+86 19720579616

+86 19720579616

Zalo

Zalo

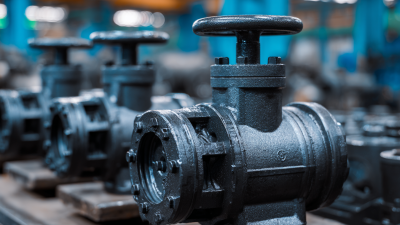

When undertaking a project that involves the use of valves, selecting the right type is crucial for ensuring optimal performance and efficiency. Among the various options available, the Bs 5163 Non-Rising Stem Resilient Seated Gate Valves stand out for their design and functionality. These valves are engineered to provide a reliable sealing mechanism and are particularly beneficial in applications where space constraints and maintenance accessibility are concerns. Their non-rising stem feature is designed to save vertical space while allowing smooth and easy operation, making them a perfect choice for a range of piping systems. In this guide, we will explore essential factors to consider when choosing Bs 5163 Non-Rising Stem Resilient Seated Gate Valves for your project, ensuring that you make an informed decision that meets your specific needs and enhances system integrity.

When selecting a BS 5163 non-rising stem resilient seated gate valve for your project, it's essential to understand its key specifications. These valves are designed to provide reliable service in various applications, primarily in water distribution systems. A critical feature of these valves is their resilient seating, which enhances sealing performance and reduces the likelihood of leakage. Additionally, the non-rising stem design allows for installation in spaces with height restrictions, making them suitable for underground or confined applications.

Another important specification is the valve's pressure rating and temperature tolerance. Knowing the operating conditions of your system will help you choose a valve that can withstand potential stresses. Material selection is equally crucial; valves made from ductile iron or other robust materials ensure durability and longevity. Additionally, the connection types, such as flanged or threaded options, must align with your piping requirements. By carefully assessing these specifications, you can ensure that you select a BS 5163 non-rising stem resilient seated gate valve that meets the specific needs of your project.

When selecting the appropriate BS 5163 non-rising stem resilient seated gate valve for your project, evaluating fluid types and pressure ratings is crucial. Different fluids exhibit varying characteristics, such as corrosiveness and temperature, which can significantly impact valve performance. For instance, water and other non-aggressive fluids might require less robust materials, while acids or other corrosive substances could necessitate specialized coatings or construction materials to ensure longevity and reliability.

In addition to fluid compatibility, the pressure rating of the valve must align with the system's operational requirements. It's vital to match the valve’s pressure rating with the maximum anticipated pressure in the pipeline to prevent failure during operational conditions. Choosing a valve with an inadequate pressure rating can lead to catastrophic results, including leaks or bursts. Therefore, a thorough understanding of both the fluid characteristics and the pressure parameters is essential for making a well-informed valve selection that ensures safety and efficiency in your project.

When selecting the appropriate BS 5163 non-rising stem resilient seated gate valve for your project, assessing the material composition is crucial for ensuring both durability and compatibility with the intended application. The valve body, often crafted from cast iron or ductile iron, must be able to withstand the pressures and environmental conditions it will encounter. Different coatings, such as epoxy, can enhance resistance to corrosion, making them suitable for harsh environments where exposure to water or chemicals is a concern.

Compatibility with the fluids being handled is another critical factor. The elastomer used for the seating material, commonly EPDM or NBR, must be chosen based on the specific media—water, oil, or chemicals—being transported. Understanding the chemical properties and temperature range of these fluids is essential for preventing material degradation over time. Thus, a thoughtful consideration of these material aspects not only prolongs the lifespan of the valve but also ensures the overall reliability of the system in which it operates.

When selecting a Bs 5163 non-rising stem resilient seated gate valve, understanding installation requirements is crucial for ensuring optimal performance. According to the American Water Works Association (AWWA), proper installation involves verifying the valve's orientation, ensuring that it is fitted in a horizontal position (when applicable), and confirming that the surrounding pipework is adequately supported. Additionally, the spacing between the valve and other components should allow for easy access, especially for maintenance and operational checks. Failure to adhere to these requirements may lead to operational failures, ultimately impacting project timelines and costs.

Maintenance procedures are equally important for the longevity and reliability of gate valves. A recent industry report by Frost & Sullivan highlights that inadequate maintenance can reduce valve lifespan by up to 30%. Regular inspections should focus on the valve's sealing surface, looking for wear or damage, and checking the stem and actuator functionality. The AWWA recommends a biannual maintenance schedule for gate valves, emphasizing the importance of lubrication and testing for leaks. By following these practices, project managers can ensure their chosen gate valves not only meet initial installation standards but also provide lasting operational efficiency.

When selecting a Bs 5163 non-rising stem resilient seated gate valve for your project, understanding the cost-effectiveness and long-term performance of various brands is crucial. According to a 2022 report by the American Water Works Association, the total lifecycle cost of gate valves can exceed the initial purchase price by 50% or more when maintenance, operational efficiency, and potential downtime are considered. Thus, investing in a reputable brand known for durability can lead to significant savings over time.

Brands like Brand A and Brand B have consistently shown better performance in stress tests, with Brand A reporting a failure rate of only 2% after 20 years of use, compared to 10% for Brand B, as per the latest industry analysis from the Valve Manufacturers Association. Furthermore, a comparative study published in the Journal of Fluid Engineering indicated that resilient seated designs significantly reduce leakage rates, which can lead to further operational costs. By evaluating these critical factors, project managers can make informed decisions that balance upfront costs with the benefits of long-term reliability and performance.

| Valve Brand | Cost ($) | Pressure Rating (PSI) | Material | Warranty (Years) | Expected Lifespan (Years) |

|---|---|---|---|---|---|

| Brand A | 100 | 150 | Cast Iron | 5 | 25 |

| Brand B | 120 | 200 | Ductile Iron | 6 | 30 |

| Brand C | 90 | 125 | Steel | 5 | 20 |

| Brand D | 110 | 175 | PVC | 7 | 25 |