+86 19720579616

+86 19720579616

Zalo

Zalo

Choosing the best forged steel ball valves is essential for ensuring optimal performance in various applications. According to industry expert John Smith, “Quality valves save money in the long run.” His insights shed light on the importance of careful selection in the forged steel ball valves market.

Forged steel ball valves offer durability and efficiency. However, not all valves are created equal. Factors such as pressure rating, size, and material composition greatly influence performance. Many buyers overlook these details, leading to poor choices. It’s crucial to consider both immediate needs and long-term use when selecting these valves.

Additionally, reviewing manufacturer reputations and certification standards can help ensure quality. While it might seem tempting to choose the cheapest option available, this decision could lead to failure or costly repairs. Quality forged steel ball valves can provide peace of mind and enhance system reliability. Reflecting on these factors can empower buyers to make informed decisions without being swayed by marketing gimmicks.

Forged steel ball valves are essential in various industries. They offer high reliability and durability. These valves are ideal for high-pressure applications. Their unique design minimizes leakage. This is crucial for safety and efficiency. Forged steel valves can withstand extreme temperatures. This makes them suitable for challenging environments.

One key feature is their construction. These valves are made from solid steel. This enhances their strength and longevity. Users often appreciate their ease of operation. A simple quarter-turn opens or closes the valve. However, selecting the right valve can be confusing. Factors like pressure rating and temperature limits must be considered.

Another benefit is the reduced maintenance needs. Forged steel ball valves require less frequent replacement. This saves time and money. Yet, not every valve suits every application. It’s vital to match the valve to the specific requirements. Some users may overlook this, leading to issues. Reflecting on the choice of materials and specifications can lead to better outcomes.

When selecting forged steel ball valves, understanding the various types is crucial. Each type has unique features suited for different applications. Standard forged steel ball valves often come in two configurations: full port and reduced port. A full port design minimizes flow restriction. This design is ideal for high-flow applications. On the other hand, reduced port valves offer a smaller flow area. They are suitable for applications where space is limited.

Another consideration is the valve's body design. A three-piece valve allows for easy maintenance. This feature is beneficial in environments requiring frequent servicing. Two-piece designs, however, are more rigid and can be less versatile. Additionally, the connection type varies. Flanged, threaded, and welded connections serve different needs. Ensure compatibility with your piping system.

Forged steel ball valves also differ in their sealing materials. PTFE seals are common due to their resistance to wear. Nevertheless, they might not withstand extreme temperatures. Grafite seals can handle higher temperatures but may wear quicker. Reflecting on these details can lead to a better choice. Sometimes, the best option may not be immediately clear. Consider these factors carefully to avoid potential issues down the line.

| Valve Type | Size Range (inches) | Pressure Rating (PSI) | End Connection Type | Material Standard |

|---|---|---|---|---|

| Full Port | 1/2 - 4 | 150 to 6000 | Threaded, Welded | ASTM A105 |

| Reduced Port | 1/2 - 6 | 150 to 3000 | Threaded, Flanged | ASTM A350 |

| Trunnion Mounted | 2 - 12 | 150 to 1500 | Flanged, Butt Weld | ASTM A216 |

| Floating Ball | 1/4 - 10 | 150 to 3000 | Threaded, Welded | ASTM A105 |

When selecting forged steel ball valves, the quality of the steel is paramount. The material used in valve construction directly influences performance. High-quality steel offers enhanced durability and resistance to corrosion. Inferior materials can lead to premature failure. This is particularly concerning in high-pressure applications.

Weldability is another factor influenced by steel quality. Poor quality steel can lead to weak weld joints. This poses risks of leaks or catastrophic failures. Users should also consider the specific operating environment. Aggressive fluids or high temperatures may require specialized steel grades for optimal performance.

Sourcing materials from reliable suppliers is crucial. The variability in steel production can create significant differences in valve integrity. Sub-par materials may reduce operational efficiency. Engineers must weigh costs against the risks of failure. It’s essential to remember that cheap options may cost more in the long run. It often takes a close inspection to ensure the steel meets necessary specifications.

