+86 19720579616

+86 19720579616

Zalo

Zalo

Choosing the right valves is critical for any project. In various industrial applications, the selection of API bellows sealed globe valves can significantly impact performance. These valves provide exceptional sealing capabilities, making them suitable for high-pressure and high-temperature environments. However, not all API bellows sealed globe valves are created equal, and selecting the appropriate option can be daunting.

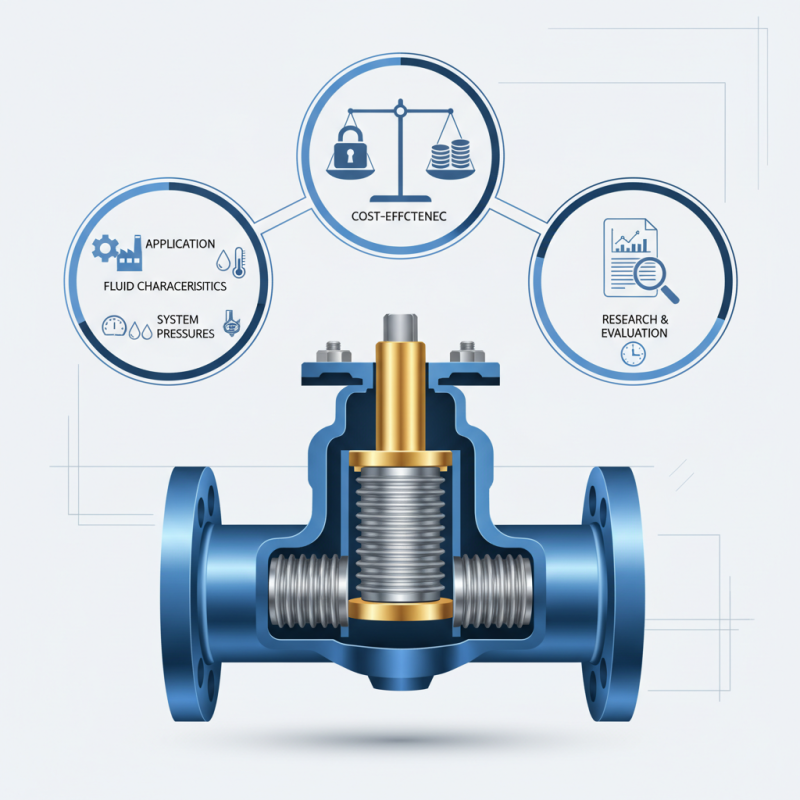

One must consider various factors during the selection process. The specific application, fluid characteristics, and system pressures all play vital roles. For instance, the materials used in these valves must resist corrosion and wear. Balance is key; while durability is important, cost-effectiveness cannot be overlooked. It's common for projects to face budget constraints, leading to potential compromises in valve quality.

In the end, thorough research and careful evaluation are essential. One should never rush the decision-making process. Take the time to analyze current industry standards and performance specifications. This will ensure the selected API bellows sealed globe valves meet the project's requirements while addressing long-term reliability and maintenance challenges.

When selecting bellows sealed globe valves, understanding API standards is crucial. The American Petroleum Institute (API) establishes regulations that ensure valve safety and efficiency. For instance, API 623 outlines the requirements for bellows sealed globe valves used in petroleum and natural gas industries. This standard focuses on preventing leakage, which is a key concern for any operation.

A report from the International Association of Oil & Gas Producers (IOGP) indicates that more than 30% of valve failures result from improper sealing. This reinforces the importance of adhering to API specifications. Selecting valves that comply with API standards can significantly reduce operational risks. The data suggests that leaks can lead to financial losses exceeding millions annually, making compliance a priority.

Investing in valves that meet API requirements may seem straightforward, but challenges remain. Not all suppliers follow these standards rigorously. Some valves may still leak, even when labeled as compliant. Procedures for testing and quality assurance can be inconsistent across manufacturers. The valve selection process thus requires careful evaluation and an understanding of the specific application to ensure longevity and reliability.

| Dimension | Description | API Standard | Material | Size Range (inches) |

|---|---|---|---|---|

| Pressure Class | The maximum pressure a valve can handle. | API 602 | Carbon Steel | 0.5 to 10 |

| Temperature Rating | The temperature range in which the valve operates efficiently. | API 599 | Stainless Steel | 1 to 12 |

| End Connections | Type of end connections suitable for the installation. | API 598 | Brass | 2 to 14 |

| Flow Coefficient (Cv) | A measure of the valve's capacity to allow fluid flow. | API 600 | Alloy Steel | 3 to 16 |

When selecting materials for bellows sealed globe valves, several key factors come into play. The material choice can dramatically affect the valve's performance and longevity. Common materials include stainless steel and brass. Each has distinct properties that must be examined closely. For example, stainless steel offers excellent corrosion resistance, while brass may not.

Temperature and pressure ratings are critical. High-temperature applications often require specialized materials. If materials can’t withstand the conditions, failure is imminent. This could lead to leaks and costly downtime. It's crucial to consider the specific environment in which the valve will operate.

