency (IEA) highlights that global investment in oil and gas upstream projects is expected to reach $480 billion by 2025, underscoring the industry's commitment to maintaining and upgrading infrastructure. In line with this, forged steel valves, known for their strength, reliability, and resistance to high temperatures and pressures, are becoming the preferred choice for companies looking to optimize performance and ensure operational safety.

| Reason | Details | Market Trend | Growth Projection (2023-2028) |

|---|---|---|---|

| High Durability | Forged steel valves provide superior strength and resistance to corrosion. | Increasing demand in harsh environments. | 7% CAGR |

| Cost-Effectiveness | Longer lifespan reduces replacement costs. | Price stability in raw materials. | 5% CAGR |

| Wide Application Range | Suitable for various industries including oil, gas, and water treatment. | Diverse industry growth driving demand. | 6% CAGR |

| Regulatory Compliance | Meets international standards for safety and performance. | Stricter regulations boosting the market. | 8% CAGR |

| Innovation & Technology | Continuous advancements improve efficiency and safety. | Technology adoption growing rapidly. | 9% CAGR |

| Easy Maintenance | Simplified design allows for quick servicing. | Maintenance-friendly solutions gaining popularity. | 4% CAGR |

| Sustainability | Recyclable materials and energy efficiency. | Growing focus on sustainable practices. | 6% CAGR |

When it comes to high-pressure applications, the durability and performance of API 602 forged steel valves stand out, making them an essential choice for global industries. These valves are designed to withstand extreme conditions, ensuring longevity and reliability. Their robust construction allows them to maintain tight seals even under high pressure, which is crucial for preventing leaks and reducing fugitive emissions in various applications. This aspect is particularly important as industries increasingly focus on adhering to stringent environmental regulations.

In light of recent developments, such as the introduction of test methods for qualifying quarter-turn valves for low emissions service, the importance of selecting the right valve has never been clearer. API 602 valves not only meet rigorous performance standards but are also evaluated for their effectiveness in minimizing emissions, aligning with the industry's push toward more sustainable practices. By investing in high-quality valves, industries can enhance operational efficiency while ensuring compliance with environmental standards. The selection of API 602 valves is thus a strategic decision that can lead to improved overall system performance and environmental stewardship.

Forged steel valves, particularly those meeting the API 602 standard, have gained recognition for their remarkable cost efficiency in global industries. According to a report from the International Journal of Industrial Science, companies can reduce operational expenses by up to 30% when utilizing forged steel valves compared to traditional materials. This significant saving is attributed to the superior strength and durability of forged steel, which minimizes maintenance requirements and replacement costs over time.

Moreover, forged steel valves have a higher resistance to corrosion and wear, extending their life cycle significantly. A study conducted by the Valve Manufacturers Association revealed that using high-quality forged steel valves can lead to a decrease in downtime by as much as 25%. This reduction in downtime not only enhances productivity but also contributes to further operational savings.

As industries increasingly prioritize cost-efficiency and longevity, the adoption of forged steel valves continues to rise, demonstrating their undeniable value in reducing overall expenses while maintaining performance standards.

When it comes to manufacturing forged steel valves, particularly API 602 models, understanding the quality standards across different regions is crucial.

Chinese manufacturers have rapidly scaled their production, often focusing on cost efficiency and high-volume output. However, there are concerns regarding the consistency and quality of these valves.

In contrast, Western manufacturers typically prioritize stringent quality control measures and compliance with global standards, resulting in a more reliable product. This difference in manufacturing ethos can significantly impact the performance and longevity of valves used in critical applications.

Chinese manufacturers have rapidly scaled their production, often focusing on cost efficiency and high-volume output. However, there are concerns regarding the consistency and quality of these valves.

In contrast, Western manufacturers typically prioritize stringent quality control measures and compliance with global standards, resulting in a more reliable product. This difference in manufacturing ethos can significantly impact the performance and longevity of valves used in critical applications.

The debate surrounding quality comparisons between Chinese and Western manufacturers essentially boils down to how each region approaches innovation and quality assurance. While Western companies may be slower to market due to rigorous testing and certification processes, their products often exhibit greater durability and reliability in harsh industrial environments. In contrast, Chinese manufacturers are increasingly adopting advanced technologies and collaborations with international firms to enhance their product offerings. Therefore, selecting the right valve requires careful consideration of both manufacturer practices and the specific needs of the industry, ensuring that the chosen product meets the highest standards of performance and safety.