+86 19720579616

+86 19720579616

Zalo

Zalo

In the realm of fluid control and management, selecting the appropriate valves is critical for ensuring system efficiency and reliability. The Bs 5163 Non-Rising Stem Resilient Seated Gate Valves have become increasingly prominent due to their robust design and versatility in various applications, including water supply and wastewater management. According to a report by Global Market Insights, the demand for resilient seated gate valves is projected to grow significantly, fueled by the escalating need for efficient water infrastructure and sustainable solutions, with the market expected to reach USD 3 billion by 2026. This growth highlights the importance of making informed choices when selecting valves that meet operational requirements while adhering to industry standards. Understanding the key factors in choosing the right Bs 5163 Non-Rising Stem Resilient Seated Gate Valves is essential for engineers and project managers aiming to optimize performance and minimize long-term costs.

When selecting the appropriate BS 5163 non-rising stem resilient seated gate valves, understanding the importance of adhering to BS 5163 standards is crucial for effective water management systems. These standards ensure that the valves meet specific performance criteria, promoting efficiency and safety in water distribution. According to industry reports, adherence to such standards can significantly reduce the risk of leaks and failures, which can lead to costly repairs and operational downtime.

When selecting the appropriate BS 5163 non-rising stem resilient seated gate valves, understanding the importance of adhering to BS 5163 standards is crucial for effective water management systems. These standards ensure that the valves meet specific performance criteria, promoting efficiency and safety in water distribution. According to industry reports, adherence to such standards can significantly reduce the risk of leaks and failures, which can lead to costly repairs and operational downtime.

Tips: Always verify that the valves you are considering have been tested and certified under the relevant BS 5163 standards. Look for specifications indicating pressure ratings and durability that align with your specific application needs.

Additionally, recent developments in certification standards, like the NSF/ANSI guidelines for UV LED technology in drinking water treatment, highlight the growing emphasis on safety and compliance in water management. Selecting resilient seated gate valves that conform to BS 5163 not only guarantees quality but also aligns with the best practices established in the industry, ensuring a robust water management system.

Tips: Consult with experienced professionals and refer to comprehensive industry reports to ensure you are making informed decisions based on the latest standards and innovations in the field.

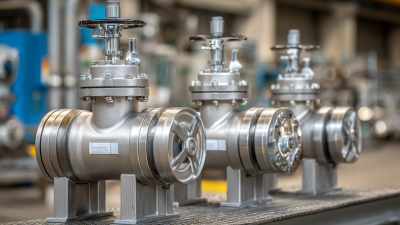

When selecting the right BS 5163 non-rising stem resilient seated gate valves, it’s essential to consider several key features that influence performance and longevity. One of the primary factors is the valve body material. Materials like ductile iron offer excellent durability and resistance to corrosion, which is vital in various applications, from water supply systems to industrial processes. Additionally, ensure that the valve has a resilient seating surface, as this component significantly affects the seal quality and reduces the risk of leaks.

Another critical feature to evaluate is the valve size and connection type. It’s imperative to choose a valve that fits seamlessly into your existing piping system and meets pressure requirements. Non-rising stem designs are particularly advantageous in space-constrained areas, eliminating the need for additional vertical clearance. Finally, look for reliable certifications and compliance with industry standards, as these can guarantee the valve's reliability and efficiency in real-world applications. Investing time in understanding these features will help you make an informed decision that aligns with your specific needs.

When selecting Bs 5163 Non-Rising Stem Resilient Seated Gate Valves, understanding the material durability is crucial for long-term performance. Materials commonly used in gate valves, such as ductile iron, stainless steel, and various blends of elastomers, each exhibit distinct properties that affect their lifespan and functionality. A comparative analysis shows that ductile iron valves showcase superior strength and resistance to environmental conditions compared to traditional cast iron. Additionally, they offer better corrosion resistance when coated with suitable protective layers, making them more reliable in both water and wastewater applications.

On the other hand, stainless steel gate valves are celebrated for their exceptional durability, particularly in harsh chemical environments. They maintain structural integrity even under extreme temperatures, reducing the risk of failure. However, cost considerations are a significant factor, as stainless steel options tend to be pricier. By weighing the specific conditions and requirements of your application against the durability characteristics of these materials, you can make an informed decision that optimizes both performance and cost-effectiveness in your gate valve selection.

When selecting Bs 5163 non-rising stem resilient seated gate valves, one of the most critical factors is sizing and flow considerations. The correct valve size ensures that the system operates efficiently, preventing issues like excessive pressure drops or flow restrictions. It's essential to match the valve’s diameter with the pipe size and to consider the flow rate requirements of your system. This helps in achieving optimal performance and longevity of both the valve and the entire piping system.

Tip: Perform a thorough assessment of your system's flow requirements before selecting a valve. Calculate the expected flow rate and pressure conditions to determine the most suitable valve size. Additionally, consider the characteristics of the fluid being transported, as different fluids may affect the valve's performance capacity.

Another vital aspect to consider is the installation and maintenance space available. In tight installation environments, it may be more appropriate to choose a valve with a smaller overall footprint. Ensuring adequate space for maintenance can also be crucial for operational efficiency.

Tip: Always allow for sufficient clearance around the valve for maintenance access, as this will save time and resources in the long run. Review manufacturer's guidelines for installation to enhance the reliability and functionality of the gate valves in your system.

As the industry continues to evolve, innovations in gate valve technology are becoming pivotal in enhancing performance, efficiency, and reliability. Recent advancements include the integration of smart technology into gate valves, which allows for real-time monitoring and automated control. This not only optimizes operation but also facilitates predictive maintenance, reducing downtime and operational costs. The ability to remotely manage these valves makes them invaluable in complex infrastructures where manual monitoring may be challenging.

Furthermore, there is a growing emphasis on sustainable materials and manufacturing processes in the production of resilient seated gate valves. This shift is driven by the increasing demand for environmentally friendly solutions within the industry. Innovations such as biodegradable seals and coatings designed to withstand corrosive environments are becoming more common, allowing for longer-lasting products that minimize environmental impact. As these technologies develop, they promise to reshape the landscape of gate valve applications, meeting both current and future industry demands.

| Feature | Description | Impact on Selection |

|---|---|---|

| Material | Cast iron, ductile iron, or stainless steel options available | Choosing the right material affects durability and application suitability |

| Size | Available in various sizes from 2" to 48" | Size selection impacts flow capacity and installation compatibility |

| Pressure Rating | Standard ratings from PN10 to PN25 | Influences the valve's ability to handle specific fluid conditions |

| End Connections | Flanged, threaded or welded connections | Affects compatibility with existing pipelines and installation ease |

| Stem Design | Non-rising stem design for space-constrained areas | Provides benefits for underground or limited access installations |

| Seat Type | Resilient seated for effective sealing | Enhances sealing performance and reduces leakage risk |

| Innovative Features | Smart sensors and remote monitoring capabilities | Improves maintenance efficiency and operational reliability |