+86 19720579616

+86 19720579616

Zalo

Zalo

In recent years, the industrial sector has witnessed a significant shift towards the adoption of advanced materials and technologies to enhance operational efficiency and reliability. Among these innovations, Forged Steel Ball Valves have emerged as a top choice for many applications due to their superior performance characteristics. According to industry reports, the global valve market is projected to reach $84.6 billion by 2027, with a substantial contribution coming from forged steel valves due to their robustness and durability. Forged Steel Ball Valves exhibit remarkable strength and resistance to extreme pressures and temperatures, making them ideal for critical applications in oil and gas, chemical processing, and power generation industries.

Moreover, the advantages of using Forged Steel Ball Valves extend beyond just mechanical strength. Research suggests that the use of high-quality forged steel can lead to improved flow characteristics, reduced maintenance costs, and extended service life, which are crucial factors for companies aiming to optimize their operations. With a growing emphasis on safety and efficiency, the demand for these valves is expected to rise, as industries are increasingly aware of their benefits. This article explores the top five benefits of Forged Steel Ball Valves and how their application is driving enhanced performance across various industrial settings.

Forged steel ball valves are critical components in various industrial applications due to their robustness and superior functionality. Unlike traditional valves, these valves are constructed from a single piece of steel, which enhances their strength and durability. The design features a spherical disc that allows for smooth flow control, enabling precise regulation of fluid dynamics. Forged steel ball valves provide an effective sealing mechanism, minimizing the risk of leaks in high-pressure environments, thus ensuring operational safety and reliability.

The functionality of forged steel ball valves extends beyond mere flow control; they can be used for on/off operations with minimal resistance. Their design allows for quick quarter-turn movement, which not only simplifies the operation but also reduces the risk of wear and tear over time. Additionally, these valves can handle various media, including corrosive substances, making them versatile for diverse industrial sectors such as oil and gas, chemical processing, and water treatment. Their ability to maintain structural integrity under extreme temperatures and pressures further solidifies their role as a preferred choice in complex engineering systems, where safety and efficiency are paramount.

Forged steel ball valves are increasingly recognized for their enhanced strength and durability, making them a top choice in various industrial applications. The forging process provides superior mechanical properties compared to cast components, resulting in valves that are not only more robust but also capable of withstanding high pressure and temperature conditions. This durability is critical in industries where reliability and performance are paramount, such as oil and gas, chemical processing, and power generation.

One of the key advantages of forged steel ball valves is their resistance to wear and tear. The solid structure of forged steel minimizes the risk of defects and ensures a longer service life, translating to lower maintenance costs over time. Industries that prioritize operational efficiency benefit significantly from this reliability, as reduced downtime can lead to enhanced productivity.

Tips: When selecting forged steel ball valves, consider the specific requirements of your application, including operating pressure and temperature. It's also vital to ensure compatibility with the fluids being transported to prevent premature wear. Regular maintenance checks can further enhance the lifespan of these valves, ensuring that they continue to operate effectively under demanding conditions.

| Benefit | Description | Application Examples | Impact on Performance |

|---|---|---|---|

| Enhanced Strength | Forged steel provides superior strength compared to cast valves, allowing them to withstand high pressure and extreme temperatures. | Oil & Gas, Chemical Processing | Reduced risk of failure in high-stress environments, leading to increased safety and reliability. |

| Durability | Forged steel ball valves are designed to last longer, minimizing the need for frequent replacements. | Water Treatment, Power Generation | Lower maintenance costs and downtime due to extended service life. |

| Corrosion Resistance | Many forged steel valves are treated to resist corrosion, which is crucial in harsh environments. | Marine Applications, Wastewater Management | Increased longevity and reduced replacement frequency due to corrosion-related failures. |

| Tight Sealing | Forged steel ball valves provide excellent sealing capabilities, preventing leaks and maintaining pressure. | Energy Sector, Food Processing | Enhanced operational efficiency and safety through leak prevention. |

| Versatility | Can be used in a wide range of applications due to various design options and standards. | Manufacturing, HVAC Systems | Flexible usage in different industrial scenarios enhances overall system effectiveness. |

