+86 19720579616

+86 19720579616

Zalo

Zalo

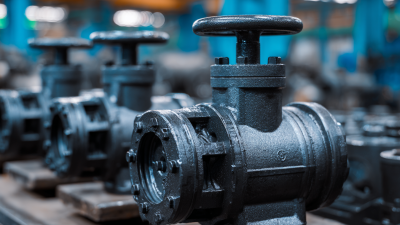

In the realm of industrial applications, choosing the right equipment is crucial for maintaining efficiency and ensuring safety. One of the pivotal components in many systems is the API Bellows Sealed Globe Valves, known for their ability to provide a leak-tight seal and resist corrosive environments. According to a recent market report, the global valve market is projected to reach USD 90 billion by 2025, indicating a growing demand for high-performance valves such as API Bellows Sealed Globe Valves.

These valves are particularly favored in industries like oil and gas, chemical processing, and water treatment due to their robust design and reliability. However, selecting the appropriate model requires careful consideration of various factors, including pressure and temperature ratings, material compatibility, and specific operational requirements. This checklist aims to guide industrial professionals in making informed decisions to optimize their systems with the right API Bellows Sealed Globe Valves.

When selecting the right API bellows sealed globe valves for industrial applications, it’s essential to grasp their fundamental characteristics and advantages. API bellows sealed globe valves are specifically designed to prevent leakage, enhancing safety and reliability in critical processes. According to a report by the Global Valve Market, the demand for these valves is projected to grow at a CAGR of 5.2% from 2021 to 2026, driven by stringent safety regulations and the increasing need for efficient sealing solutions in sectors such as oil and gas, chemicals, and water treatment.

These valves utilize a bellows assembly that effectively isolates the valve stem from the process fluid, significantly minimizing the risk of contamination and potential hazards. A comparative study by ResearchAndMarkets indicates that industries utilizing bellows sealed valves experience up to a 30% reduction in maintenance costs due to lower failure rates compared to traditional valves. This reliability not only enhances operational efficiency but also extends the lifespan of the equipment, resulting in long-term cost savings and sustainability for industrial operations.

| Parameters | Description | Options |

|---|---|---|

| Valve Size | Determines the flow capacity | 1" to 16" |

| Pressure Rating | Maximum allowable working pressure | Class 150 to Class 2500 |

| Material | Valve body and bellows material | Stainless Steel, Carbon Steel, Alloy |

| Temperature Range | Operating temperature limits | -20°C to 450°C |

| End Connections | Type of connections for piping | Flanged, Threaded, Welded |

| Application | Intended use in industry | Chemical Processing, Oil & Gas, Water Treatment |

When selecting API bellows sealed globe valves for your industrial applications, several key factors must be considered to ensure optimal performance and reliability. First and foremost, understanding the operational environment is crucial. Evaluate the pressure and temperature conditions that the valves will be exposed to, as this will help you determine the appropriate materials and designs that can withstand these conditions.

Another important consideration is the size and flow requirements of your system. It's essential to choose valves that are appropriately sized to maintain system efficiency and prevent unnecessary energy loss. Aligning the valve specifications with your piping system is vital for seamless integration and operation.

**Tips:** Always consult with manufacturers or industry experts to gain insights into the best practices for selection and maintenance of API bellows sealed globe valves. Additionally, reviewing performance ratings and feedback from previous users can help you make more informed decisions. Don't overlook the importance of warranties and support services offered by suppliers, as these can be invaluable in case of future issues.

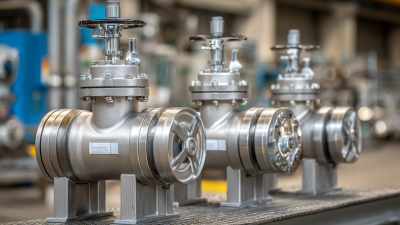

When selecting API bellows sealed globe valves for industrial applications, the choice of materials and designs plays a crucial role in optimizing performance and longevity. Various materials, such as stainless steel, carbon steel, and special alloys, offer different strengths and corrosion resistance levels, which directly affect the valve's suitability for specific environments. For instance, stainless steel valves are ideal for corrosive fluids, while carbon steel may suffice for less aggressive applications. Understanding the fluid characteristics, operating conditions, and potential exposure to chemicals will guide you in choosing the appropriate material.

Design is another critical factor to consider. The variation in design can influence the valve's flow characteristics, pressure ratings, and overall reliability. Standard designs may work for general applications, but specialized designs, such as those featuring enhanced sealing or pressure control capabilities, are necessary for more demanding conditions. Additionally, leveraging advanced design principles can improve energy efficiency and reduce maintenance needs. By carefully comparing the options in materials and designs, you can ensure that the selected valve meets your specific industrial requirements and contributes to a smooth operational workflow.

API bellows sealed globe valves are essential components in various industrial applications, particularly where leakage prevention and system integrity are paramount. One common application is in the oil and gas industry, where these valves help manage the flow of aggressive media under high pressure and temperature conditions. Their design minimizes the risk of contamination, which is critical in processes involving hazardous materials. By utilizing bellows technology, these valves eliminate the traditional packing, thereby providing a robust sealing solution that significantly reduces the chances of leakage.

Another significant use case for API bellows sealed globe valves is in the chemical processing industry. In this sector, precise flow control and safety are crucial due to the potentially volatile nature of the chemicals involved. The enhanced sealing capabilities of bellows sealed valves ensure that even under fluctuating pressures, there is minimal risk of chemical escape, thus safeguarding both the equipment and personnel. Additionally, these valves are suitable for applications involving steam and thermal fluids, where their resistance to thermal cycling further enhances their reliability and performance in demanding environments.

When it comes to maintaining bellows sealed globe valves, regular inspections are essential to ensure their longevity and optimal performance. A study by the Valve Manufacturers Association indicates that improper maintenance can lead to a 20% decrease in valve efficiency over time. To prevent this, routine checks for leaks and wear on the bellows are crucial. Look for any signs of corrosion or damage that could compromise the seal, as this is a common failure point in these valves.

Troubleshooting issues with bellows sealed globe valves often involves analyzing changes in performance metrics. According to a report from the Global Valve Market Insights, improper installation can lead to a 15% increase in the chances of failure. If you notice irregular pressure readings or flow inconsistencies, consider the installation angle and the overall configuration. A thorough re-evaluation can often pinpoint the cause of the problem. Additionally, ensuring that the valves are compatible with the media they control is critical; corrosive substances can significantly shorten the life of bellows seals, leading to costly downtimes.