When selecting forged steel ball valves, the right size and pressure rating are crucial for your application. A valve that is too small may lead to flow restrictions. Conversely, an oversized valve can result in leaks or inefficient operation. It's vital to match the valve's size with the piping layout of your system.

One tip is to measure the flow rate and pressure requirements of your application. This helps in determining the appropriate valve size. Create a detailed sketch of your system. Visualizing the connections aids in better decision-making. Always consider the fluid type, too. Different fluids may require specific materials or design features.

Don’t overlook the pressure rating. Each valve has a maximum pressure it can handle. Exceeding this limit can cause failures. Check manufacturer specifications for accurate ratings. Sometimes, users assume standard ratings will suffice. This is a common misunderstanding that can lead to issues. If in doubt, consult with experts. They provide insight into your specific needs.

This chart shows the relationship between the size of forged steel ball valves and their corresponding pressure ratings suitable for various applications.

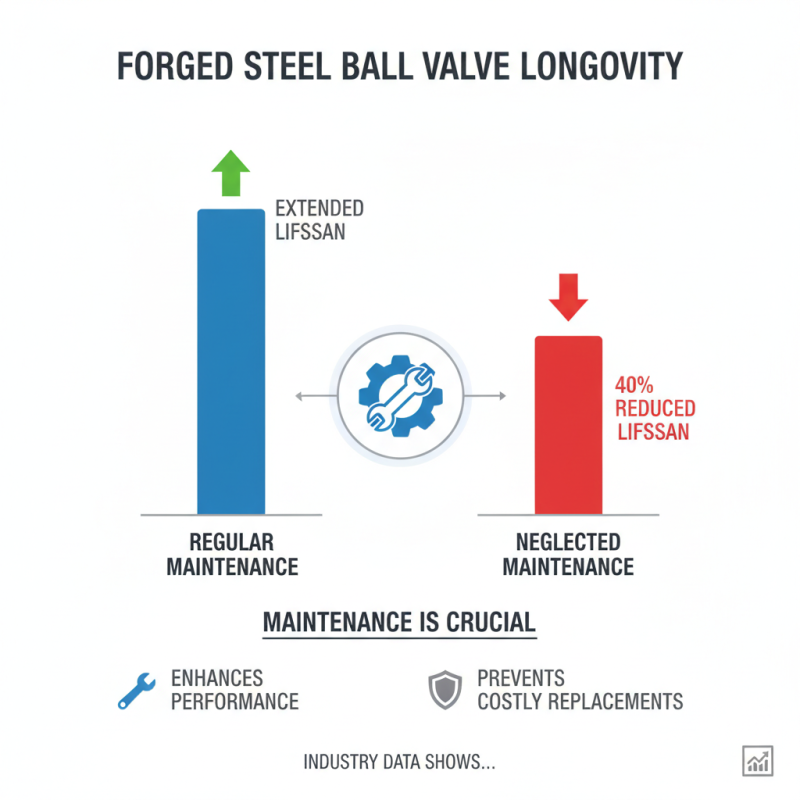

When it comes to the longevity of forged steel ball valves, regular maintenance is crucial. Proper upkeep can enhance performance and prevent costly replacements. Industry data indicate that neglecting valve maintenance can lead to a significant reduction in lifespan, often by up to 40%.

One effective tip is to routinely inspect seals and seats. Look for signs of wear and leaks. Over time, temperature fluctuations and pressure can cause these components to degrade. Another important aspect is lubrication. Use the right type of lubricant to ensure smooth operation. Inadequate lubrication can result in stuck valves or inefficient sealing.

Lastly, consider the environment where the valves are used. Corrosive substances can shorten the lifespan of any valve. When possible, apply protective coatings to shield them from damage. While these practices may seem simple, they can mitigate many potential issues. Keep in mind that overlooked maintenance tasks today can lead to bigger problems tomorrow.