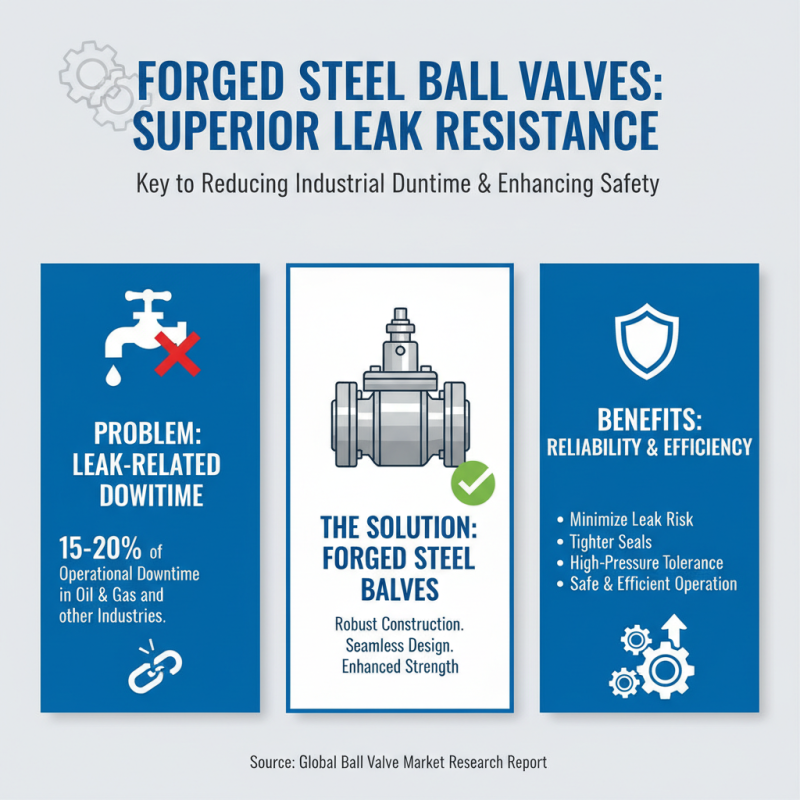

Forged steel ball valves are gaining popularity in industrial applications primarily due to their superior leak resistance. According to a report by the Global Ball Valve Market Research, leak-related issues account for approximately 15-20% of operational downtime in various industries, particularly in oil and gas. With their robust construction, forged steel ball valves minimize the risk of leaks significantly compared to other valve types. Their seamless design and enhanced strength allow these valves to maintain tighter seals under high pressure, thus ensuring safe and efficient operations.

The importance of leak resistance in industrial environments cannot be overstated. Studies indicate that even minor leaks can lead to substantial financial losses, exceeding millions of dollars annually and impacting environmental safety. Forged steel ball valves, with their superior materials and precision engineering, are designed to withstand extreme temperature variations and aggressive chemical environments. Data from the Industrial Valve Association further highlights that implementing these valves can lead to a reduction in leakage incidents by up to 40%, showcasing their effectiveness in enhancing overall operational safety and efficiency. In an industry where reliability is critical, these features make forged steel ball valves an essential component in modern industrial applications.

Forged steel ball valves are essential components in a wide array of industrial applications due to their unparalleled versatility. These valves are engineered to withstand extreme conditions, making them suitable for various sectors, including oil and gas, petrochemical, and water treatment. Their robust design allows them to handle high pressure and temperature, ensuring optimal performance even in the most demanding environments. This reliability reduces maintenance costs and downtime, creating a more efficient workflow across different industries.

Moreover, the adaptability of forged steel ball valves is evident in their diverse operational requirements. Whether used in high-flow pipelines or intricate machinery, these valves can be tailored to fit specific needs, including size, connection types, and sealing materials.

This customization ensures compatibility with various fluids and gases, enhancing their functionality in multiple settings. As industries continue to evolve, the capacity of forged steel ball valves to adapt to new technologies and processes makes them a favored choice among engineers and operators seeking efficient and effective solutions.

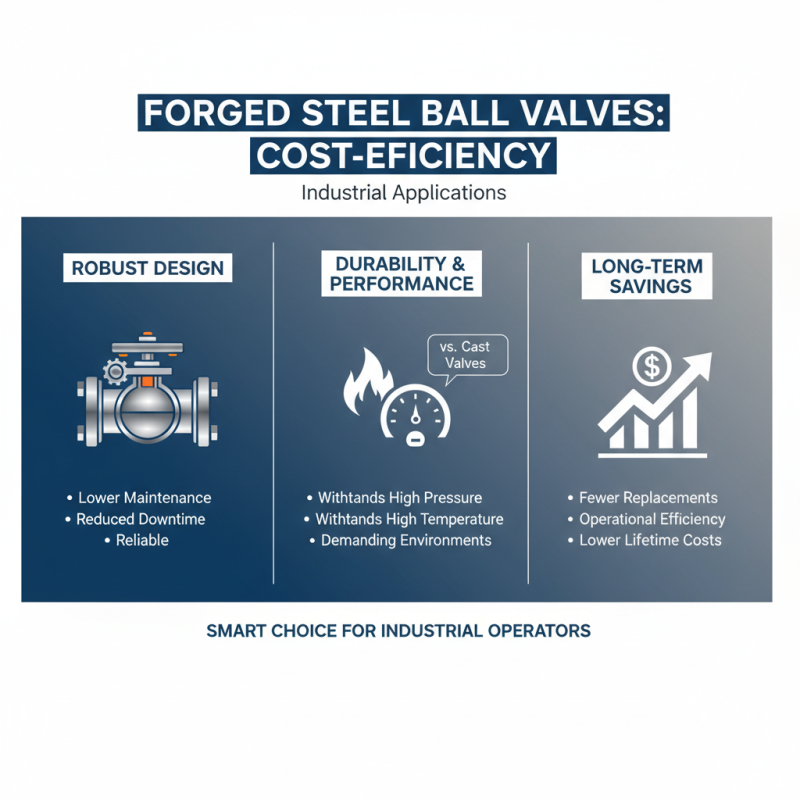

Forged steel ball valves are increasingly recognized for their cost-efficiency in industrial applications. Their robust design and manufacturing process result in lower maintenance requirements compared to other valve types, which can lead to significant cost savings over time. Unlike cast valves, forged steel valves can endure high pressures and temperatures, making them a reliable choice for demanding environments. This durability means that industrial operators can benefit from fewer operational disruptions and reduced need for replacements, translating to lower lifetime costs.

Moreover, the long-term benefits of using forged steel ball valves extend beyond mere savings. These valves feature excellent flow characteristics and a tight sealing capability, ensuring reliable performance that minimizes the risk of leaks. This is particularly vital in industries where safety and environmental concerns are paramount. The reduced need for frequent replacements not only cuts expenses but also contributes to sustainability efforts by lowering the frequency of manufacturing and disposal processes. As industries continue to prioritize efficiency and environmental responsibility, the adoption of forged steel ball valves stands out as a strategic enhancement to both operational and financial performance.