+86 19720579616

+86 19720579616

Zalo

Zalo

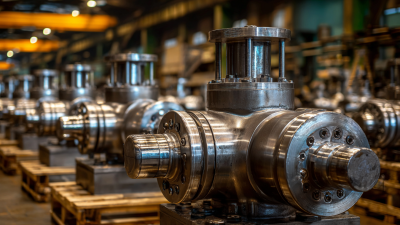

Selecting the right forged steel valves is crucial for enhancing the efficiency and safety of industrial operations. According to a recent report by the Global Valve Market Research, the demand for forged steel valves is projected to grow at a CAGR of 5.2% over the next five years, driven by their superior strength and durability compared to cast valves. These valves are essential in various sectors, including oil and gas, water treatment, and power generation, where high pressure and temperature conditions are prevalent. Choosing the right forged steel valves not only ensures compliance with industry standards but also significantly reduces maintenance costs and downtime. In this blog, we will discuss the seven best practices to consider when selecting forged steel valves tailored to your industrial needs, helping you make informed decisions that align with your operational goals.

When selecting forged steel valves for industrial applications, several key factors must be taken into account to ensure optimal performance and longevity. Firstly, understanding the operating conditions, such as temperature and pressure ratings, is crucial. According to the American Society of Mechanical Engineers (ASME), valves must meet specific pressure-temperature ratings defined in the ASME B16.34 standard. This compliance ensures that the valves can withstand extreme conditions without failure, which is critical for maintaining system integrity and safety.

Another critical factor is the material selection. Various grades of forged steel, such as ASTM A105 and ASTM A182, offer different levels of corrosion resistance and strength. A recent report by the Metal Connector Association highlighted that improper material choice could lead to increased maintenance costs, with some industries reporting upwards of 30% of their operational expenses tied to valve failures and replacements. Additionally, compatibility with the media being transported—whether it be water, steam, or corrosive chemicals—plays a vital role in ensuring the longevity and reliability of the valves. By thoroughly evaluating these factors, industries can avoid costly downtime and optimize their operations.

This chart illustrates the importance of various factors when selecting forged steel valves for industrial purposes, based on a survey of industry professionals.

When selecting forged steel valves for industrial applications, understanding valve specifications is critical for ensuring optimal performance. According to a report by MarketsandMarkets, the global valve market is projected to reach $83.4 billion by 2026, underscoring the importance of precise specifications to meet industry demands. Valves must be tailored to specific parameters such as pressure rating, temperature range, and the type of fluid they will handle, which can significantly affect system efficiency and durability.

High-quality valves are designed to withstand extreme conditions, and their specifications can directly influence maintenance costs and operational uptime. Data from the American Society of Mechanical Engineers (ASME) indicates that improper valve selection can lead to a 10-15% increase in overall system failure rates. Therefore, engineers must ensure that valve materials, sizes, and designs are compatible with the intended application, optimizing both reliability and performance.

Selecting a valve with precise specifications not only enhances system safety but also contributes to energy efficiency, ultimately resulting in lower operational costs.

When selecting forged steel valves for specific industrial applications, it’s crucial to understand the distinct requirements of your operations. Different types of valves, such as ball valves, gate valves, and plug valves, serve unique functions and are designed for varying scenarios. The choice of valve should align with the fluid being controlled, the pressure conditions, and the temperature range. For instance, if your application involves corrosive substances, opting for a valve with a PTFE lining could be beneficial; this material provides enhanced protection against chemical degradation.

The market for PTFE-lined plug valves is expected to witness significant growth, projected to rise from $64.14 million in 2024 to $84.01 million by 2032, reflecting a compound annual growth rate of 3.4%. This trend underscores the increasing demand for reliable and resilient valve solutions across industrial sectors. When choosing valves, it is essential to consider factors such as durability, maintenance requirements, and the specific operational context to ensure optimum performance and longevity. Prioritizing these criteria will lead to more effective and efficient industrial processes.

| Valve Type | Applications | Pressure Rating (psi) | Temperature Range (°F) | Material Composition |

|---|---|---|---|---|

| Ball Valve | Oil & Gas, Water Supply | 1500 | -20 to 300 | A105, A182 |

| Gate Valve | Wastewater Management, HVAC | 1000 | 0 to 250 | A216 WCB |

| Globe Valve | Fire Protection, Oil Refineries | 600 | -40 to 200 | A105 |

| Check Valve | Pipelines, Water Systems | 800 | -20 to 250 | A351 CF8M |

| Butterfly Valve | Chemical Processing, Water Distribution | 300 | -10 to 150 | A126 Class B |

| Pressure Relief Valve | Steam Systems, Oil & Gas | 2000 | 0 to 450 | A216 WCB |

| Y-Strainer | Pipeline Filtration, Water Treatment | 150 | -20 to 500 | A105 |

When selecting forged steel valves for industrial applications, understanding the reputation of the manufacturer and the quality standards of their products is crucial. A recent report from the International Valve Manufacturers Association indicates that nearly 30% of valve failures in industrial settings are attributed to substandard manufacturing practices and materials.

Therefore, choosing a manufacturer with a solid reputation for reliability and quality can significantly reduce the risk of failures and downtime in your operations.

Certification is another key aspect to consider. Manufacturers that adhere to internationally recognized standards, such as ASME (American Society of Mechanical Engineers) and ISO (International Organization for Standardization), ensure that their products meet stringent quality and safety regulations. According to a study published by the Valve World magazine, valves produced by certified manufacturers showed a 40% lower failure rate over a five-year period compared to those from non-certified sources. This emphasizes the importance of evaluating not just the product, but also the manufacturer’s commitment to industry standards and continuous improvement.

When it comes to ensuring the longevity of forged steel valves, implementing best maintenance practices is crucial. Regular inspection and monitoring of the valves can help detect issues early, preventing costly downtimes and ensuring optimal performance. One effective approach is to establish a routine maintenance schedule that includes cleaning, lubricating, and tightening components. This proactive stance not only enhances operational efficiency but also extends the lifespan of the valves.

Moreover, selecting the right type of valve for specific applications can significantly impact maintenance needs. The recent discussions around the differences between cast and forged production highlight the importance of understanding the cost-performance ratio for specific industrial applications. Forged steel valves often provide greater strength and resistance to fatigue, which can be advantageous in high-pressure systems. By aligning the valve selection with maintenance practices and the specific demands of your application, you can create a resilient and efficient system that minimizes the need for extensive repairs over time.