+86 19720579616

+86 19720579616

Zalo

Zalo

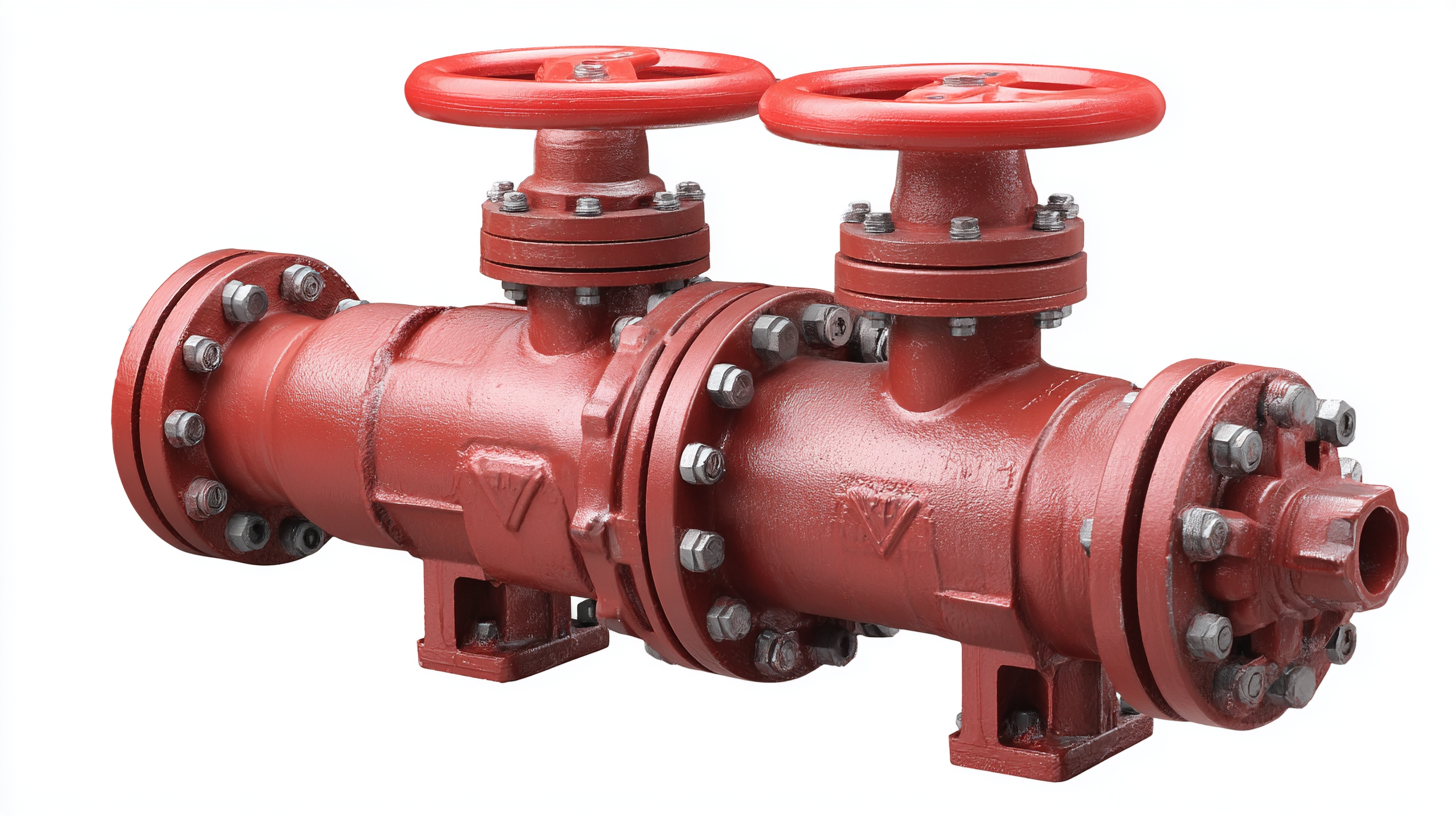

In the rapidly evolving industrial landscape, the demand for reliable and efficient valve solutions is paramount, particularly for applications requiring enhanced performance and minimal leakage. According to a recent report by MarketsandMarkets, the global valve market is projected to reach $100 billion by 2025, driven by the need for advanced infrastructure across various sectors. Among the diverse range of valves, Din Bellows Sealed Gate Valves have garnered significant attention due to their superior sealing capabilities and reduced maintenance requirements. These valves are designed to prevent leakage along the shaft, which is crucial for industries such as oil and gas, water treatment, and chemical processing. Their unique construction not only ensures safety and reliability but also enhances operational efficiency, making them a preferred choice for engineers and decision-makers alike. In this blog, we will explore the 7 best Din Bellows Sealed Gate Valves that stand out in terms of performance and reliability, ensuring that you can make informed choices for your projects.

