+86 19720579616

+86 19720579616

Zalo

Zalo

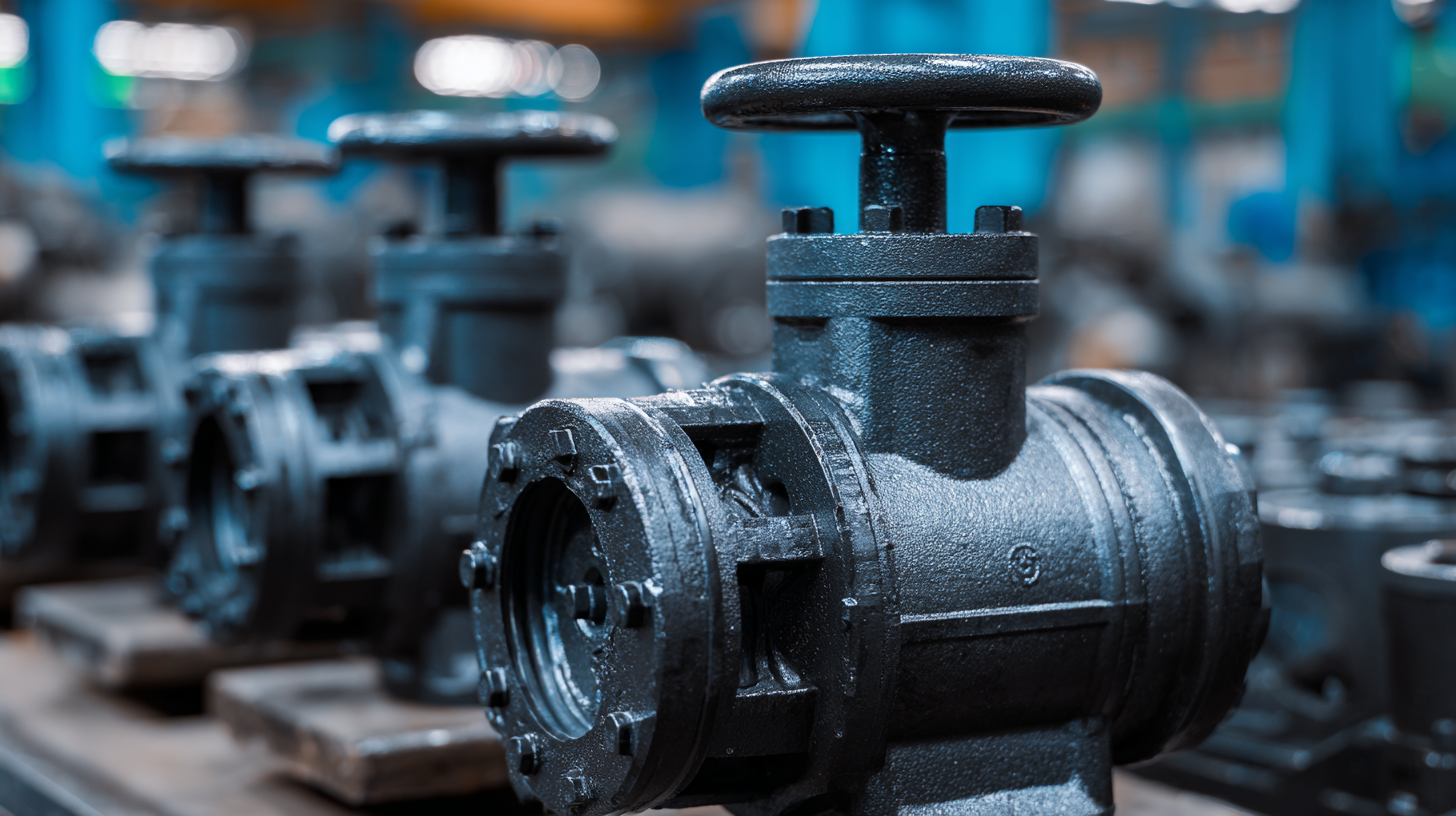

In the realm of industrial applications, the efficiency and reliability of valve systems are paramount to maintaining operational integrity and safety. Among the various types of valves, Din Bellows Sealed Gate Valves have emerged as a preferred choice due to their unique design and effectiveness in preventing leakage.

According to a recent report by the Valves Market Research Institute, the global demand for sealed valves is projected to grow steadily, driven by the increasing need for high-performance sealing solutions in critical processes. These valves are engineered to provide superior performance in sectors such as oil and gas, water treatment, and chemical processing, where the risk of contamination is a significant concern.

This blog will explore the characteristics and applications of Din Bellows Sealed Gate Valves, providing insights into how they can enhance operational efficiency while ensuring environmental compliance.

Bellows sealed gate valves are increasingly recognized for their effectiveness in industrial applications, particularly due to their unique ability to provide a robust barrier against leakage, which is crucial in environments where process integrity is paramount. According to recent market analyses, the demand for welded metal bellows is projected to grow significantly, with a focus on materials such as stainless steel and high nickel alloys. These materials not only enhance the performance of bellows sealed gate valves but also contribute to extended service life and reliability under extreme conditions.

