+86 19720579616

+86 19720579616

Zalo

Zalo

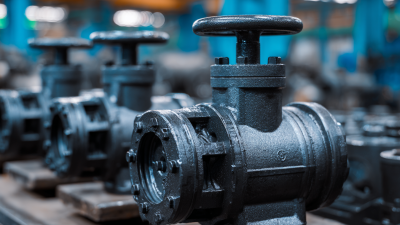

The selection of gate valves is critical in ensuring the reliability and effectiveness of fluid control in various industrial applications. Among the diverse range of options available, the Din 3352 F4 Resilient Seated Gate Valves have emerged as a preferred choice due to their robust design and exceptional sealing capabilities. According to a market research report by Global Market Insights, the gate valve market is expected to exceed $5 billion by 2026, driven by the increasing demand for resilient materials in infrastructure development. This growth highlights the importance of choosing the right valve, as the quality of valve components directly influences operational efficiency and maintenance costs. With their resilience to environmental stressors and superior performance metrics, understanding the key aspects of Din 3352 F4 Resilient Seated Gate Valves is essential for professionals looking to optimize their systems and ensure long-term functionality. This article presents the ultimate checklist to guide you through the decision-making process, ensuring you make an informed choice.

The selection of gate valves is critical in ensuring the reliability and effectiveness of fluid control in various industrial applications. Among the diverse range of options available, the Din 3352 F4 Resilient Seated Gate Valves have emerged as a preferred choice due to their robust design and exceptional sealing capabilities. According to a market research report by Global Market Insights, the gate valve market is expected to exceed $5 billion by 2026, driven by the increasing demand for resilient materials in infrastructure development. This growth highlights the importance of choosing the right valve, as the quality of valve components directly influences operational efficiency and maintenance costs. With their resilience to environmental stressors and superior performance metrics, understanding the key aspects of Din 3352 F4 Resilient Seated Gate Valves is essential for professionals looking to optimize their systems and ensure long-term functionality. This article presents the ultimate checklist to guide you through the decision-making process, ensuring you make an informed choice.

When selecting DIN 3352 F4 resilient seated gate valves, several key considerations should be kept in mind to ensure optimal performance and longevity. Firstly, the material of the valve is crucial. Typically, these valves feature ductile iron bodies with resilient seat elements, which contribute to their durability and resistance to wear.

Evaluating the specific environmental conditions and the media that will pass through the valve, such as water or sewage, will help in choosing the right material that can handle potential corrosive elements.

Another important aspect is the valve’s pressure rating. DIN 3352 F4 valves are known for their reliable sealing capabilities, but it's vital to match the pressure rating with the system's requirements. Consideration of the maximum working pressure and the valve's resistance to pressure surges is essential for avoiding future operational issues. Additionally, assess the valve design features, such as the stem and disc configuration, to ensure they align with your operational needs while facilitating ease of maintenance and installation processes.

When selecting DIN 3352 F4 resilient seated gate valves, understanding their technical specifications is crucial to ensuring optimal performance in various applications. These valves are designed to provide reliable sealing and excellent durability, making them ideal for water supply, drainage, and other industrial settings. The key specifications to consider include body material, sealing mechanisms, pressure ratings, and temperature ranges, as these factors directly influence the valve's ability to perform under different conditions.

Body material is particularly important, as it affects the valve's resistance to corrosion and its overall lifespan. Common materials include ductile iron and cast iron, often coated for enhanced protection. Additionally, the sealing interface, where the valve disk meets the seat, should be examined for compatibility with the fluids it will encounter. Pressure and temperature ratings indicate the operational limits of the valve, ensuring that it can withstand the required service conditions without failure. By thoroughly understanding these specifications, users can make informed decisions that enhance system reliability and efficiency.

When selecting Din 3352 F4 resilient seated gate valves, the material options play a critical role in both durability and performance. The choice of materials directly impacts the valve's lifespan and its ability to withstand various operational conditions. According to a report by the American Society of Mechanical Engineers (ASME), valves made from ductile iron with an epoxy coating show a corrosion resistance lifespan extending up to 20% longer than traditional cast iron valves in harsh environments. This significant enhancement in longevity is essential for industries where maintenance shutdowns can lead to considerable operational costs.

Moreover, the performance characteristics of the materials influence the valve's sealing capabilities and flow efficiency. A study published in the Journal of Pipeline Systems Engineering and Practice highlights that resilient seated gate valves constructed with high-grade elastomers exhibit superior sealing performance, reducing leakage rates by over 50% compared to those using standard rubber materials. This improved efficiency not only enhances the system's overall operation but also compliance with environmental regulations, further underscoring the importance of selecting the right materials for reliable performance in demanding applications.

When selecting Din 3352 F4 resilient seated gate valves, understanding the importance of sizing and pressure ratings is crucial.

Proper sizing of valves ensures they can handle the required flow rates without causing excessive turbulence or wear. Incorrectly sized valves may lead to operational inefficiencies and increased energy costs. Additionally, pressure ratings play a vital role in ensuring that the valve can withstand the operating conditions within a system. This is especially pertinent in industries such as aerospace, where the market for valves is projected to grow significantly, highlighting an increased emphasis on precision and reliability in valve selection.

Recent research in valve technology, including the study of pressure-relief valves for two-phase flow, underscores the importance of proper sizing and ratings for optimal performance. Accurate sizing not only contributes to the overall efficiency of fluid systems but also enhances safety by preventing failures due to pressure surges. By focusing on these critical aspects during the selection process, organizations can ensure that their valve solutions meet both operational demands and safety standards, ultimately leading to enhanced performance and reduced lifecycle costs.

When installing resilient seated gate valves, adhering to best practices is critical to ensuring their optimal performance and longevity. According to a report by the American Water Works Association (AWWA), improper installation is a leading cause of valve failures, which can result in costly repairs and system downtime. Ensuring the valve is properly aligned and the seating surfaces are clean during installation can significantly minimize the risk of future leaks and failures. Furthermore, the use of correct torque settings is vital; excessive torque can deform the valve and affect its functionality, while insufficient torque may fail to create a proper seal.

Maintenance also plays a key role in the lifespan of resilient seated valves. A study from the International Journal of Hydraulic Engineering recommends regular inspections and proactive maintenance schedules, which can identify potential issues before they escalate. Routine checks should focus on the operating mechanism, including the ease of operation and any signs of corrosion or wear. Data indicates that valves with scheduled maintenance can last up to 30% longer than those without, making a robust maintenance program essential for asset management in water distribution systems. By integrating these best practices into both the installation and maintenance phases, operators can ensure the reliability and efficiency of resilient seated gate valves in their systems.