+86 19720579616

+86 19720579616

Zalo

Zalo

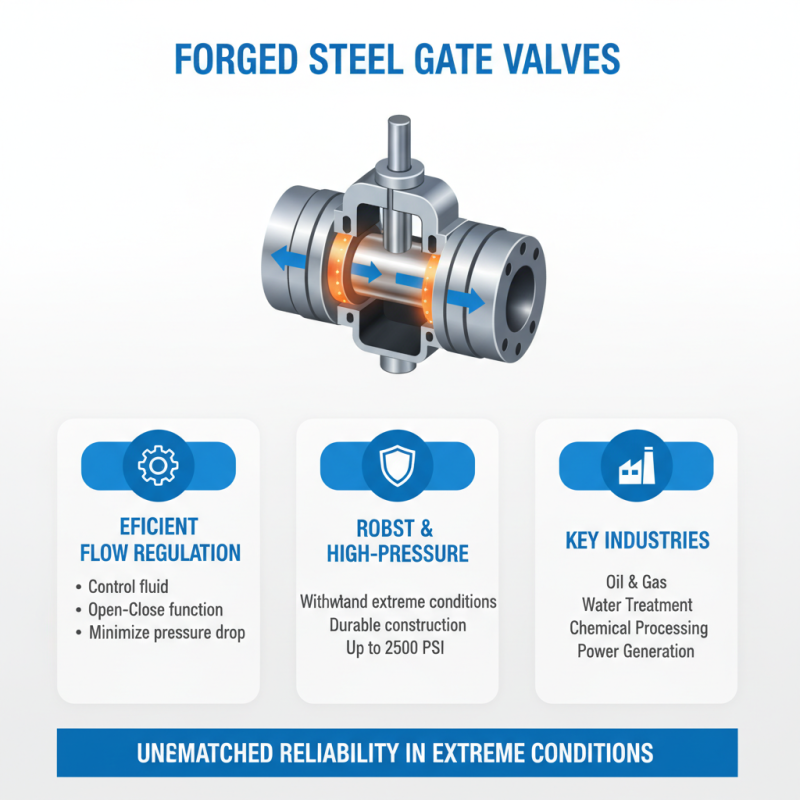

Forged Steel Gate Valves are essential in many industries. They offer great durability and strength. This is crucial in high-pressure and high-temperature applications. Their design ensures a tight seal, preventing leaks.

One major advantage of Forged Steel Gate Valves is their resistance to corrosion. In harsh environments, they perform well. They can withstand challenging chemicals, extending their life span. This reliability is often overlooked, yet it greatly impacts maintenance costs.

Another benefit is their ease of operation. Many models feature a simple, user-friendly mechanism. Operators often appreciate this, as it simplifies valve control. However, not all Forged Steel Gate Valves are created equal. Some may struggle under extreme conditions, so careful selection is key. In summary, understanding these valves can lead to better choices and improved efficiency.

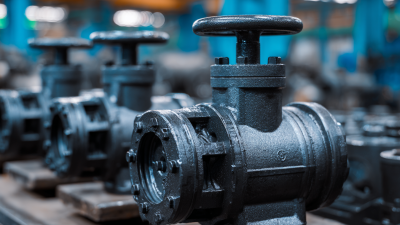

Forged steel gate valves are crucial in many industries. They are designed to regulate fluid flow efficiently. Their robust construction makes them ideal for high-pressure applications. Many facilities use them in oil and gas, water treatment, and chemical processing. The ability to withstand extreme conditions is impressive. These valves offer reliability that is often unmatched by other materials.

The manufacturing process of forged steel enhances its durability. This means these valves can resist corrosion. However, there are factors to consider. Installation can be challenging, requiring skilled labor. In some cases, maintenance can seem excessive due to the materials involved. Yet, the performance benefits often outweigh these concerns. Users must ensure compatibility with their systems. Regular inspections help in maintaining long-term functionality.

Forged steel gate valves offer remarkable advantages due to their distinctive characteristics. The high strength and toughness of forged steel significantly enhance valve performance. According to the American Society of Mechanical Engineers (ASME), forged steel’s yield strength can exceed 400 MPa. This durability means that valves can operate in high-pressure environments without compromising integrity.

Another key feature is resistance to fatigue and thermal shock. Forged steel valves can endure significant temperature variations. A report from the International Journal of Pressure Vessels and Piping highlights that these valves perform well in temperatures ranging from -50°C to 500°C. This versatility allows industries to adapt to various operational conditions.

However, the manufacturing process can be a double-edged sword. While forging enhances grain structure and strength, it also requires precision. Any flaw in the forging process can lead to potential failures. Moreover, the initial cost of forged steel gate valves is higher than other materials. Industries need to weigh these factors carefully. Understanding the balance between performance and cost is crucial for effective decision-making.

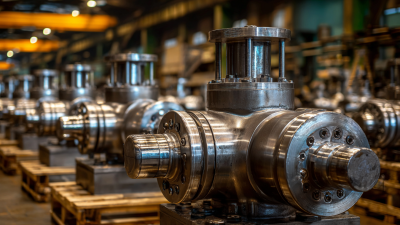

Forged steel gate valves are known for their impressive durability and strength. They are made through a process that involves shaping steel at high temperatures. This method increases the metal's density and eliminates any structural weaknesses. As a result, these valves can withstand high pressures and aggressive environments. They can endure significant wear over time, making them a reliable choice in industrial applications.

Not all forged steel gate valves are created equal, though. Some might experience issues like corrosion if not properly maintained. Selecting the right type and ensuring proper installation are crucial. While they generally offer longevity, users should always consider their specific needs and environments. Regular inspections can prevent unexpected failures, leading to costly downtime. It's essential to strike a balance between durability and upkeep to maximize performance and lifespan.

Forged steel gate valves are a preferred choice in various industries for their cost-effectiveness and long-term savings. According to a recent industry report, these valves can reduce maintenance costs by up to 30% compared to other materials. Their robust construction minimizes wear and tear, extending their lifespan. With proper care, forged steel valves can last over 20 years, providing substantial savings on replacements and repairs.

Moreover, the initial investment in forged steel valves is often offset by their durability. For example, a study revealed that using forged steel instead of cast iron reduced overall operational costs by about 15%. This is significant for industries that rely on tight budgets. The reliability of forged steel valves prevents unexpected breakdowns, which could lead to costly downtime.

However, not all installations have gone smoothly. Some facilities reported issues with corrosion, affecting performance. Regular inspections can help identify these problems before they escalate. Investing in higher quality materials initially might seem steep, but it is crucial for long-term savings. Ignoring this can lead to unexpected expenses and reduced efficiency. Craftsmanship matters in valve manufacturing; oversight in this area could lead to premature failures.

Forged steel gate valves play a crucial role in many industries. Their durability and strength contribute to a more sustainable approach to water and gas management. When properly engineered, these valves can minimize leaks and reduce waste. This is essential for improving overall environmental health.

Consider how long these valves last. They withstand harsh conditions, cutting down on frequent replacements. However, improper maintenance can lead to corrosion. Regular checks are vital. Small leaks can become big problems over time.

Tips: Always inspect your valves regularly. Clean them often to prevent buildup. If you notice any issues, address them immediately. It’s better to fix small problems than to deal with larger ones later. Just a bit of attention can greatly enhance the lifespan of forged steel gate valves.

The production of forged steel valves typically uses less energy than casting processes. However, recycling is critical. Many manufacturers are adopting recycling practices. This shift reduces raw material consumption and reduces waste. Be aware that not all suppliers make sustainable choices. Always do your research before selecting materials. Your decisions impact the environment.