Another aspect to reflect upon is the manufacturing process. Some materials can be challenging to work with. Variability in quality can occur, leading to performance inconsistencies. This highlights the significance of sourcing from reliable suppliers. A thorough evaluation of the materials in relation to project needs is essential for success.

When selecting bellows sealed globe valves for your project, pressure and temperature ratings are critical. These ratings determine how well the valve will perform in various conditions. Most industrial valves come with a pressure rating of at least 150 psi, but some can handle up to 3000 psi. For temperature, most valves operate effectively between -20°F and 400°F. However, specific applications may require higher ratings.

Understanding the application's requirements helps in decision-making. For instance, operating in a high-temperature environment means choosing a valve made from materials that can withstand heat without losing integrity. The failure rate for valves tends to increase when consistently exposed to temperatures above their maximum ratings. This insight is vital for avoiding costly downtime.

Tips: Always consult industry guidelines or standards, like those published by ASME and API, when selecting your valves. Consider how often the system will undergo pressure fluctuations. Frequent cycling can deteriorate seals faster, leading to leaks. Also, evaluate the fluid's characteristics; aggressive chemicals can require specialized materials. Keep an eye on maintenance routines as well. Regular checks can preempt failures and extend the valve's lifespan.

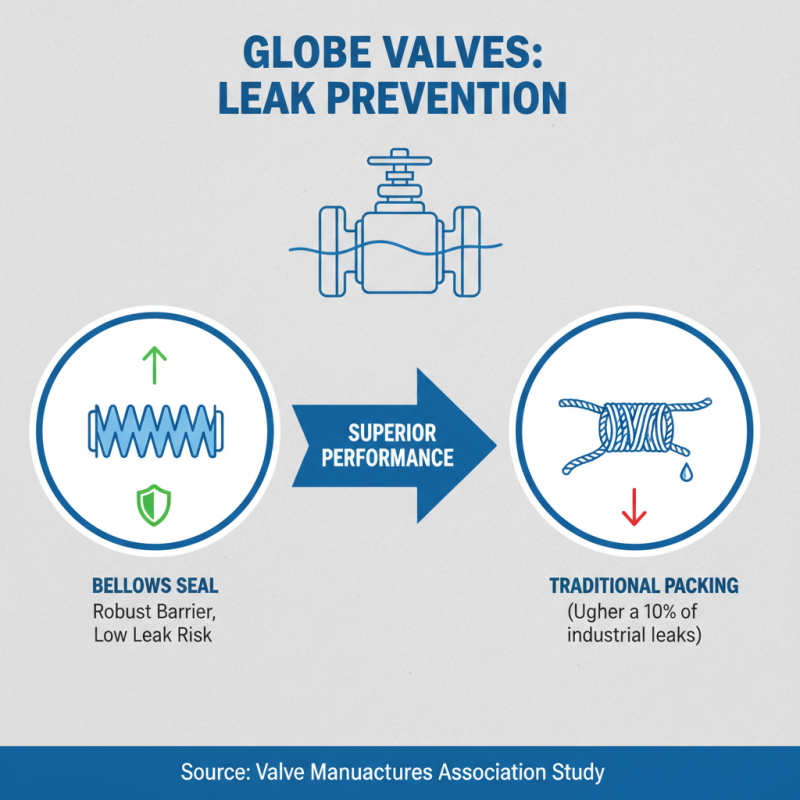

When selecting globe valves, leak prevention is crucial. The design features of these valves significantly impact their performance. A study by the Valve Manufacturers Association states that up to 10% of industrial leaks come from faulty valve seals. This figure highlights the importance of choosing the right design. Bellows seals play a key role in providing effective leak prevention. Unlike traditional packing, bellows seals offer a more robust barrier against leakage.

Another aspect to consider is the material used in manufacturing the valve. Materials such as stainless steel or high-alloyed metals can enhance the durability and reliability of the valve. A report from the American Society of Mechanical Engineers suggests that high-quality materials can reduce maintenance costs by 15% over the valve's lifespan. However, this initial investment might increase project costs. It's essential to weigh short-term expenses against long-term savings.

Additionally, the installation process should not be overlooked. Incorrect installation can lead to premature valve failure. Misalignment or improper torque settings can negate the benefits of well-designed leak prevention features. Ensuring that installation teams are well-trained can mitigate this risk. Remember, even the best-designed valve won't perform effectively if not installed correctly.

When selecting the actuation method for bellows sealed valves, consider the application environment. Different environments may require distinct actuation options.

Pneumatic actuators are commonly used. They are fast and reliable, but they need a source of compressed air. This reliance can pose challenges in remote locations.

Electric actuators are another viable choice. They offer precise control and can easily integrate with automation systems. However, they can be slower to respond. Troubleshooting can also be more complicated.

Hydraulic actuators provide powerful options for larger valves. They must be managed carefully, as oil leaks can occur.

It is important to assess the specific needs of your project. Each actuator type has its strengths and weaknesses. Choose one that aligns with the operational requirements. Take time to weigh the pros and cons. The right choice will significantly impact the efficiency and reliability of your system.