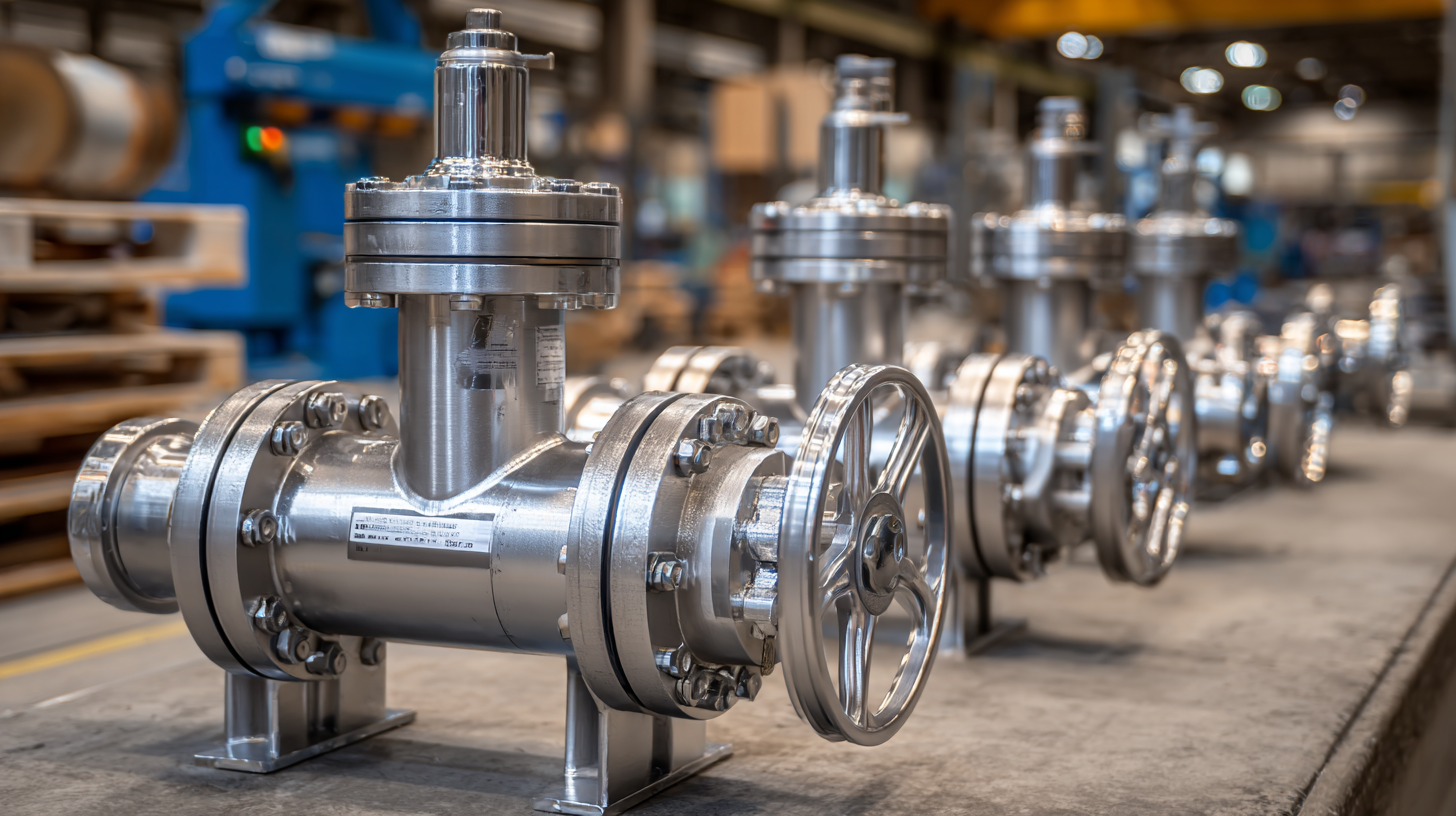

When selecting DIN bellows sealed gate valves, several top features are crucial for enhanced performance in various applications. Firstly, the material composition plays a vital role in ensuring durability and resistance to corrosive environments. Valves made from high-quality stainless steel or specialized alloys are preferable as they can withstand extreme temperatures and pressure fluctuations without compromising their integrity.