In industrial settings, the benefits of using bellows sealed gate valves are manifold. They minimize the risk of contamination in sensitive processes, which is especially vital in sectors like pharmaceuticals and food processing. The Mechanical Seals Market report highlights that the increasing need for reliable sealing solutions in high-vacuum applications further underlines the significance of bellows technology. With their ability to maintain process stability and prevent leakage, bellows sealed gate valves are poised to become a standard solution in various industrial applications, emphasizing the growing trend toward enhanced safety and efficiency.

In the realm of industrial applications, the importance of high-quality bellows sealed gate valves cannot be overstated. These valves are renowned for their ability to withstand extreme conditions, thus ensuring optimal performance and durability. A recent industry report highlights that the demand for bellows sealed gate valves is expected to grow significantly, driven by the increasing need for effective sealing in critical applications, including chemical processing and energy.

Key features of top-tier bellows sealed gate valves include exceptional leak-proof design, the ability to handle high temperatures and pressures, and corrosion resistance. The innovative designs seen in recent patents emphasize advancements such as dual sealing mechanisms which further enhance performance reliability. For instance, the introduction of corrosion-resistant materials has been pivotal in extending the lifecycle of valve bodies, catering to the stringent requirements of various industrial sectors.

Furthermore, the trend towards domestic production of valve components is evident, with many manufacturers achieving impressive local content percentages, minimizing supply chain vulnerabilities. The ongoing innovation in valve technology not only elevates the standards within the valve manufacturing industry but also positions companies to meet the evolving demands of modern industrial applications effectively.

When assessing the market for bellows sealed gate valves, a comparative analysis between Chinese manufactured valves and their global competitors reveals significant insights. According to a 2022 report by the Market Research Future, the global valve market is projected to reach $93.4 billion by 2026, with Asia-Pacific, led by China, accounting for a substantial share due to its robust manufacturing capabilities and cost efficiencies. Chinese manufacturers have made noteworthy advancements in technology, with many companies adopting ISO certifications to meet international quality standards, which enhances their competitiveness on a global scale.

However, when considering factors such as material quality, durability, and service life, global competitors, particularly those from European and North American markets, often demonstrate a slight edge. A comprehensive analysis by an industry expert indicated that while Chinese valves account for approximately 30% lower initial costs, major brands from the US and Germany exhibit lower failure rates in critical applications, leading to higher overall reliability and lower lifecycle costs. This intricate balance of price versus performance is crucial for industries seeking effective solutions in demanding environments, highlighting the importance of thorough evaluation when selecting bellows sealed gate valves for industrial applications.

| Valve Type | Material | Pressure Rating (PN) | Temperature Range | Application | Manufacturing Origin |

|---|---|---|---|---|---|

| DIN 3356 | Stainless Steel | 16 | -10°C to 100°C | Water and Wastewater | China |

| DIN 3356 | Carbon Steel | 25 | -15°C to 180°C | Oil and Gas | Global |

| DIN 3356 | Alloy Steel | 40 | -20°C to 250°C | Chemical Processing | China |

| DIN 3356 | Bronze | 10 | -10°C to 80°C | Steam and Heating | Global |

| DIN 3356 | PVC | 6 | 0°C to 50°C | Water Treatment | China |

Bellows sealed gate valves play a crucial role in various industrial applications, ensuring leak-free operation while handling fluids and gases. Their unique design incorporates a flexible metal bellows, which provides a secondary barrier against leakage, making them ideal for industries dealing with hazardous materials or high-purity processes. In the chemical manufacturing sector, for instance, these valves prevent contamination and protect the environment by containing aggressive chemicals and volatile substances.

Moreover, the oil and gas industry benefits significantly from the reliability of bellows sealed gate valves. These valves can withstand extreme pressures and temperatures, making them suited for upstream exploration and downstream processing. Their ability to maintain integrity in demanding conditions reduces the risk of leaks, which is essential for operational efficiency and safety.

Additionally, the power generation sector utilizes these valves in steam and water systems, where precision control is critical for optimal performance. As industries continue to seek safer and more effective solutions, the demand for high-quality bellows sealed gate valves will undoubtedly rise.

When it comes to the production of DIN bellows sealed gate valves, quality assurance is paramount. These valves are critical components in various industrial applications, where preventing leaks and ensuring operational safety are non-negotiable. The manufacturing process begins with the selection of high-grade materials that can withstand extreme conditions, including high pressure and aggressive media. Rigorous testing of these materials helps in assessing their durability and resistance, setting a strong foundation for the quality of the final product.

Quality assurance measures extend beyond material selection. Manufacturers often implement stringent testing protocols during production, including hydrostatic and pneumatic tests to verify the integrity of the seals. Additionally, regular inspections at various stages of the manufacturing process are essential. These inspections may involve microscopy examinations and non-destructive testing techniques to detect any potential defects early on. By integrating these practices, manufacturers can ensure that their DIN bellows sealed gate valves not only meet industry standards but also provide reliable performance in demanding environments.