Another critical feature to consider is the bellows design itself. A robust bellows system ensures a tight seal, minimizing the risk of leakage, which is essential in industries dealing with hazardous or valuable fluids. Look for designs that offer flexibility while maintaining high strength and reliability. Additionally, effective construction and quality control processes contribute significantly to the longevity of the valves, making it important to choose manufacturers known for their precision engineering.

Finally, ease of installation and maintenance should not be overlooked. Valves that come with clear installation instructions and are compatible with standard piping will save time and reduce costs. Furthermore, consider features such as actuation options and automation compatibility, which can enhance operational efficiency and facilitate remote monitoring. By focusing on these key features, you can select the best DIN bellows sealed gate valves tailored to your specific requirements.

When it comes to ensuring the highest performance in fluid control systems, DIN bellows sealed gate valves have emerged as a superior choice for engineers and designers alike. This comparative analysis delves into the top seven options available on the market, taking into consideration factors such as material quality, design efficiency, and operational reliability. The unique design of bellows sealed gate valves minimizes the risk of leakage, making them ideal for critical applications where maintaining integrity is paramount.

In our review, we examine each valve's specifications and performance metrics, highlighting their advantages and identifying key differentiators. For instance, certain models offer enhanced corrosion resistance, while others boast superior temperature tolerance, making them suitable for extreme environments. By providing a focused comparison, this analysis aims to equip industry professionals with the insights needed to select the best valve for their specific needs, ultimately leading to improved system performance and longevity.

DIN bellows sealed gate valves are designed to provide superior sealing capabilities, enhancing overall system performance by preventing leakage. The incorporation of a bellows seal isolates the valve's operating mechanism from the fluid, reducing the risk of contamination and improving the longevity of the valve and the system. This is particularly crucial in applications where media purity is essential, such as in the pharmaceutical or food processing industries.

Tip: When selecting a DIN bellows sealed gate valve, ensure that the materials used for both the bellows and the body are compatible with the working fluid. This compatibility is essential to mitigate corrosion and extend the valve's service life.

Another significant advantage of these valves is their ability to handle high pressure and temperature variations without compromising performance. The robust design allows for effective use in dynamic systems, where consistent performance is critical. Operators can rely on these valves to maintain system integrity, even in challenging conditions.

Tip: Regular maintenance and inspection of DIN bellows sealed gate valves can help identify any potential issues early, allowing for timely intervention and minimizing downtime. Always refer to the manufacturer’s guidelines for the best maintenance practices specific to your application.

When it comes to ensuring the optimal functionality of DIN bellows sealed gate valves, regular maintenance is key. These valves are designed to prevent leakage and provide enhanced performance in various applications, but without proper upkeep, they may not operate as efficiently. One critical maintenance tip is to regularly inspect the bellows for any signs of wear or damage. This can help detect potential problems early on and prevent costly downtime.

Another important aspect of maintenance is to keep the valve clean and free from debris. Accumulated dirt can hinder the valve's movement and lead to malfunctions. Utilizing mild cleaning agents and avoiding abrasive materials during cleaning can help preserve the valve’s integrity. Additionally, lubricating the valve components periodically can reduce friction and enhance their operational longevity, ensuring a smooth and reliable performance every time. By following these maintenance tips, users can extend the lifespan of their DIN bellows sealed gate valves and ensure they function at their best.

DIN bellows sealed gate valves are notable for their exceptional sealing capabilities and versatility across various applications. These valves are widely utilized in industries such as oil and gas, chemical processing, and water treatment, where leak prevention and reliability are crucial. Their design includes a bellows that ensures a tight seal, making them ideal for handling hazardous and corrosive materials, thereby enhancing operational safety and efficiency.

When considering the integration of DIN bellows sealed gate valves, it is essential to evaluate the specific requirements of your application. Look for valves that comply with relevant industry standards and have been tested for durability under the conditions they will face. Additionally, regular maintenance and inspection can prolong the lifespan of these valves and ensure optimal performance.

Tip: Always consult with a valve specialist to select the appropriate model that matches your system's pressure and temperature parameters, as this is crucial for achieving the desired performance level. Furthermore, when installing these valves, ensure that they are correctly oriented based on fluid flow direction to avoid operational issues.